Vehicle mounted traveling type soil density sensor

A soil firmness and sensor technology, applied in the field of sensors for measuring soil firmness, can solve the problems of complex measuring mechanism, measurement error, inconvenient integration, etc., and achieve the effect of simplifying the measuring mechanism, improving the integration degree and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

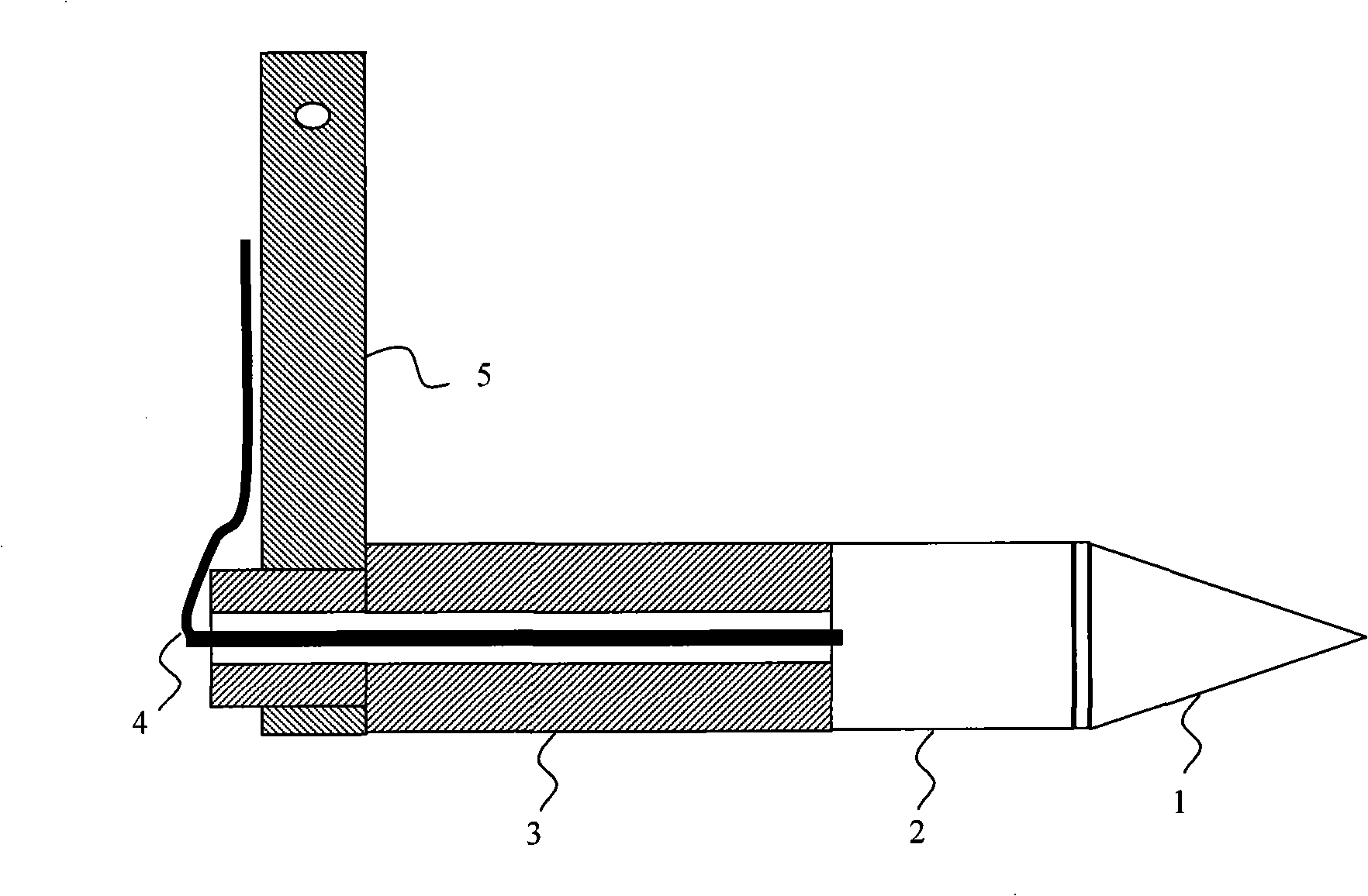

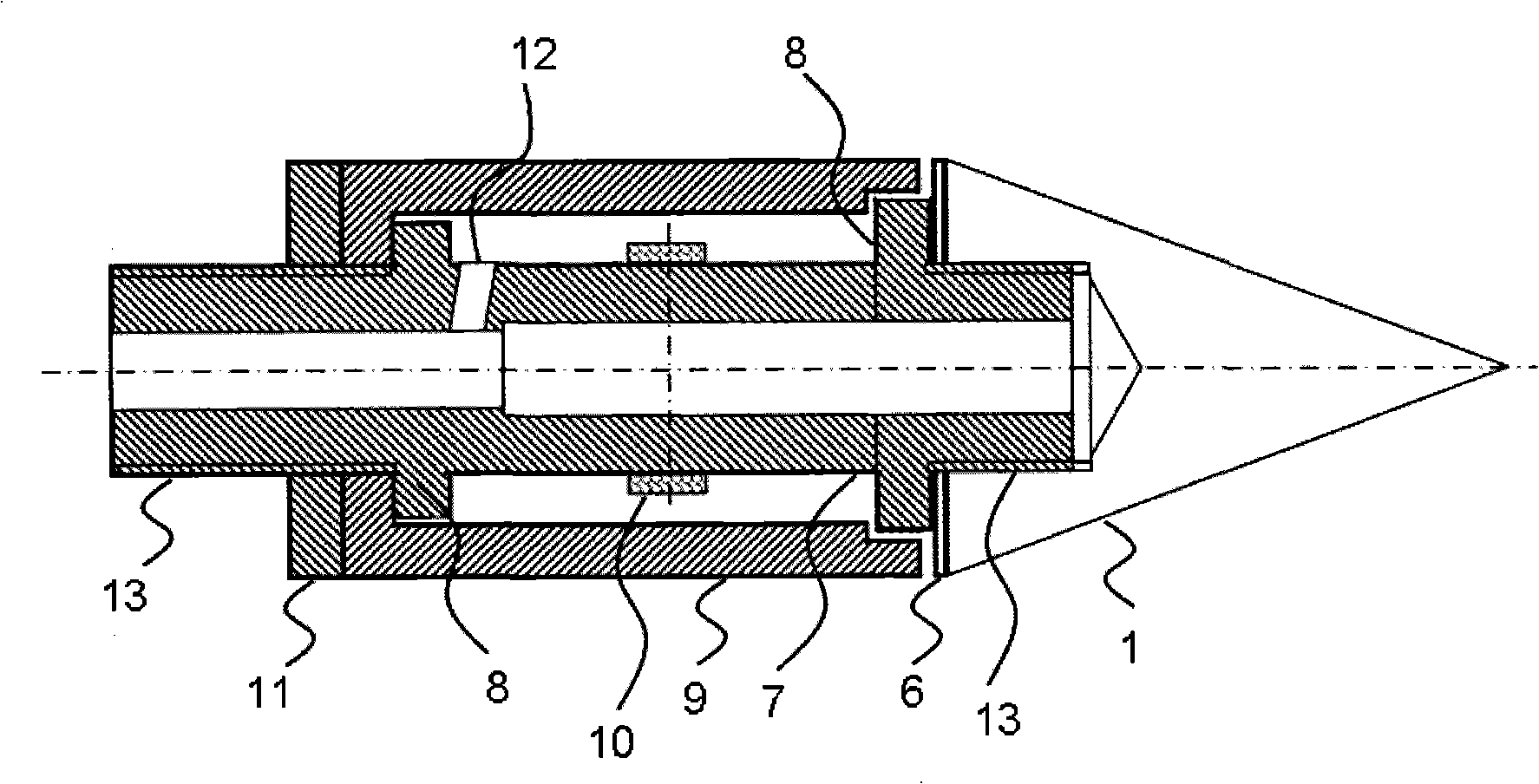

[0023] Such as figure 1 As shown, the cone head 1 can be the conical type recommended by the American Society of Agricultural Engineers (ASAE) standard, or it can be a pyramid type or other shapes; the micro pressure unit 2 is based on the strain gauge or piezoelectric principle, reflecting the soil resistance on the cone head , without being affected by soil friction and travel depth; on the one hand, the support rod 3 serves as the support point of the micro pressure unit 2, and can also be further combined with other soil parameter measurements, such as the measurement of parameters such as soil moisture, electrical conductivity and temperature; The lead wire of miniature pressure unit is drawn from the center hole of support rod 3; Connecting rod 5 realizes the connection of probe (conical head 1, miniature pressure unit 2 and support rod 3 collectively) and vehicle-mounted equipment, with respect to soil firmness sensor of the present invention In other words, as long as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com