Error correcting device of band type filter press

A technology of belt filter press and deviation correction device, which is applied in the field of deviation correction device, can solve the problems of high energy consumption and large gas consumption, and achieve the effects of low energy consumption, scientific control and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further elaborated below through the embodiments in conjunction with the accompanying drawings.

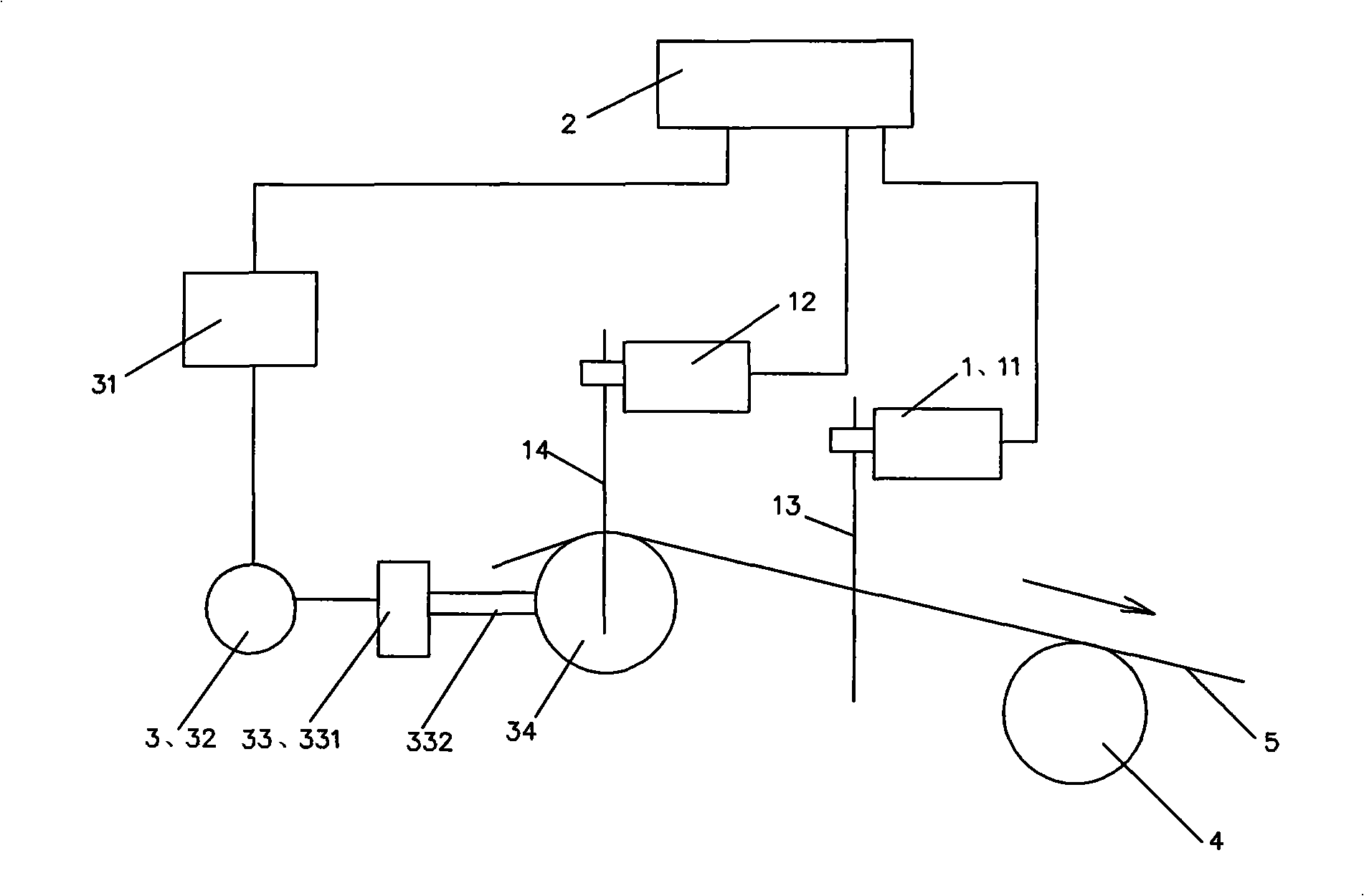

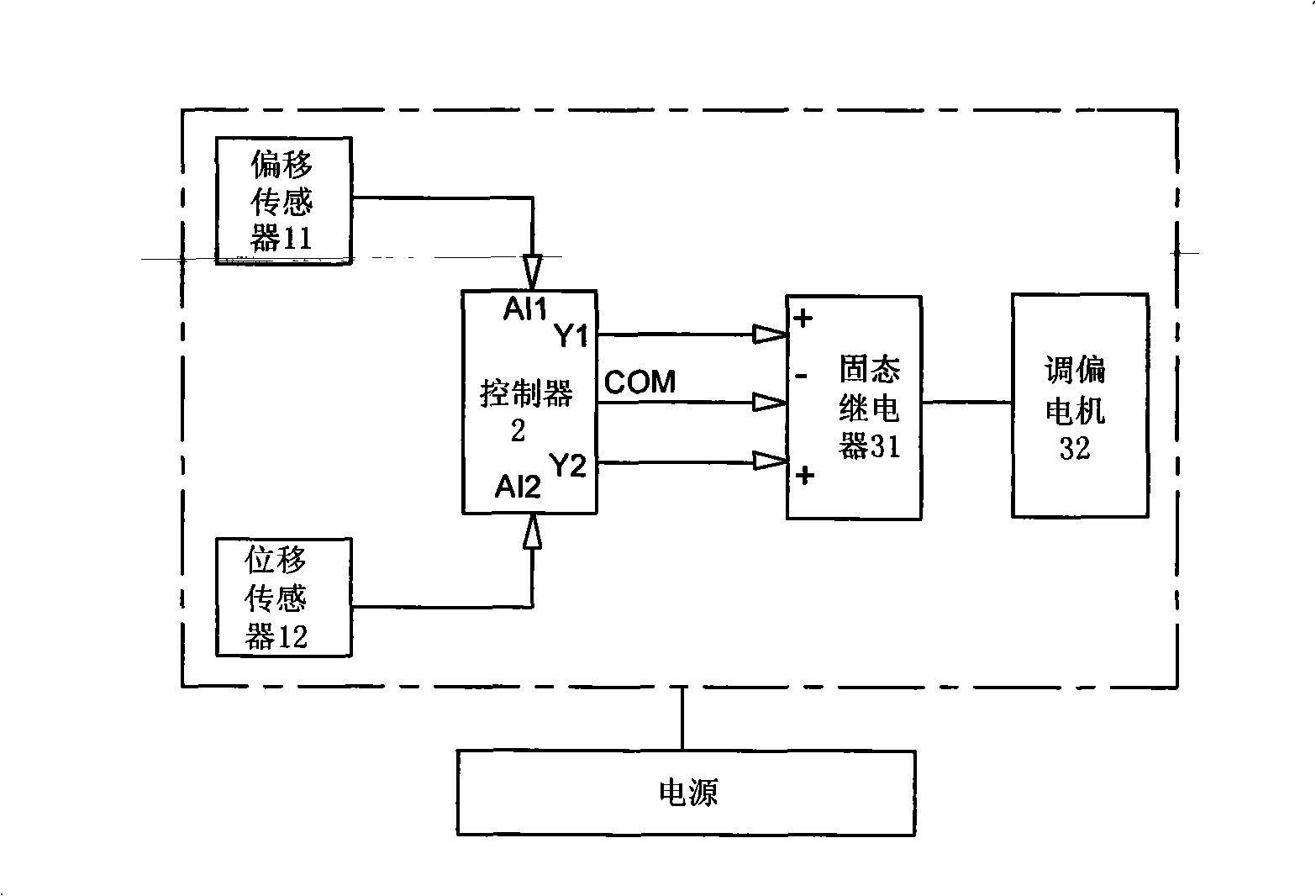

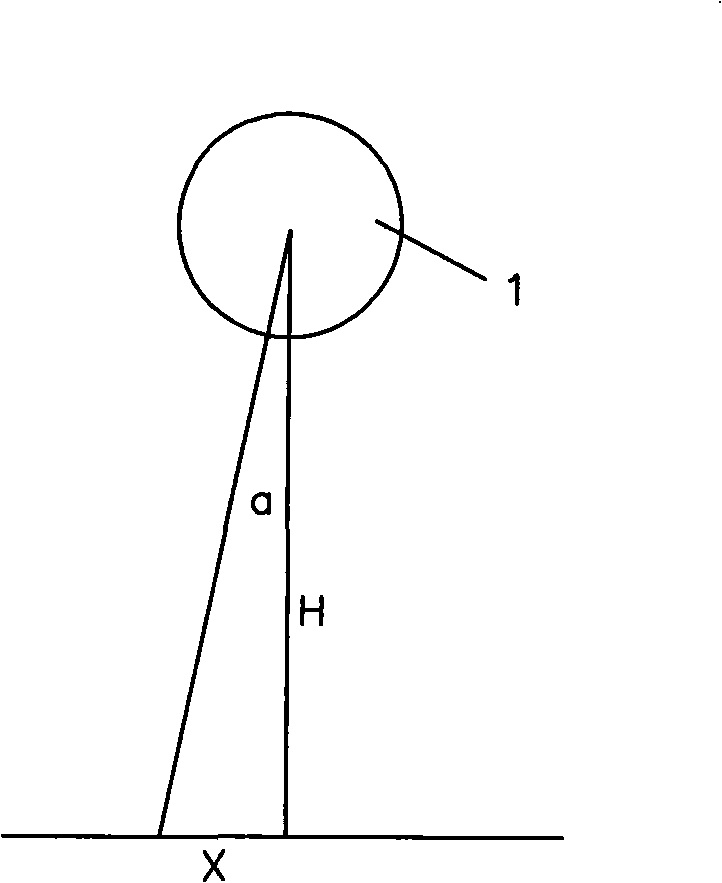

[0013] Example structure see figure 1 , figure 2 , the deviation correcting device of the belt filter press, including a sensor 1, a controller 2 and an execution component 3. The sensor 1 includes an offset sensor 11 and a displacement sensor 12 ; the execution unit 3 includes a motor steering controller, a deviation adjustment motor 32 , a transmission mechanism 33 and a deviation correction roller 34 . The deviation sensor 11 and the displacement sensor 12 are respectively installed directly above the standard position of the filter belt 5 and the deviation correction roller 34, the deviation correction roller 24 is installed close to the filter belt 5, the deviation adjustment motor 32 is connected to the motor steering controller, and the two ends of the transmission mechanism are respectively It is connected with the deviation adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com