Flux switching type axial magnetic field permanent magnet brushless motor

A permanent magnet brushless motor, axial magnetic field technology, applied in motors, electromechanical devices, electric vehicles, etc., can solve the problems of increasing the complexity of the rotor structure, irreversible demagnetization of permanent magnets, reducing the power density of the motor, etc. Responsive performance, small axial dimension, effect of improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

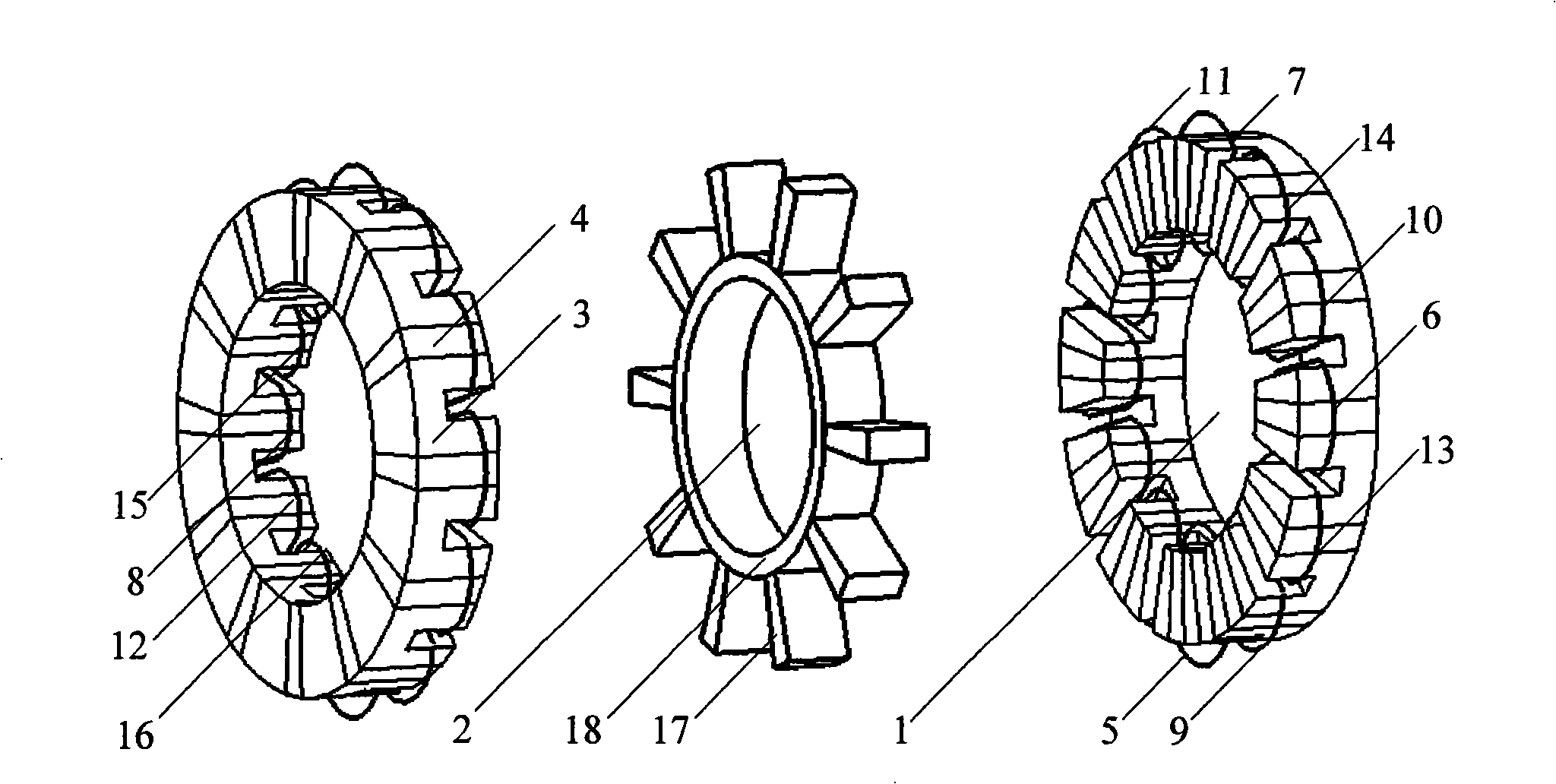

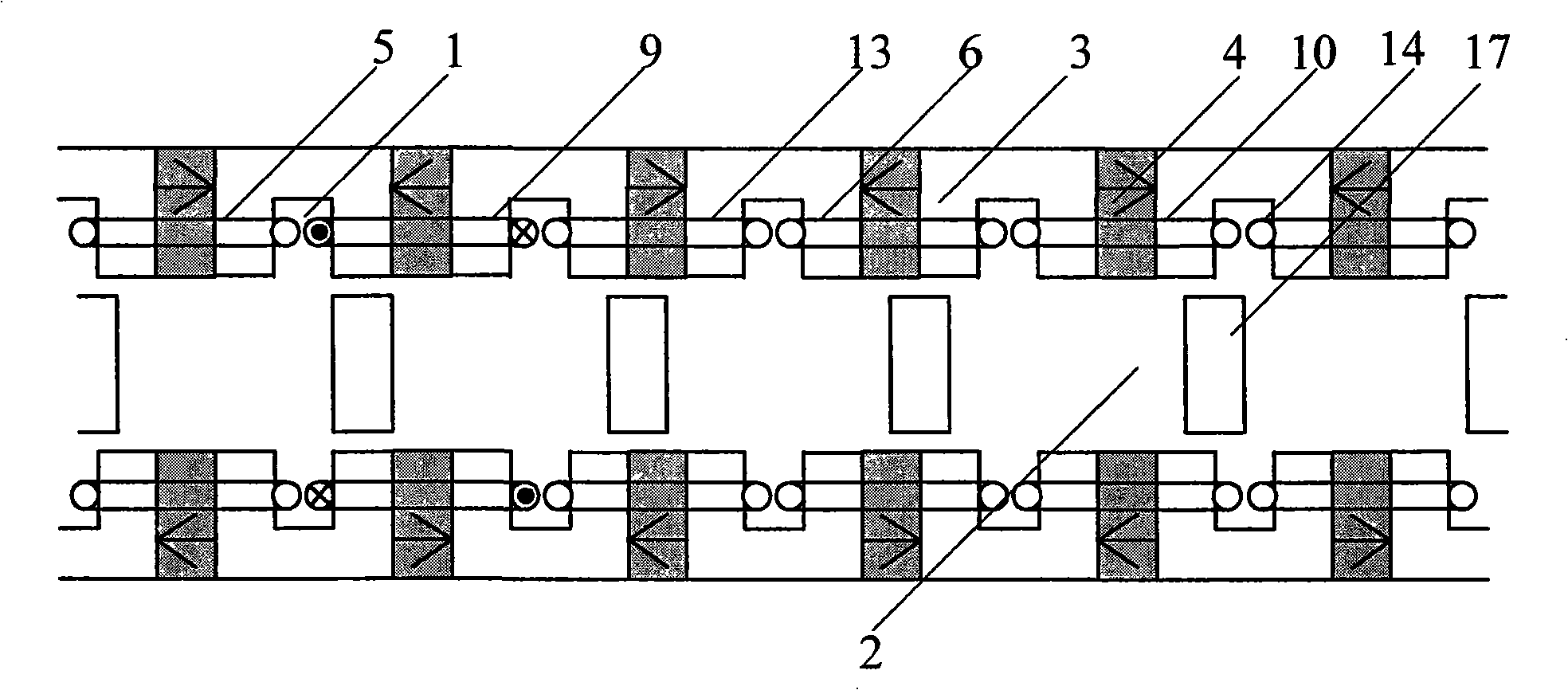

[0011] The motor consists of 6 U-shaped stator cores 3 and 6 permanent magnets 4. The stator 1 and 5 rotor poles 17 are combined into a basic motor with a 6 / 5 structure. The stator 1 and rotor poles 17 of the basic motor are integer multiples. By extension, a motor with a structure of 6a / 5a can be obtained, where a is a positive integer.

[0012] Such as figure 1 As shown, the flux-switching axial field permanent magnet brushless motor is a double-air-gap permanent magnet motor composed of two stators 1 and a rotor 2. The stator 1 and the rotor 2 are coaxially installed, and the rotor 2 is sandwiched between two There is an air gap of a certain thickness between the stators 1 and between the rotor 2 and the stator 1 . The structures of the two stators 1 are exactly the same, and they are symmetrical about the rotor 2; each stator 1 is composed of 12 U-shaped stator cores 3, 12 sector-shaped permanent magnets 4 and 12 concentrated windings 5, and the U-shaped stator core 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com