Oscillating tooth reduction gear hub motor

A technology of in-wheel motor and movable tooth deceleration, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of low reliability, high noise, small reduction ratio range, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

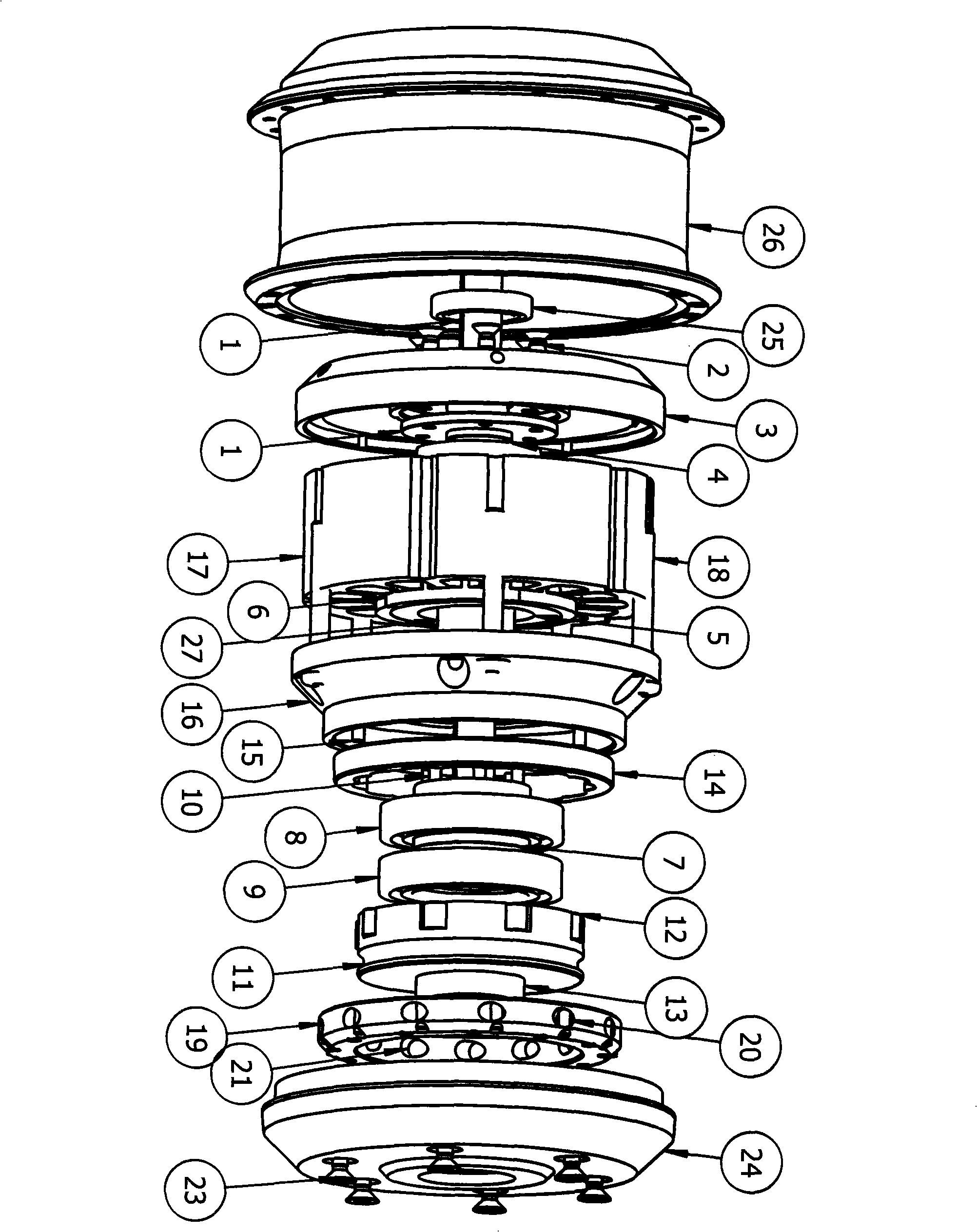

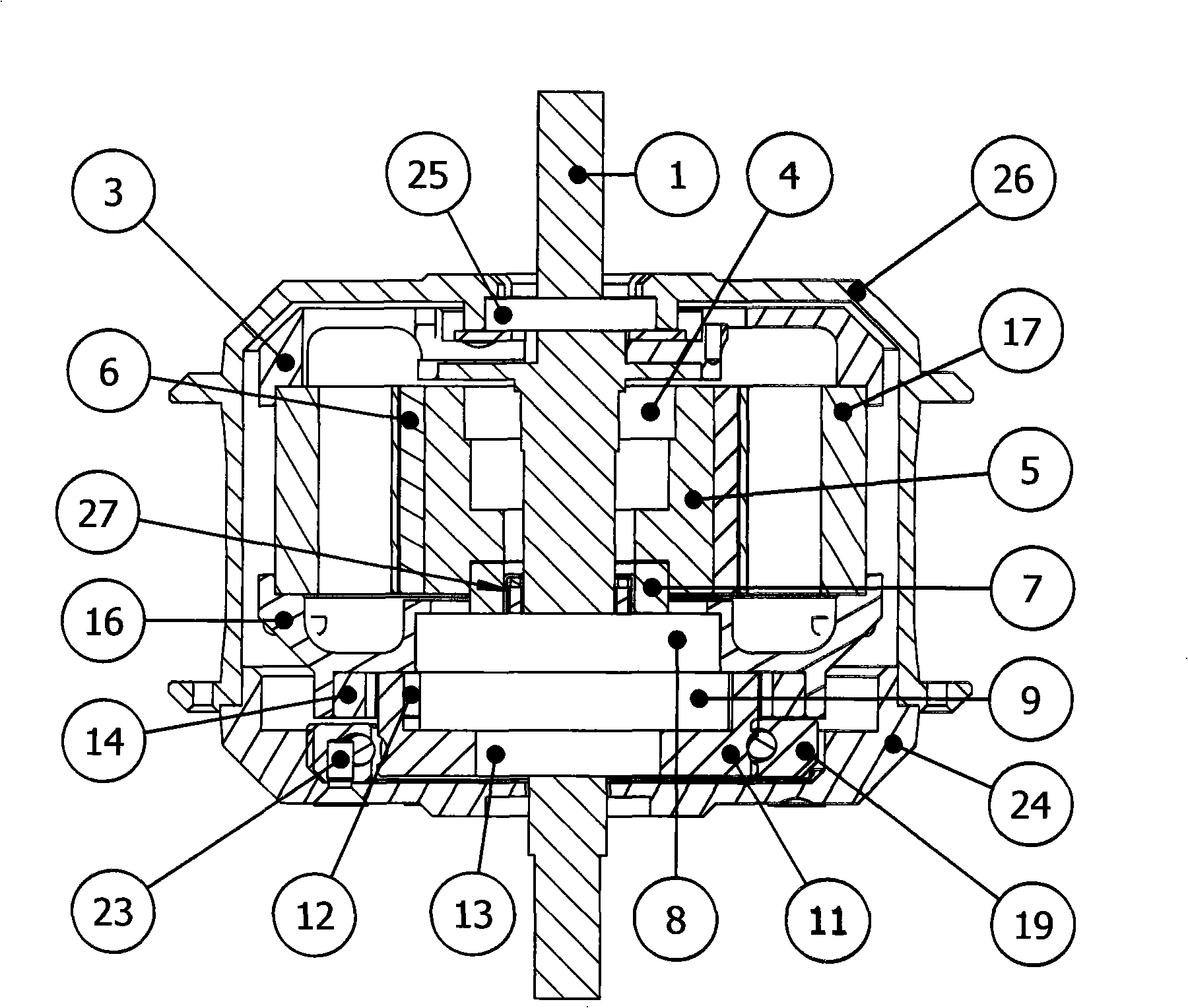

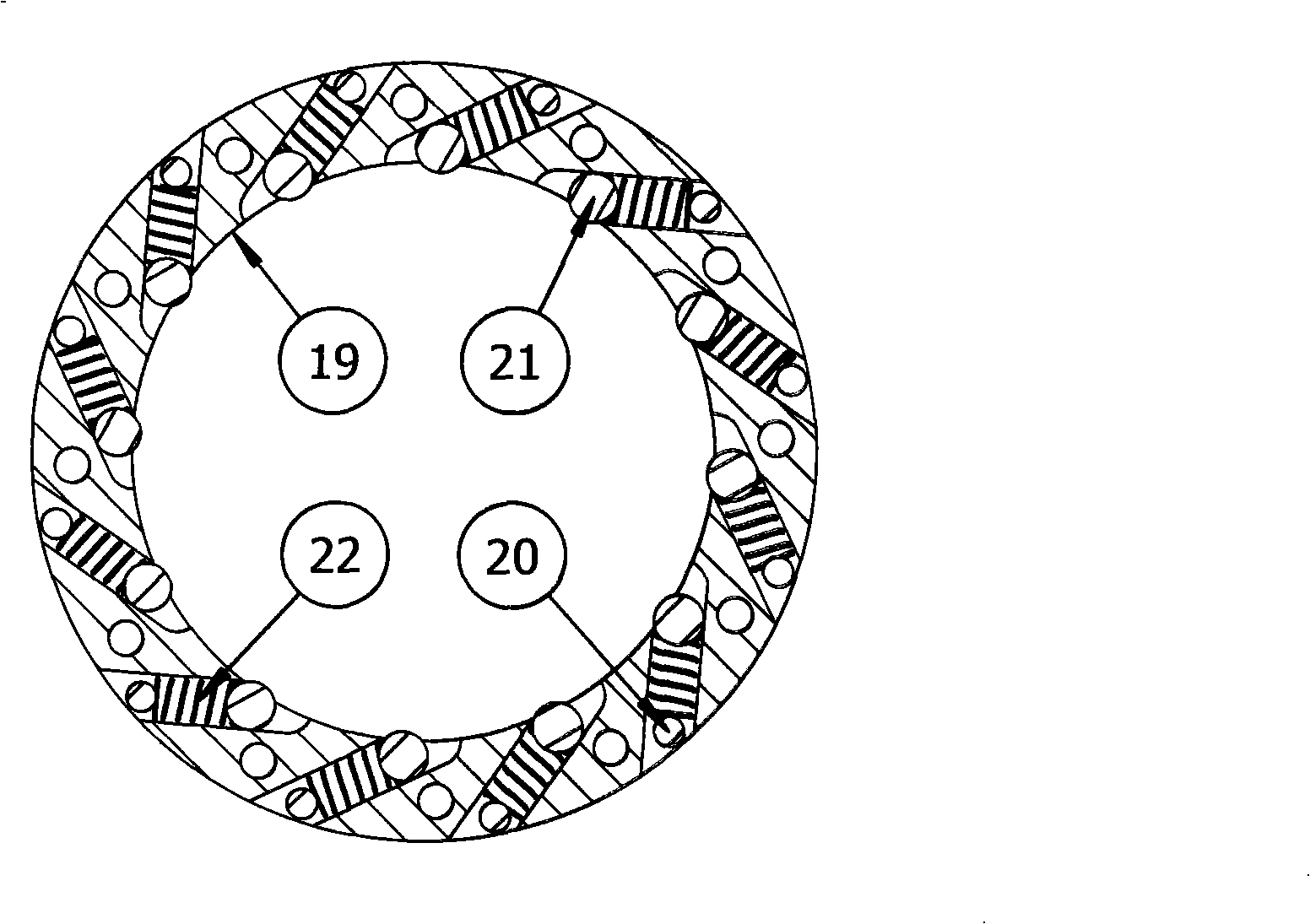

[0021] Depend on figure 1 Assemble the parts shown in the figure 2 The overall hub motor shown in the figure: connect the motor central shaft (1) and the left end cover of the stator (3) with the central shaft screw (2); connect the rotor (5) with the magnetic tile (6) through the rotor bearing (4) Assemble it into the central shaft (1) of the motor; press the supporting bearing (8) and the center wheel (14) into the right end cover (16) of the stator respectively, and fix the center wheel (14) with the fixed pin (15); The iron core stator (17) is inserted into the rotor (5), and the iron core stator (17) is clamped by the long screw (18) through the stator left end cover (3) and the stator right end cover (16); the inner hole of the eccentric shaft (7) and Needle roller bearings (27) are installed between the middle shafts (1) of the motor, and the eccentric shaft (7) equipped with the shock wheel (9) is installed and passed through the supporting bearing (8), and the rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com