Soil discharging control method of center drive mono-tube soil sucker

A technology of central transmission and control method, applied in separation methods, chemical instruments and methods, feed/discharge devices of sedimentation tanks, etc. and other problems to achieve the effect of reducing backflow, reducing energy consumption and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

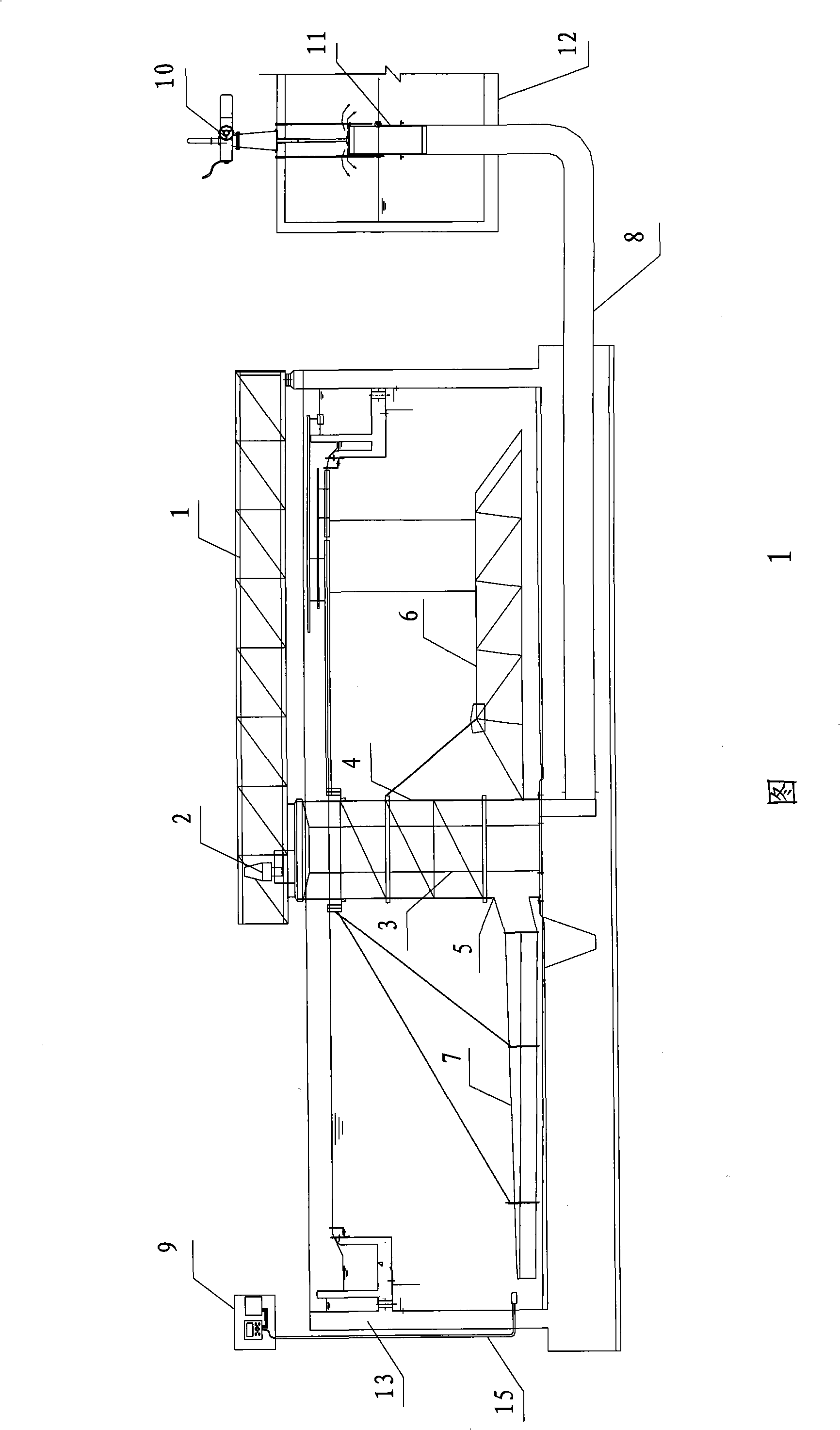

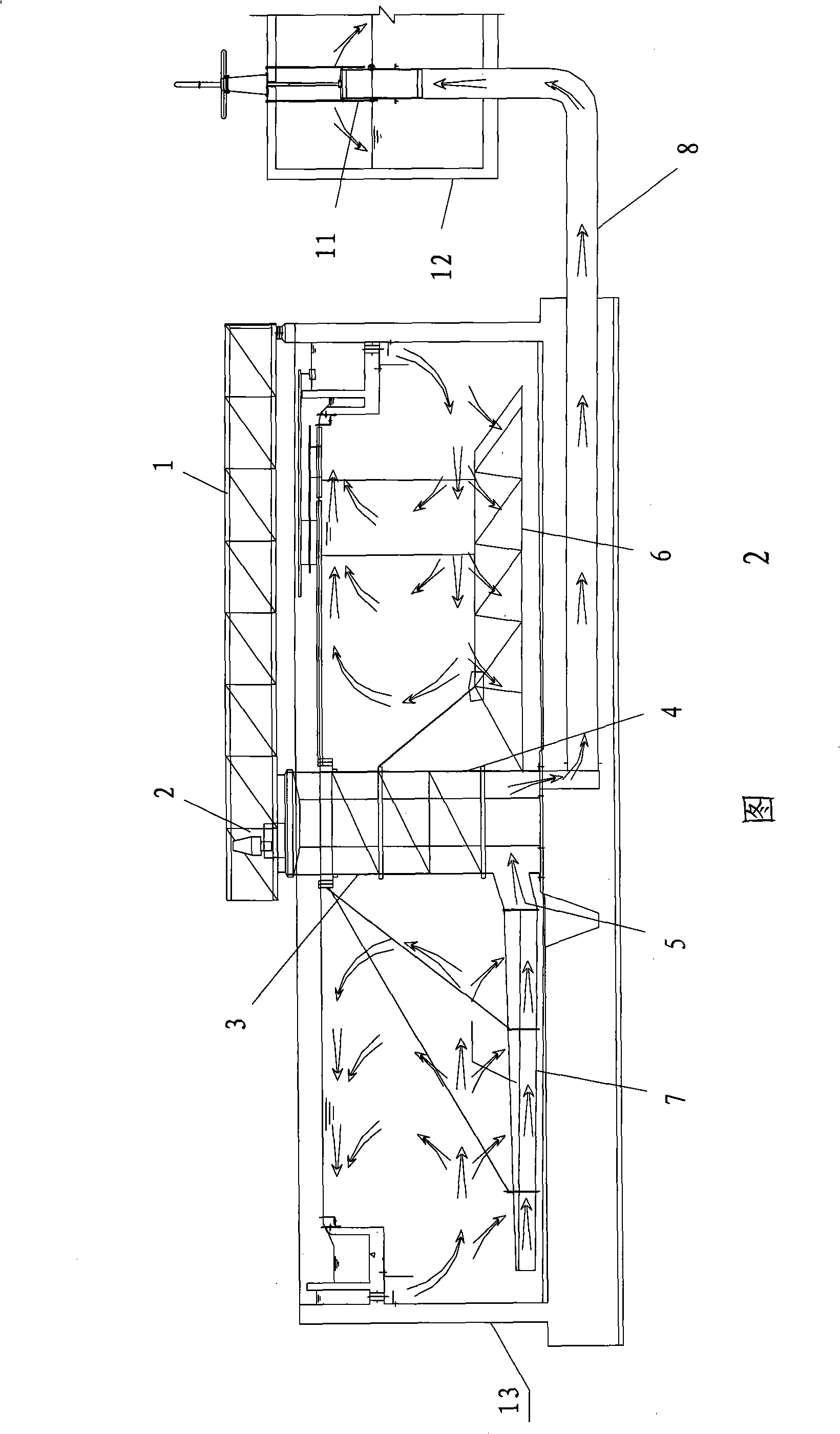

[0025] Referring to Fig. 1, it is a schematic structural view of a centrally driven single-pipe dredger of the present invention, the centrally driven single-pipe dredger is composed of a drive mechanism 2, a rotating cage 4, a mud collection tube 5, and a truss arranged at the sedimentation tank 13. 6. The mud suction pipe 7, the mud discharge pipe 8, the mud discharge valve 11, the electric actuator 10, the sludge concentration meter 15 and the controller 9 are composed, wherein the drive mechanism 2 is arranged on the top of the central column 3 in the middle of the sedimentation tank 13, and turns The cage 4 is set on the outer periphery of the center column 3, and the mud collection tube 5 is set outside the center column 3 at the bottom of the tumbler 4, and is connected to the suction pipe 7, and the inside is connected to the mud discharge pipe 8 through a fan-shaped well, and the mud discharge pipe 8 is connected to the The port of the mud discharge well 12 and the sed...

Embodiment 2

[0039] Referring to Fig. 4, it is a schematic structural view of another central drive single-pipe dredger of the present invention, and its structural difference from Embodiment 1 is that in this embodiment, the sludge concentration meter 15 is arranged in the mud discharge well 12 , collect the sludge concentration in the sludge discharge well 12 in real time, and transmit the sludge concentration signal to the controller 9, and the controller 9 controls the electric actuator 10 to adjust the opening degree of the sludge discharge valve 11 according to the state of the sludge concentration. The mud concentration signal is directly proportional to the relationship. The sludge concentration meter 15 can also be arranged in the sludge discharge pipe 8 which is also the sludge discharge channel, and the corresponding sludge discharge valve 11 can also be arranged on the sludge discharge pipe 8 .

