Method for bionically catalyzing and oxidizing thiophen compounds

A technology of oxygen oxidation and biomimetic catalysis, applied in the fields of hydrocarbons, organic chemistry, purification/separation/stabilization of organic compounds, etc., can solve the problems of high consumption, high cost, unsatisfactory DBT, etc. The effect of low reaction pressure and non-corrosive environment

Inactive Publication Date: 2010-12-22

DALIAN UNIV OF TECH

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This study is good for BTs, not ideal for difficult DBT, and most of the DBT remains after the reaction

However, this type of reaction needs to consume a large amount of co-oxidants such as aldehydes, and the cost is relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

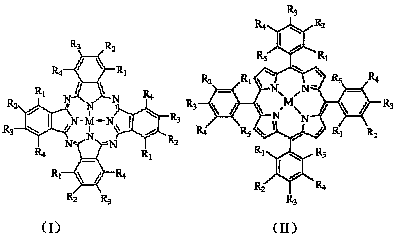

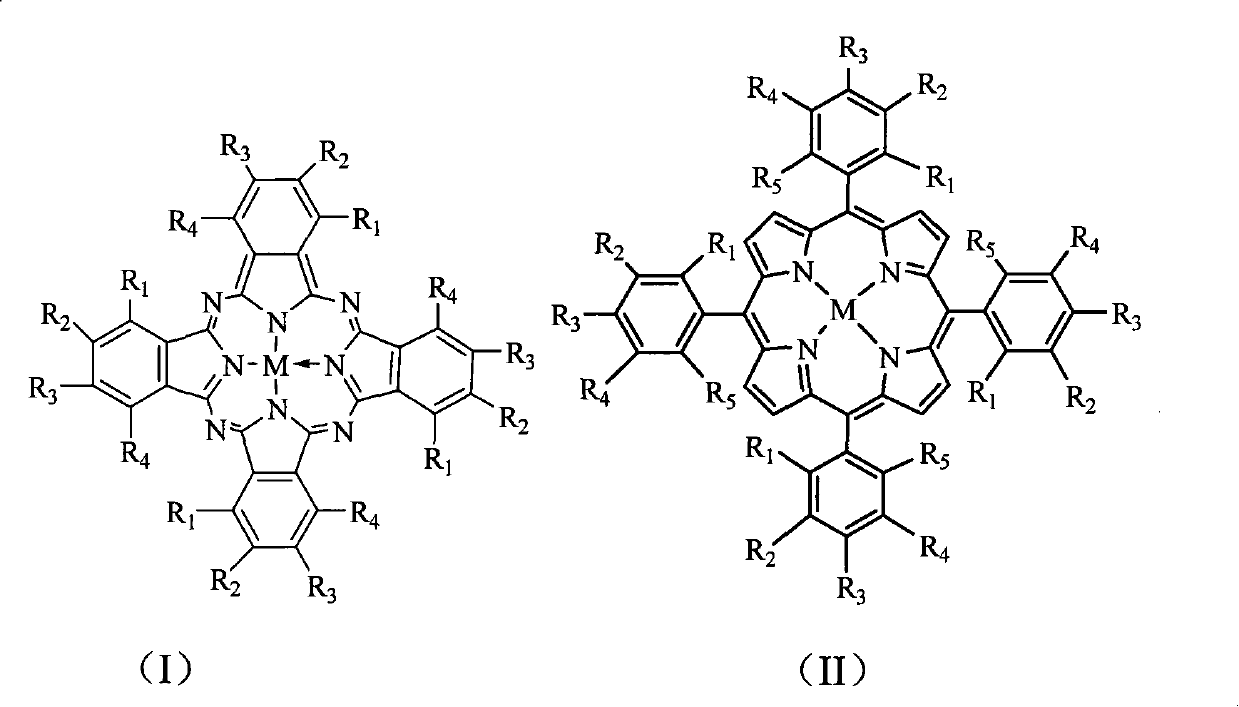

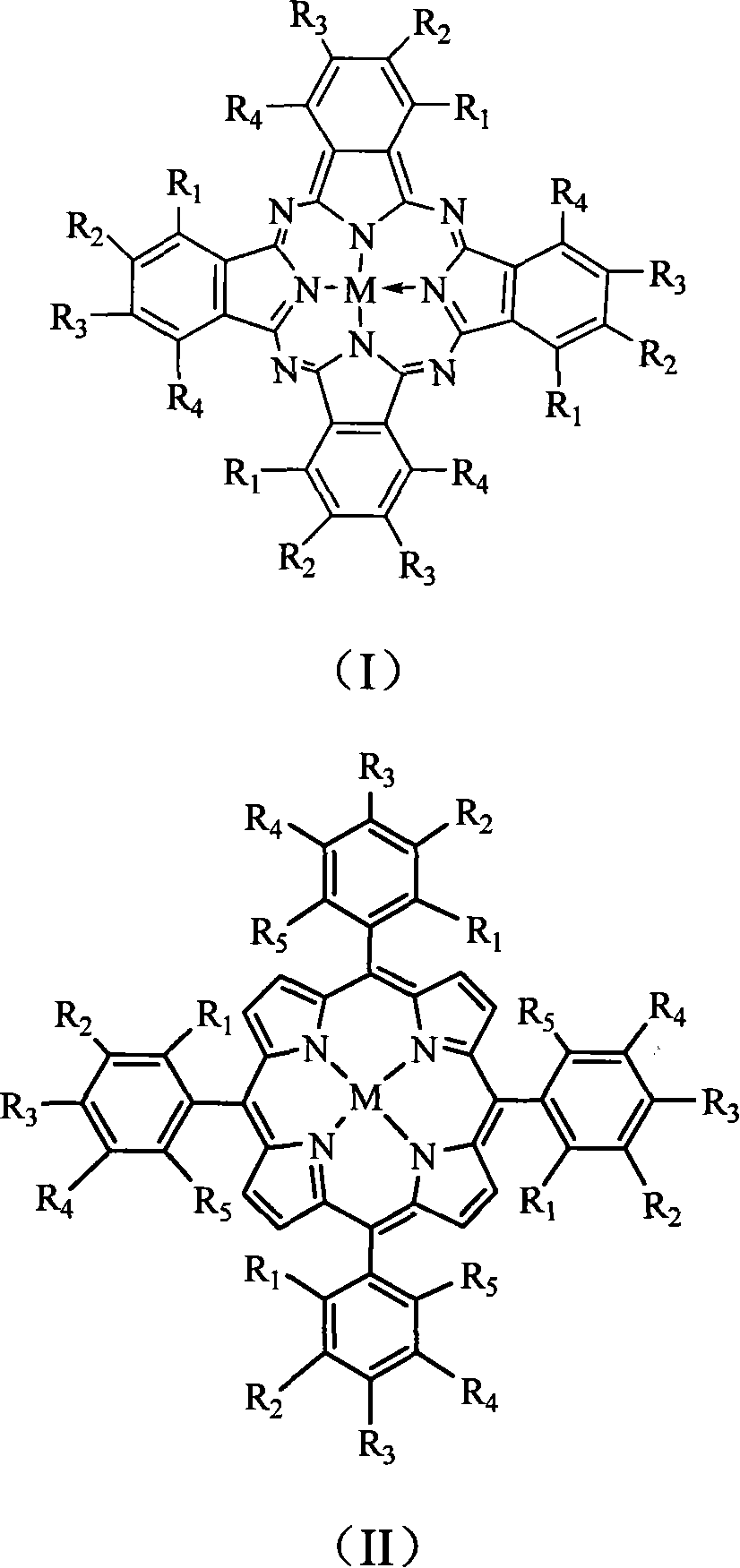

The invention discloses a biomimetic catalytic oxidation method of thiophene compound, characterized by the structure of the biomimetic catalyst of formula I and formula II, wherein, M is Fe, Co or Mn; R1 is NO2, NH2, Cl, F, SOH3 or H; R2 is NO2, NH2, Cl, F, SOH3 or H; R3 is NO2, NH2, Cl, F, SOH3 or H, R4 is NO2, NH2, Cl, F, SOH3 or H; and R5 is NO2, NH2, Cl, F, SOH3 or H. Due to the application of metal phthalocyanine compound and metal porphyrins as the catalyst, the invention has the benefits of transferring and activating oxygen molecule, and catalytic oxidating organics with high selectivity under a mild condition. The reaction system of the invention has low use level of the catalyst, reduced cost, low reaction temperature and reaction pressure, no oil corrosion, is friendly to environment, can be recycled, as well as can achieve deep desulfurization of oil product, without requiring any cooxidation agent.

Description

Technical field The invention belongs to the technical field of catalytic oxidation desulfurization, and relates to a method for biomimetic catalytic oxygen oxidation of thiophene compounds. Background technique Hydrodesulfurization is a relatively mature process at present, which can easily remove mercaptans and sulfides from oil products. However, it is difficult to hydrogenate dibenzothiophene, especially the dibenzothiophene substituted at the 4th or 4th and 6th positions. The reaction conditions of oxidative desulfurization are mild, do not consume hydrogen, and can effectively remove dibenzothiophene and alkyl-substituted dibenzothiophene series sulfides. The process investment and operating cost are lower, and the operating conditions are easier than hydrodesulfurization, and the application prospects broad. The key step in oxidative desulfurization is the oxidation reaction of sulfide. The early use of oxygen for oxidative desulfurization technology was the oxidation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J31/22B01J31/28B01J31/32C07C7/173C07C13/50C07B63/02

Inventor 周新锐张珊珊李娟

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com