High-cleanliness cleaning and treating system for PET recovered bottle pieces

A treatment system and cleanliness technology, which is applied in the field of recycling PET bottle flake cleaning system, can solve the problems of increasing environmental pollution of wastewater and hindering the expansion and application of recycled PET bottle flakes, so as to achieve the improvement of waste water reuse rate, environmental protection optimization, The effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

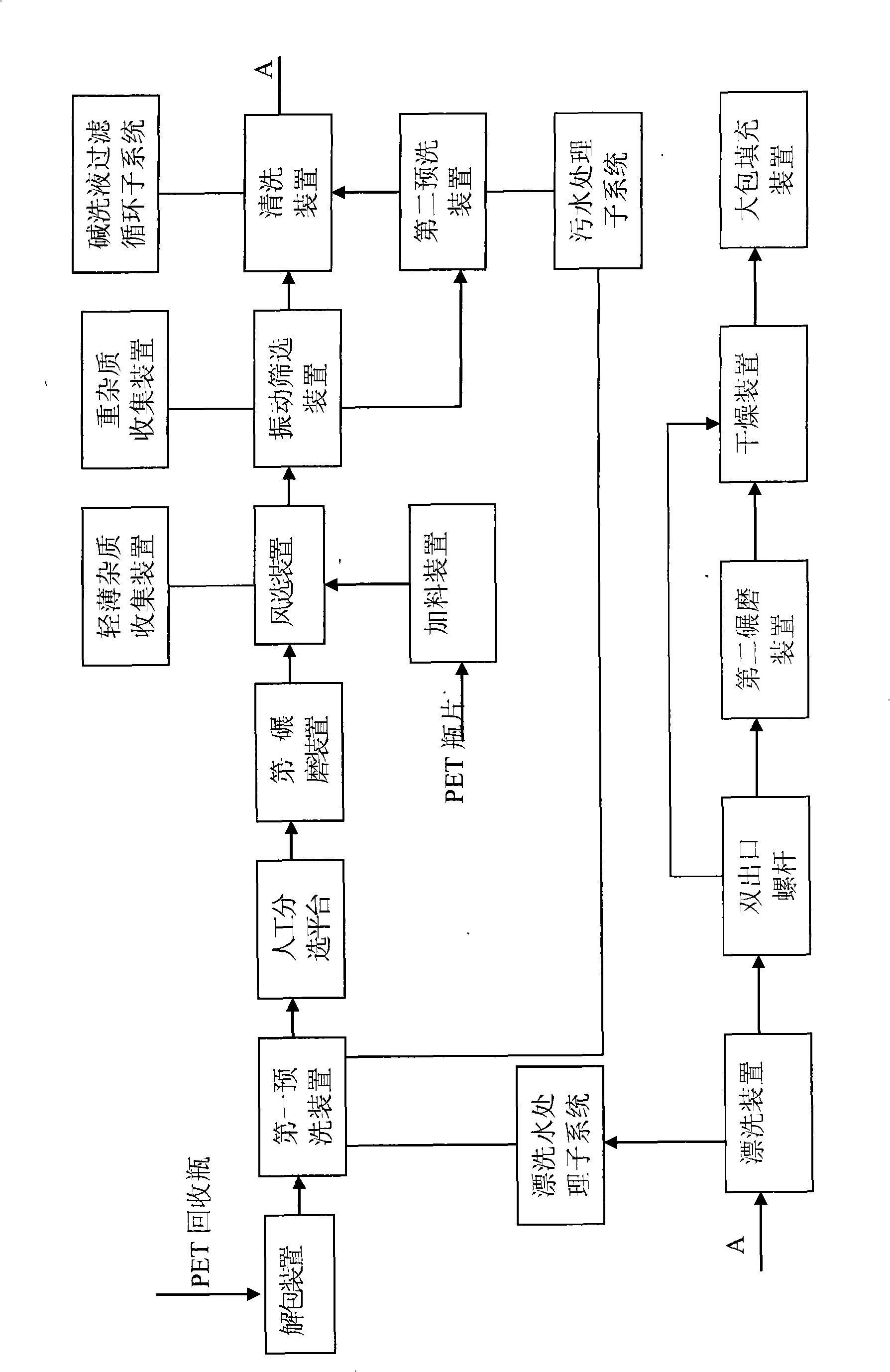

[0014] in such as figure 1 In the system shown, the cleaning device and the vibrating screening device are modified accordingly for the purpose of the present invention. One is the cleaning reactor in the cleaning device, and enough raised parts are evenly installed on the inner wall of the reactor to increase the friction between the bottle flakes in the reactor; the other is the vibration screening device, and the vibration panel is covered with small holes It is distributed in the shape of a plum blossom, and the diameter of each hole is 3mm. When the bottle flakes pass by, dust and other small impurities fall into the collection box through the small holes; a certain number of V-shaped metal strips are evenly arranged on the vibrating panel, and the thickness is 1mm. Vertically welded with the panel, the metal strips The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com