Production method of fine denier hollow polyester staple fiber

A technology of polyester staple fiber and production method, which is applied in the directions of staple fiber formation, hollow filament manufacturing, fiber chemical characteristics, etc. Stable hand feel and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

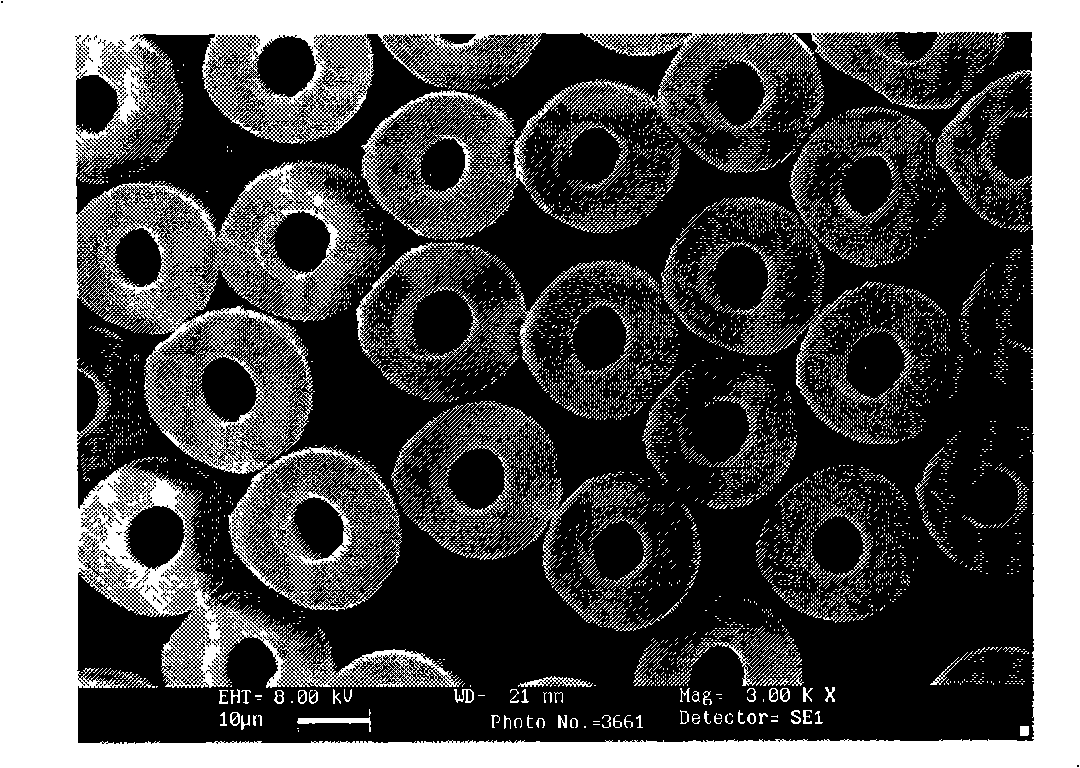

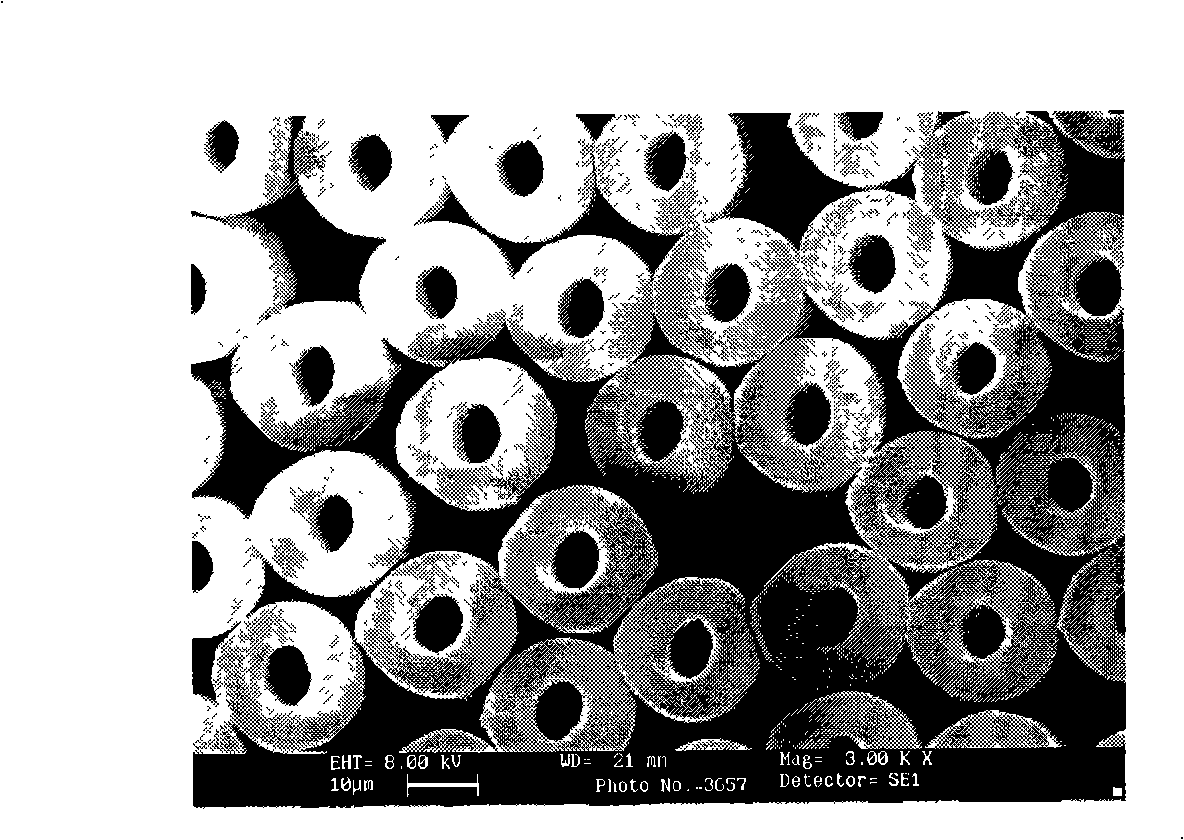

[0019] The invention adopts the innovatively designed fine-denier hollow special spinneret, and on the conventional polyester staple fiber production line, through the optimization and adjustment of the production process, produces the fine-denier hollow polyester staple fiber with a specification of 0.8dt~1.5dt, which meets the market demand. Filled in the gaps at home and abroad.

