Prime motor output torque balance control system

A technology of balanced control and output torque, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of small application range, complex structure and high cost of output torque adjustment technology, and achieve wide application range, simple structure and high performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

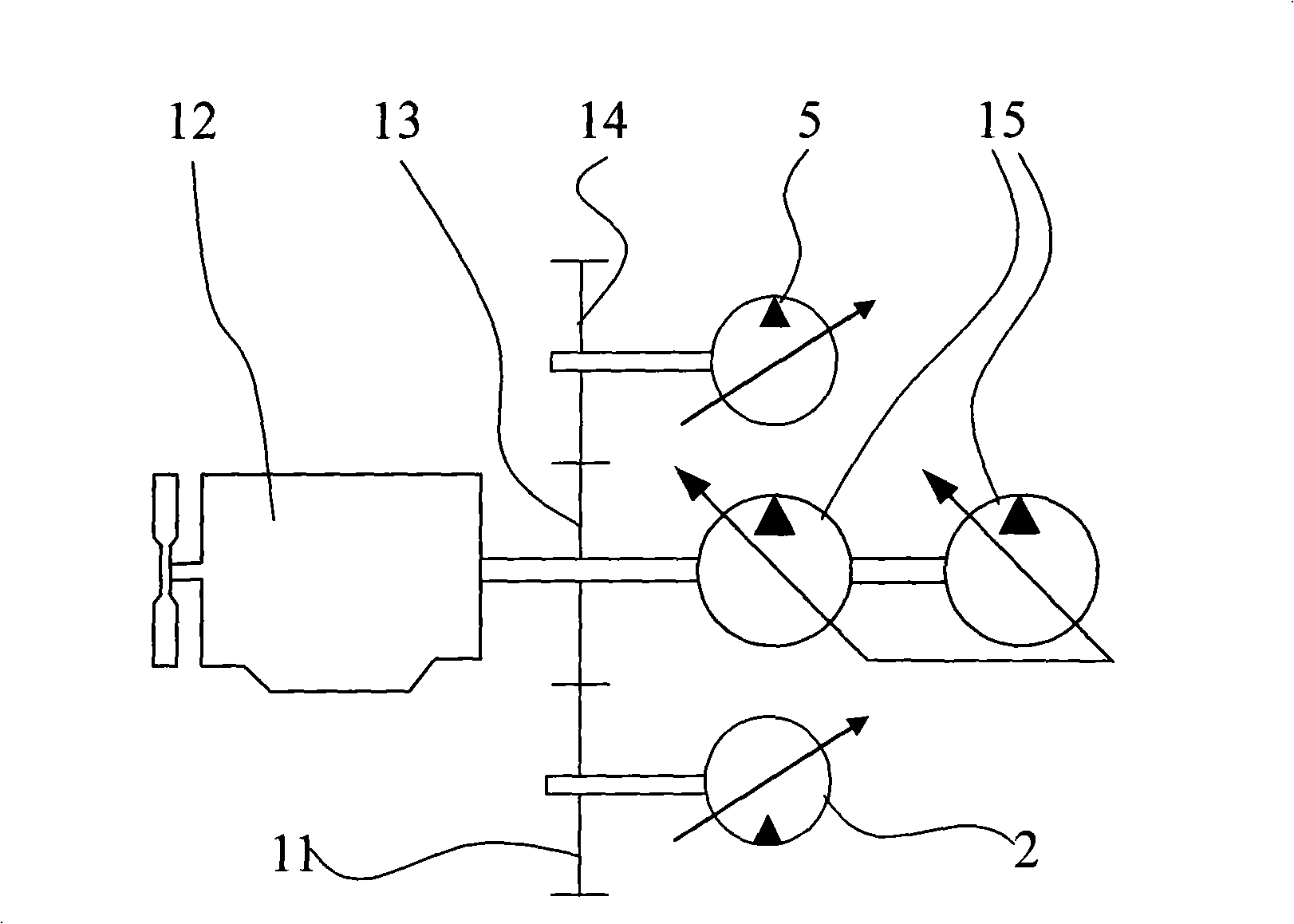

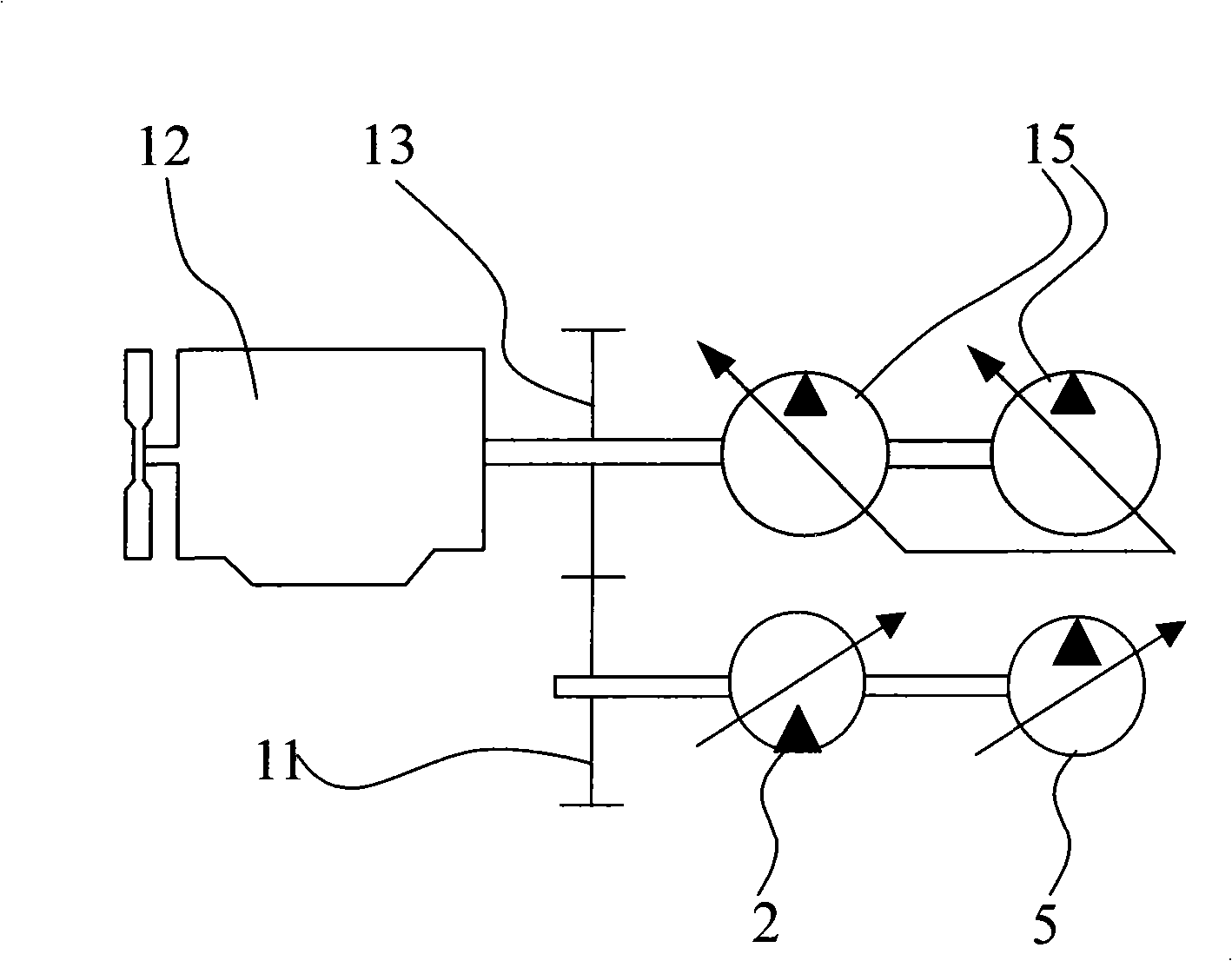

[0045] refer to figure 1 , Figure 14 , a prime mover output torque balance control system, the control system includes an energy storage pump 5, an accumulator 4, a power booster motor 2, transfer gears 11, 14 and a central gear 13 connected to the output shaft of an internal combustion engine 12, the energy storage The input shaft of the pump 5 is connected to the first transfer gear 14, the first transfer gear 14 meshes with the sun gear 13, the sun gear 13 is connected to the input shaft 15 of the main hydraulic pump, and the output shaft of the booster motor 2 is connected to the second Two transfer gears 11, the second transfer gear 11 meshes with the sun gear 13, the energy storage pump 5 is connected to the booster motor 2; the outlet of the energy storage pump 5 is connected to the The inlet and outlet of the accumulator 4, the first one-way valve 3 only allows hydraulic oil to flow from the outlet of the accumulator pump 5 to the inlet and outlet of the accumulator ...

