High effective concentration magnetic separator for concentrating strongly magnetic mineral

A strong magnetic and magnetic separator technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increasing the difficulty of concentration and filtration operations, difficulty in solid-liquid separation of final products, poor concentration effect, etc., to achieve dehydration The effect is remarkable, the tumbling intensity is intense, and the effect is flexible to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

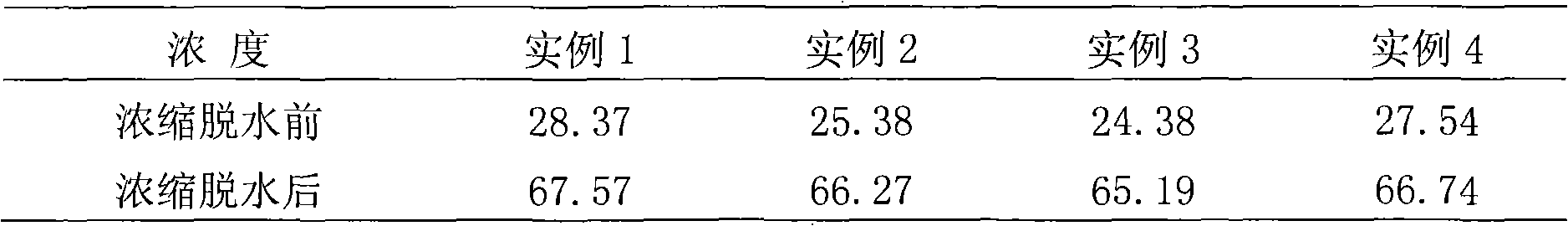

Examples

Embodiment Construction

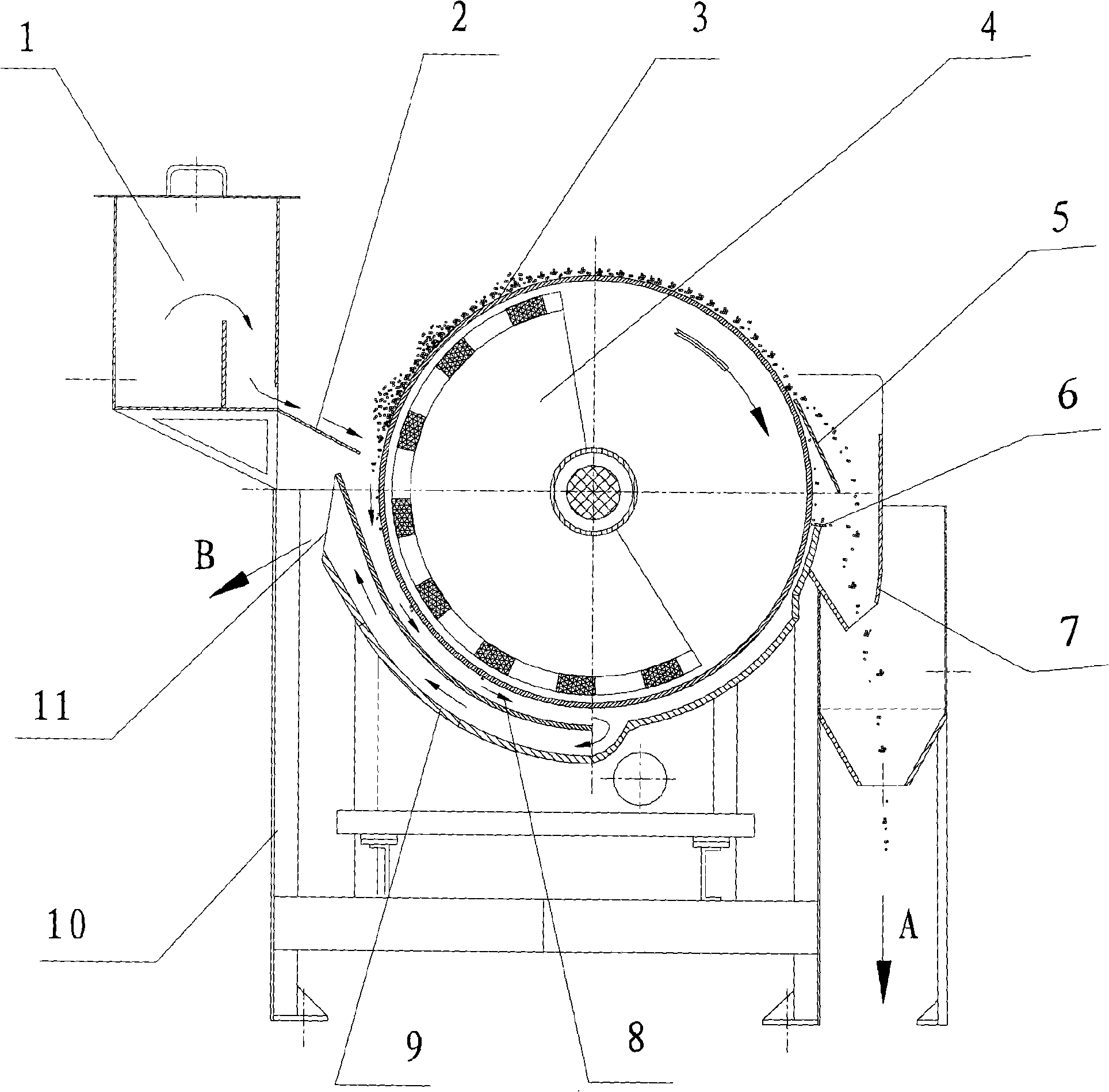

[0018] Such as figure 1 As shown, the high-efficiency concentration magnetic separator for the concentration of strong magnetic minerals includes a feeding box 1, a deflector 2, a cylinder 3, a permanent magnet 4, an unloading plate 5, a damping plate 6, and a collecting bucket 7. Sorting plate, bottom box 9, frame 10; Cylinder 3 is a cavity, and permanent magnet 4 is arranged in the cavity of cylinder 3, and permanent magnet 4 is fixedly connected with cylinder 3, and the shaft on cylinder 3 The two ends are respectively connected by bearings with the frame 10 (that is, the cylinder can rotate under the action of the transmission mechanism), and the shaft on the cylinder 3 is connected with the transmission mechanism; The upper end surface is an arc-shaped surface, and the bottom box 9 is fixedly connected with the frame 10 (such as welding or bolting); a sorting plate is arranged between the cylinder 3 and the bottom box 9, and the sorting plate is located at the left part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com