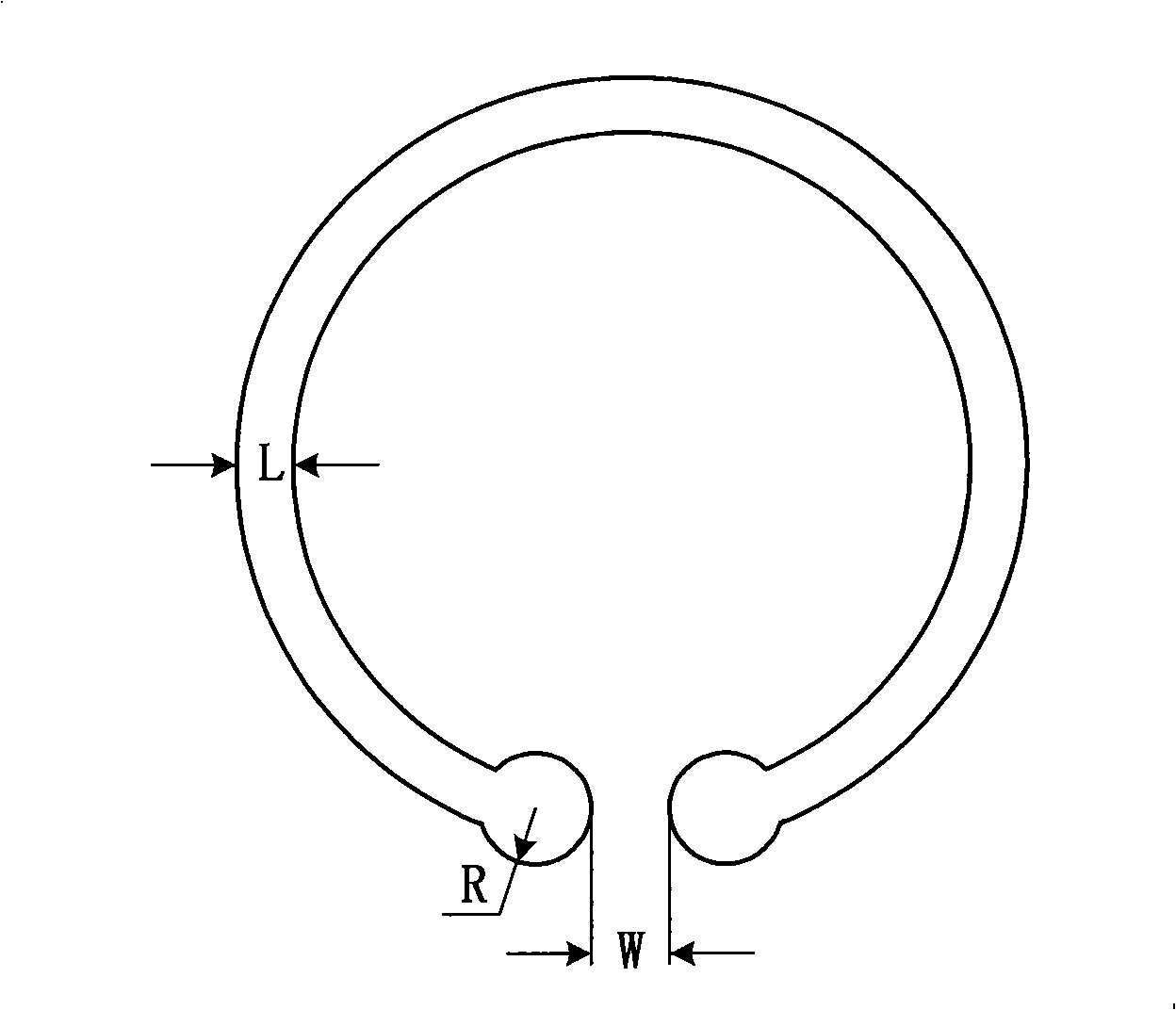

[0020] First of all, the present invention adopts an innovatively designed spinneret, and the spinneret hole is in the shape of a single-opening "C" ring, such as figure 1 As shown, while effectively improving the closing success rate of the cross-section of the fiber, the fiber is guaranteed to have a high degree of hollowness.

[0021] Specifically, the slit width L of the spinneret "C"-shaped ring, the opening degree W, and the shape design of the two ends of the opening are the techniques for spinning round hollow polyester staple fibers with suitable hollowness and good closure rate. The ess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slit width | aaaaa | aaaaa |

| Opening | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com