Circulation cold air apparatus for high voltage frequency conversion equipment

A high-voltage frequency conversion and circulating cold air technology, which is applied in output power conversion devices, cooling/ventilation of substation/switchgear, transformer/inductor cooling, etc. , inconvenient operation and other problems, to achieve the effect of low cost of use and maintenance, good promotion and application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

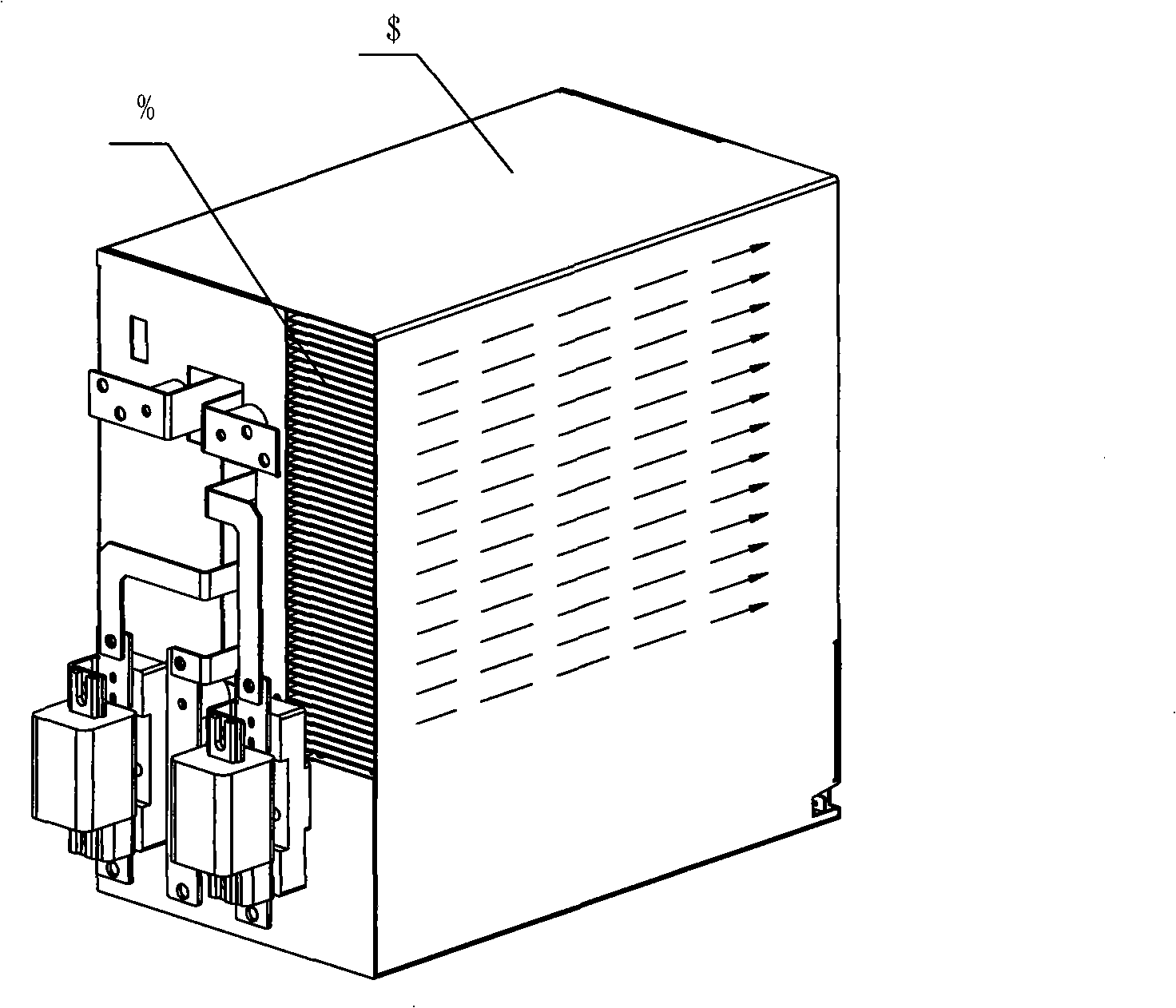

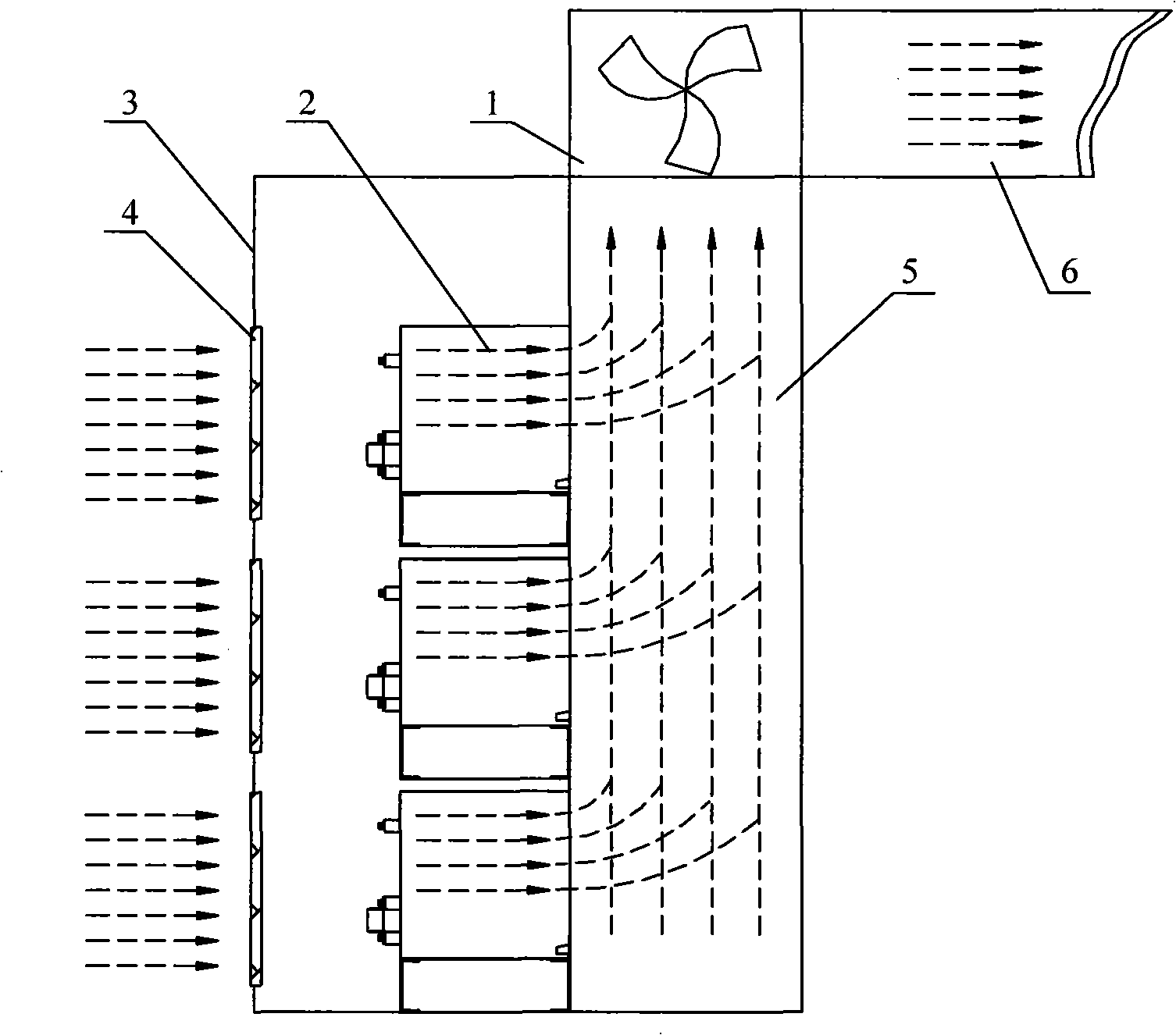

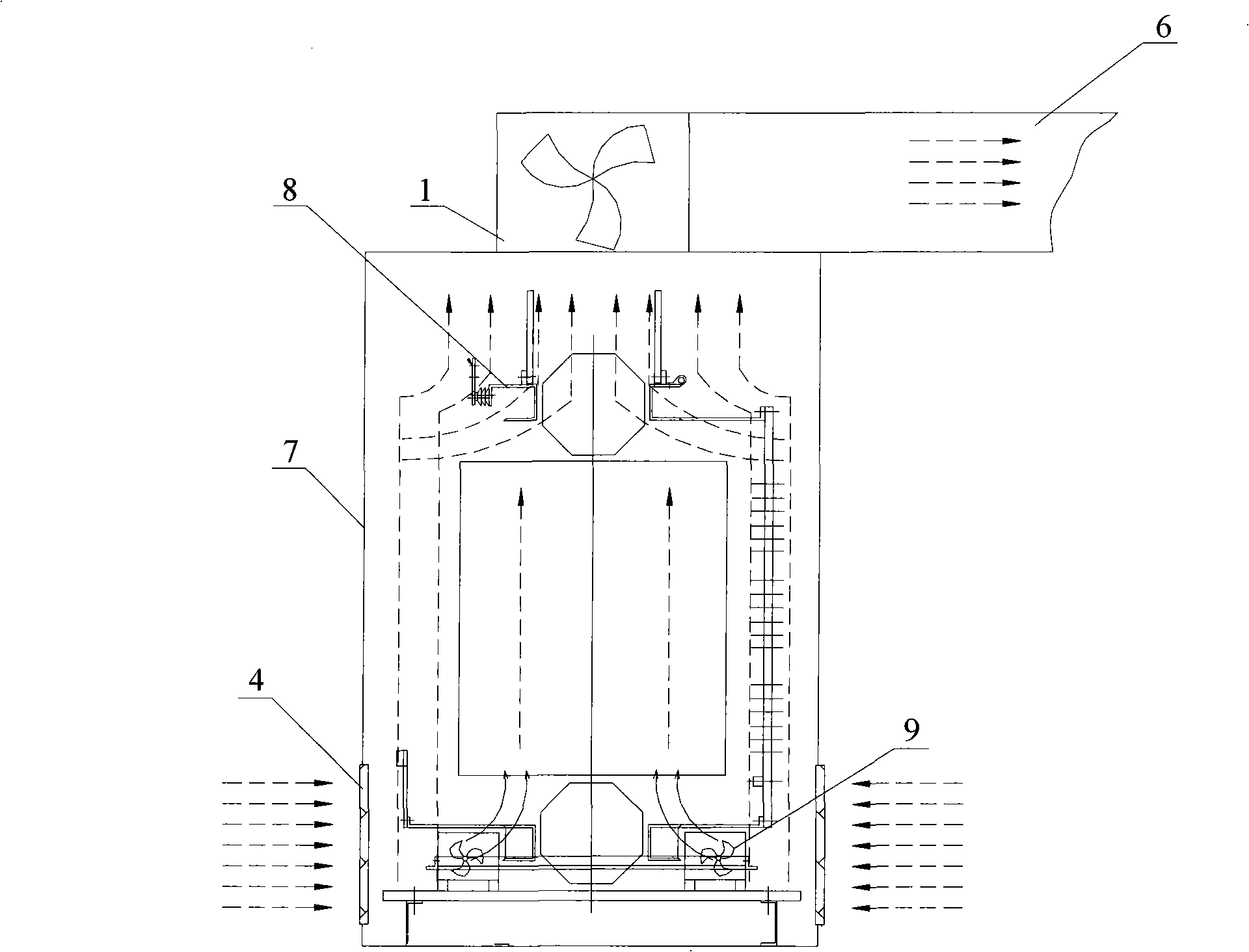

[0029] see Figure 4, to introduce an embodiment of the present invention-the structural composition of the circulating cold air device for the high-voltage frequency converter unit cabinet. The device includes four parts: the high-voltage frequency converter unit cabinet 3 that needs to be cooled for the heating components in the cabinet, and the heat exchange cabinet 12 that isolates and cools the hot air through the cold water in the disk-shaped pipeline. The hot air discharged from the high-voltage inverter unit cabinet is sent to the air inlet connection channel 10 of the air inlet of the heat exchange cabinet, and the cold air discharged from the heat exchange cabinet is sent to the air outlet connection channel 11 of the air inlet of the high-voltage invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com