Strong-shear mixing machine

A mixer and mixing drum technology, applied in mixers, mixers with rotary mixing devices, and dissolving directions, can solve the problems of affecting mixing uniformity, mixing inefficiency, and reducing mixer efficiency, and increase the shear probability. , good mixing effect, improved shearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

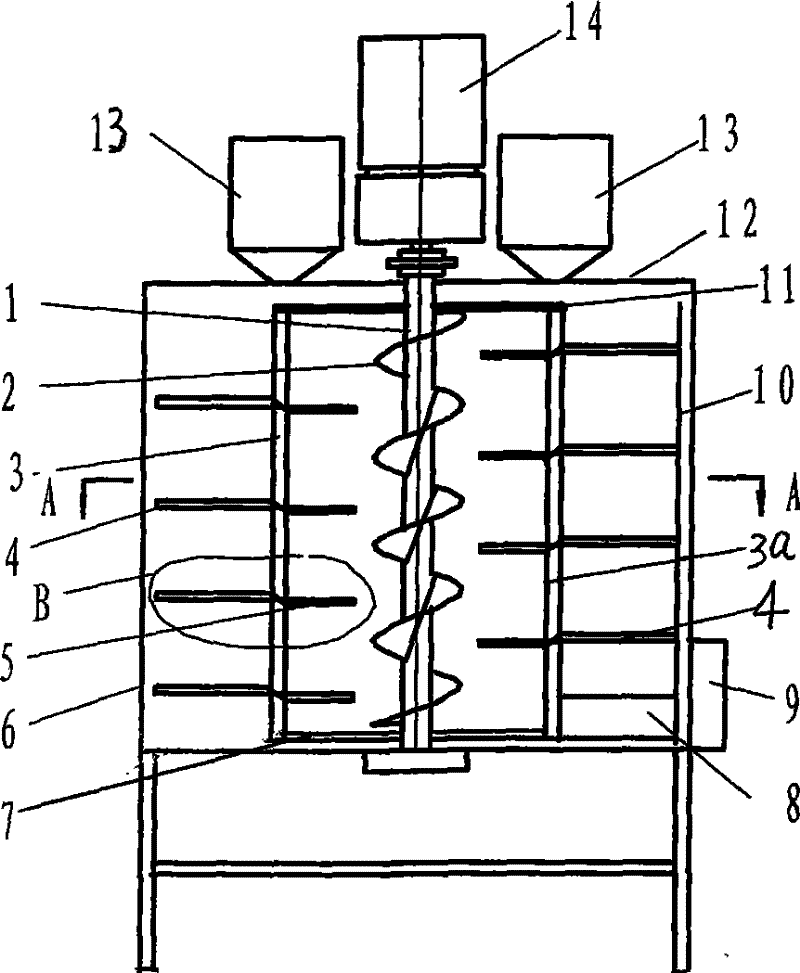

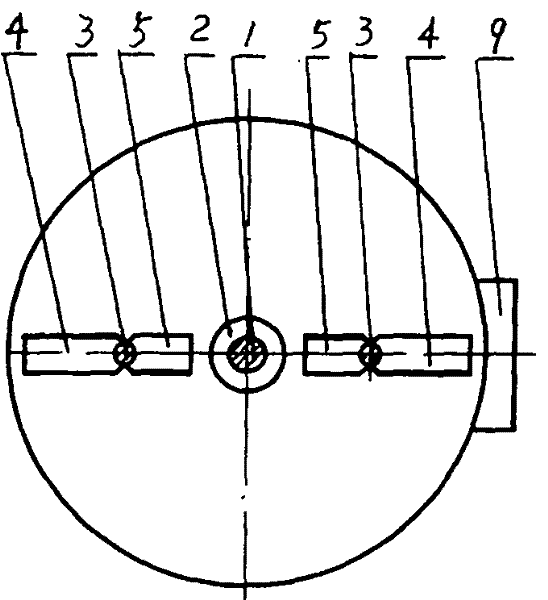

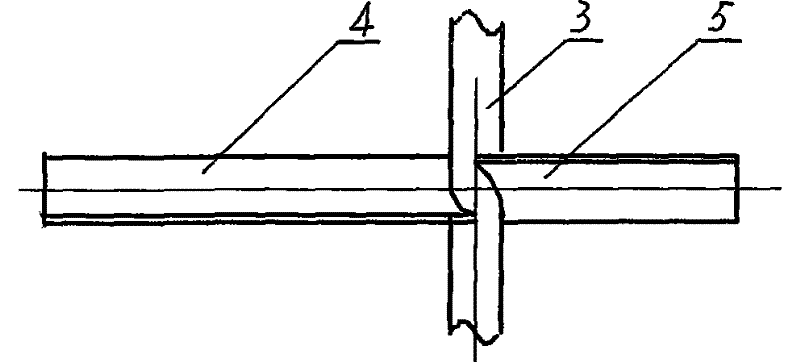

[0014] This strong shear mixer comprises a mixing drum 6, which has a feed inlet 12 on the mixing drum 6 and a discharge port 9 on its lower part, and a power unit 14 is installed on the upper top surface of the mixing drum 6, and the top surface also has The additive cylinder 13 communicated with the inner cavity of the mixing drum; the rotor located in the mixing drum is driven by the power device 14; the rotor is composed of a rotating shaft 1, a helical blade 2 mounted on the rotating shaft 1 and a stirring device located on both sides of the rotating shaft; The stirring device includes a paddle bar, an outer paddle blade 4 and an inner paddle blade 5 mounted on the paddle bar. Both the outer paddle blade and the inner paddle blade have an inclination angle α with the horizontal direction, and the inclination angle α is 15°, and the outer paddle blade and the inner paddle blade are 15°. The projections of the inner paddle blades at the center of the paddle shaft intersect. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com