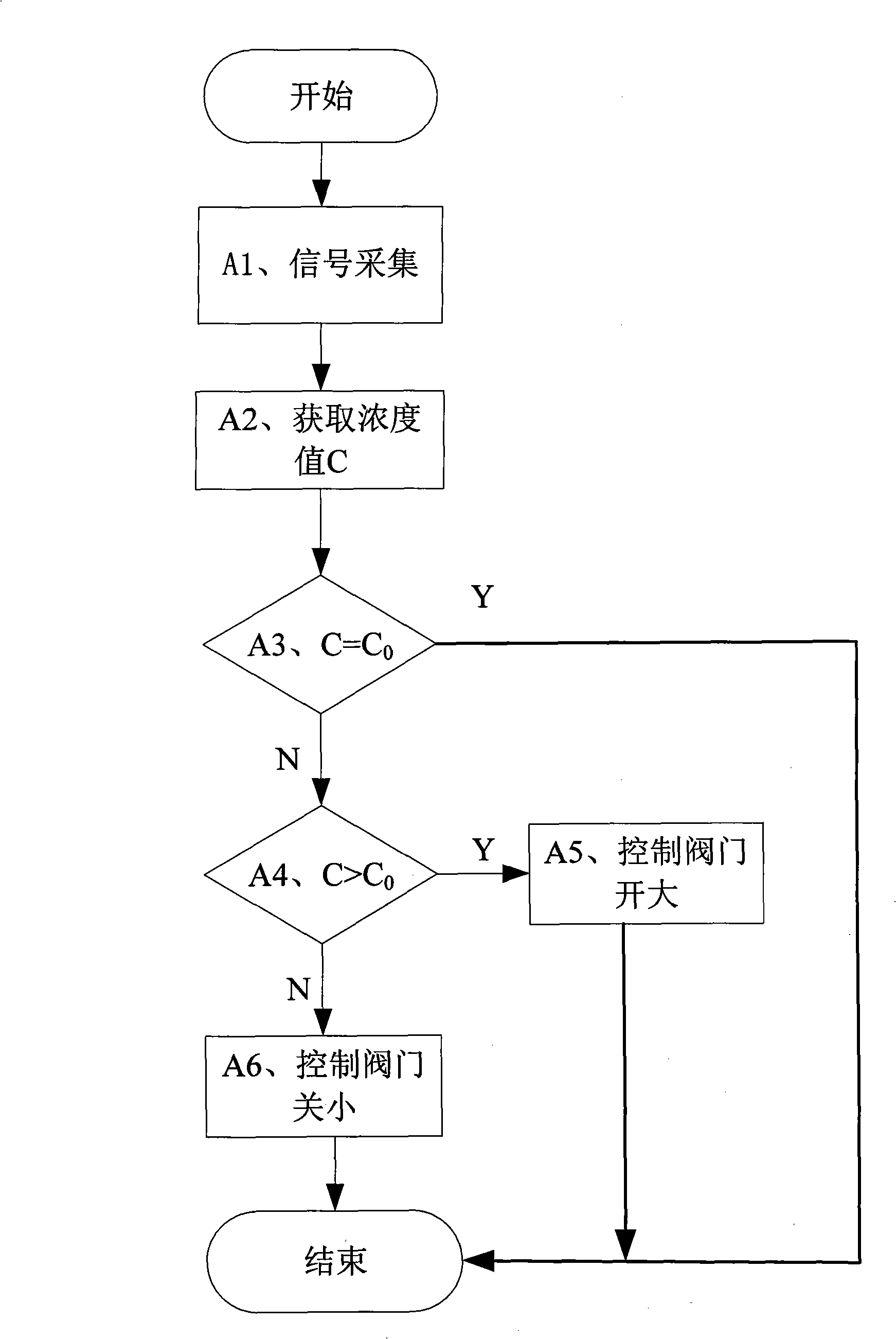

[0040] refer to Figure 5 , to further illustrate the mud discharge control proce...

Embodiment 3

[0048] Referring to Fig. 6, it is a structural schematic diagram of another central drive single-pipe dredger of the present invention, and its structural difference from Embodiment 1 is that: the sludge interface instrument 14 is used to collect the sludge state signal of the sedimentation tank, and set In the sedimentation tank 13, the sludge layer height H at the bottom of the sedimentation tank 13 is collected in real time, and the sludge layer height H signal is transmitted to the controller 9, and the controller 9 judges the sludge state at this time according to the sludge layer height H signal , control the electric actuator 10 to adjust the opening of the sludge valve 11 and the sludge layer height H signal is proportional to the relationship. Due to the large surface area of the sedimentation tank and the disturbance of the bottom water flow, it may be difficult for the height of the sludge layer at a certain point or in a small area to represent the status of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com