Intermittent screw thread type reaction injection mixing element

A technology of injection mixing and thread type, which is applied in the field of mixing components, can solve the problems of high equipment investment and operating costs, and easy breakage of components, and achieve the effects of low operating costs, improved service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

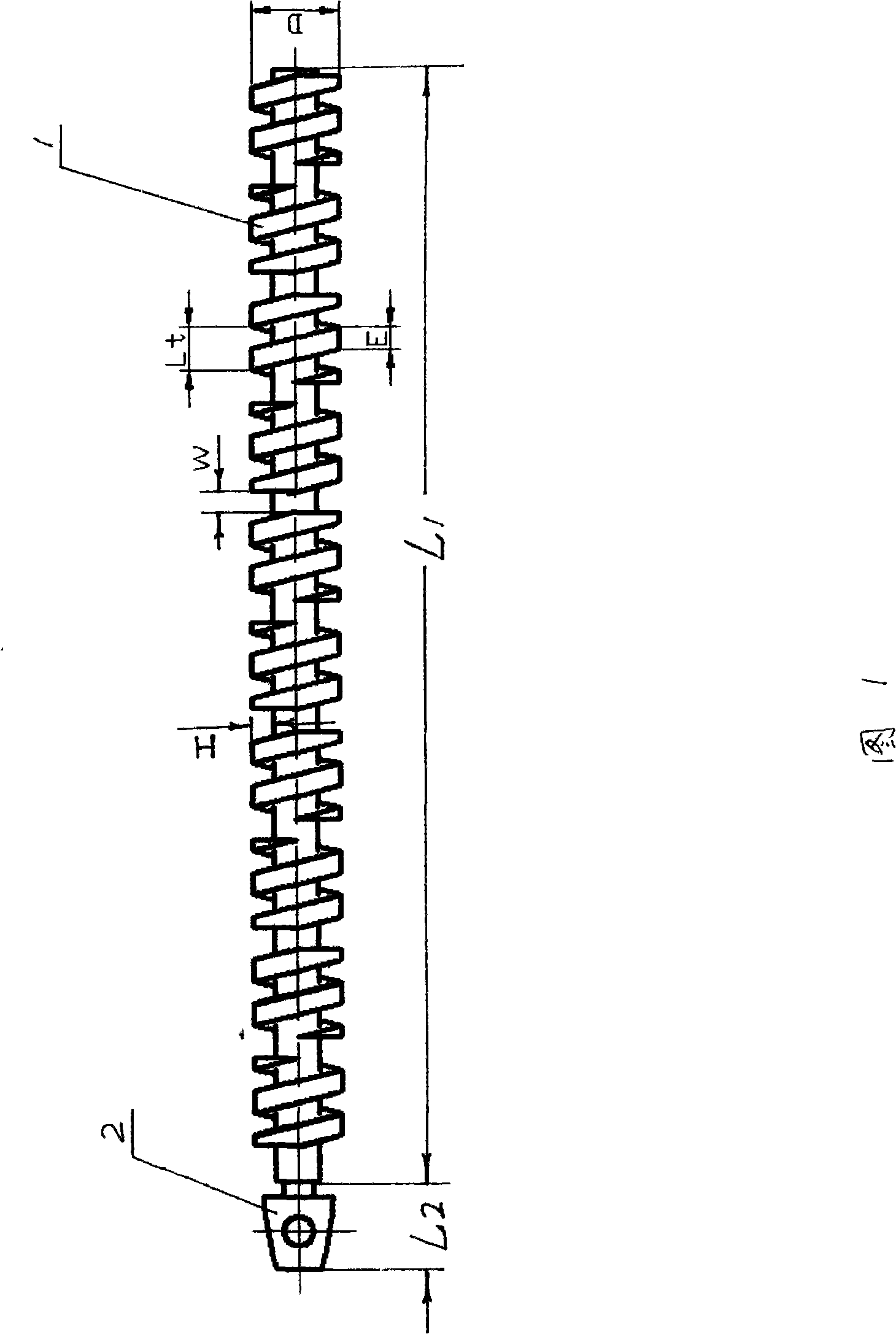

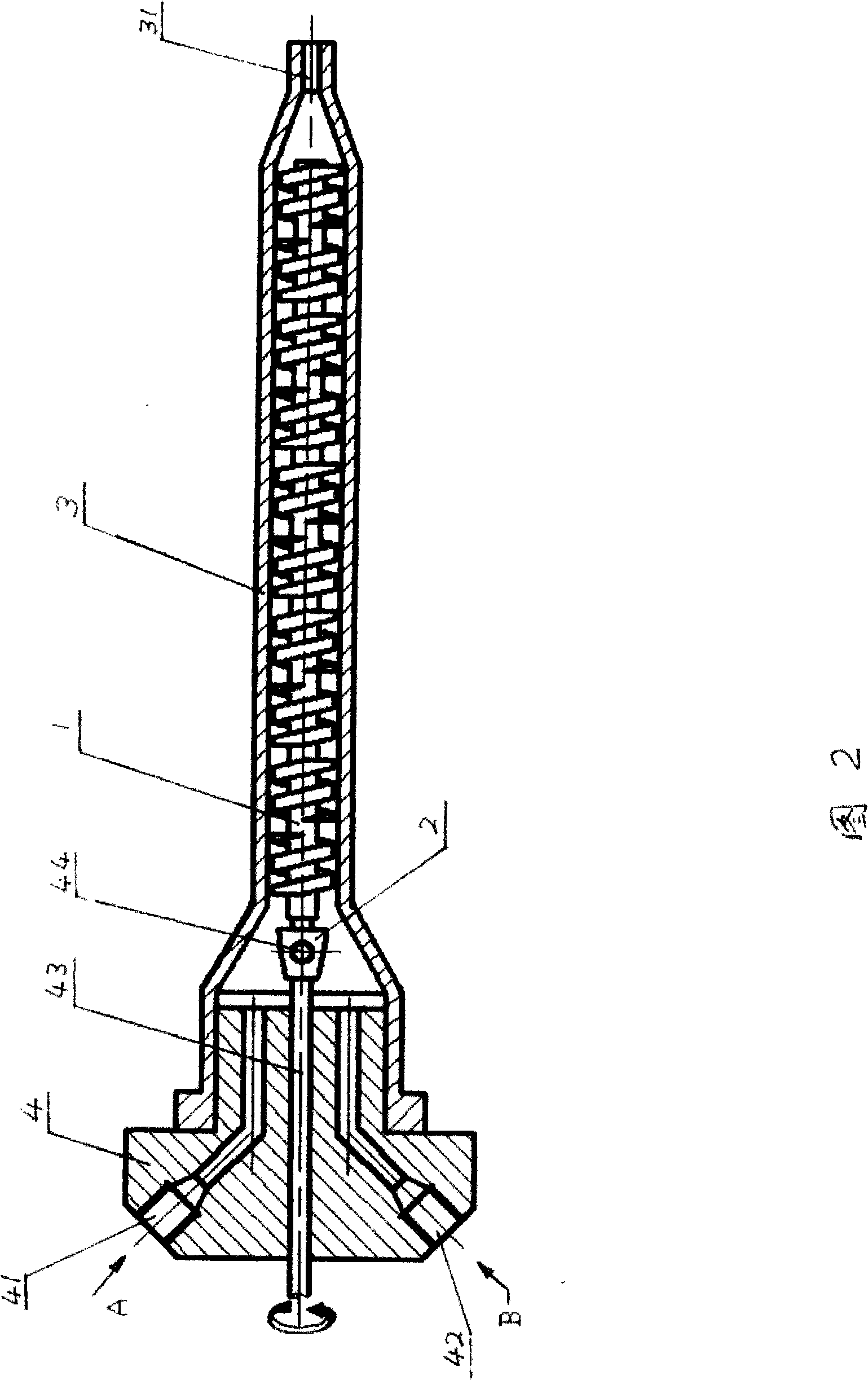

[0015] As shown in Figure 1, an intermittent thread type reaction injection mixing element is composed of an interrupted thread type working section 1 and a driving connection section 2, wherein: the interrupted thread type working section 1 is a rectangular threaded section made of metal materials , its structural parameters are length L1, diameter D, screw pitch Lt, screw edge width E, screw groove depth H, and a discontinuous groove with discontinuous width W is processed every two pitches, and discontinuous groove depth is also is the depth of the screw groove, according to different needs, according to the predetermined structural parameters, the intermittent screw type reaction injection mixing element is turned; the length of the driving connection section 2 is L2, and the drive shaft of the mixing element with the reaction injection molding equipment is produced on its length L2 Compatible connected structure.

[0016] Referring to a specific embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com