Embodiment 2

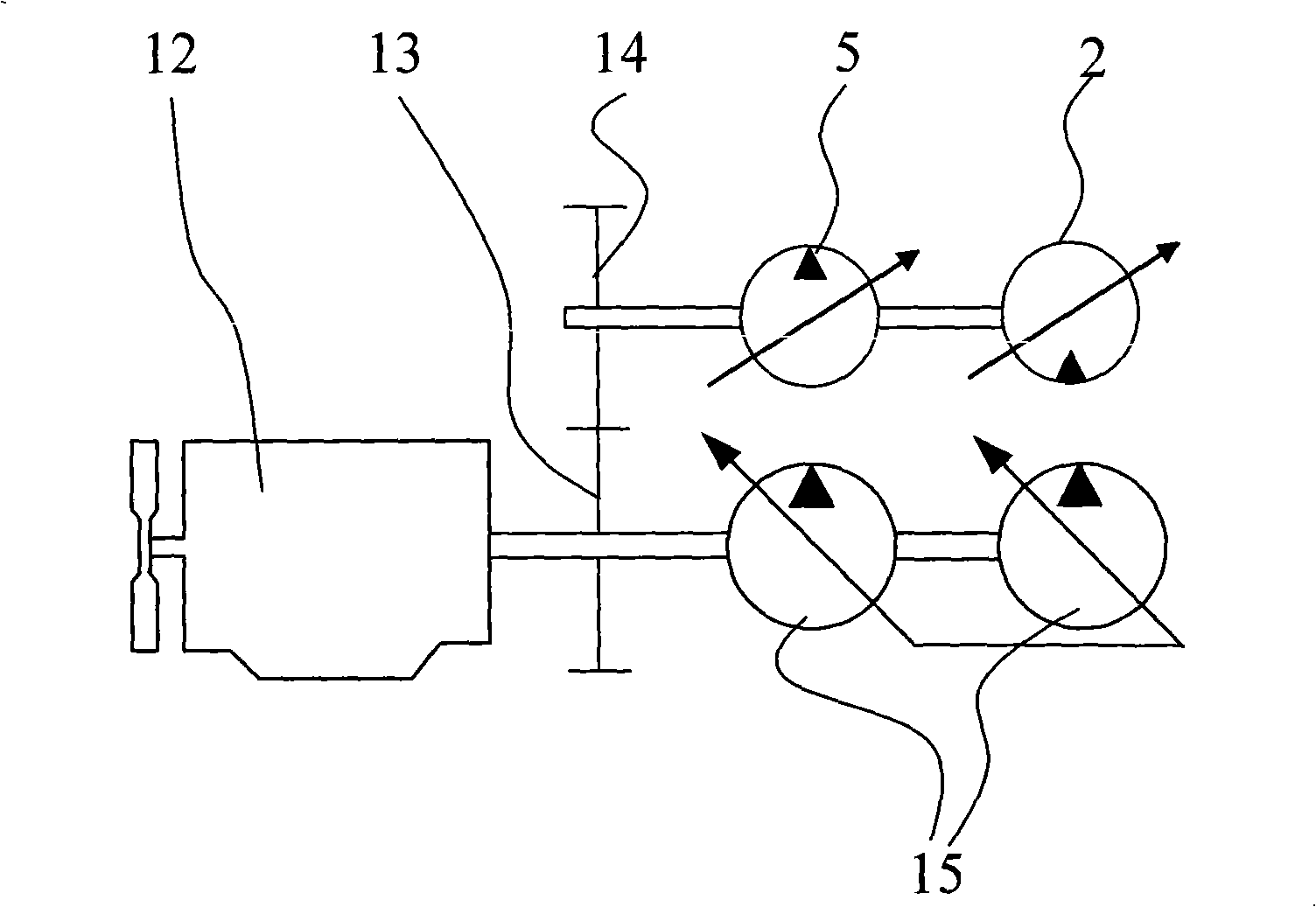

[0059] refer to Figure 1-13 , Figure 15 , Figure 16 In this embodiment, the inlet and outlet of the accumulator 4 are connected to the inlet of the booster motor 2 through the second controlled one-way valve 9, and the controlled one-way valve 9 prevents hydraulic oil from flowing from the accumulator 4 without a control signal. The entrance and exit to the entrance of the booster motor 2; the torque controller outputs the signal P according to the pilot pressure of the construction machinery i , when the pilot pressure signal is greater than the preset threshold value, a channel command signal P is sent to the second controlled one-way valve 9 i . , the accumulator 4 is equipped with a pressure sensor 6, the outlet of the accumulator pump 5 is also connected to the oil tank 8 through the first controlled one-way valve 10, and the controlled one-way valve 10 is under the condition of no control signal Prevent hydraulic oil from the outlet of the accumulator pump 5 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com