Steam chamber cloth feeding port dripping-proof heater plate

A technology of anti-drip and cloth inlet, which is applied in textile processing machine accessories, textile material processing, textiles and papermaking, etc., can solve problems such as the impact of process implementation, and achieve the effect of changing varieties and process convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

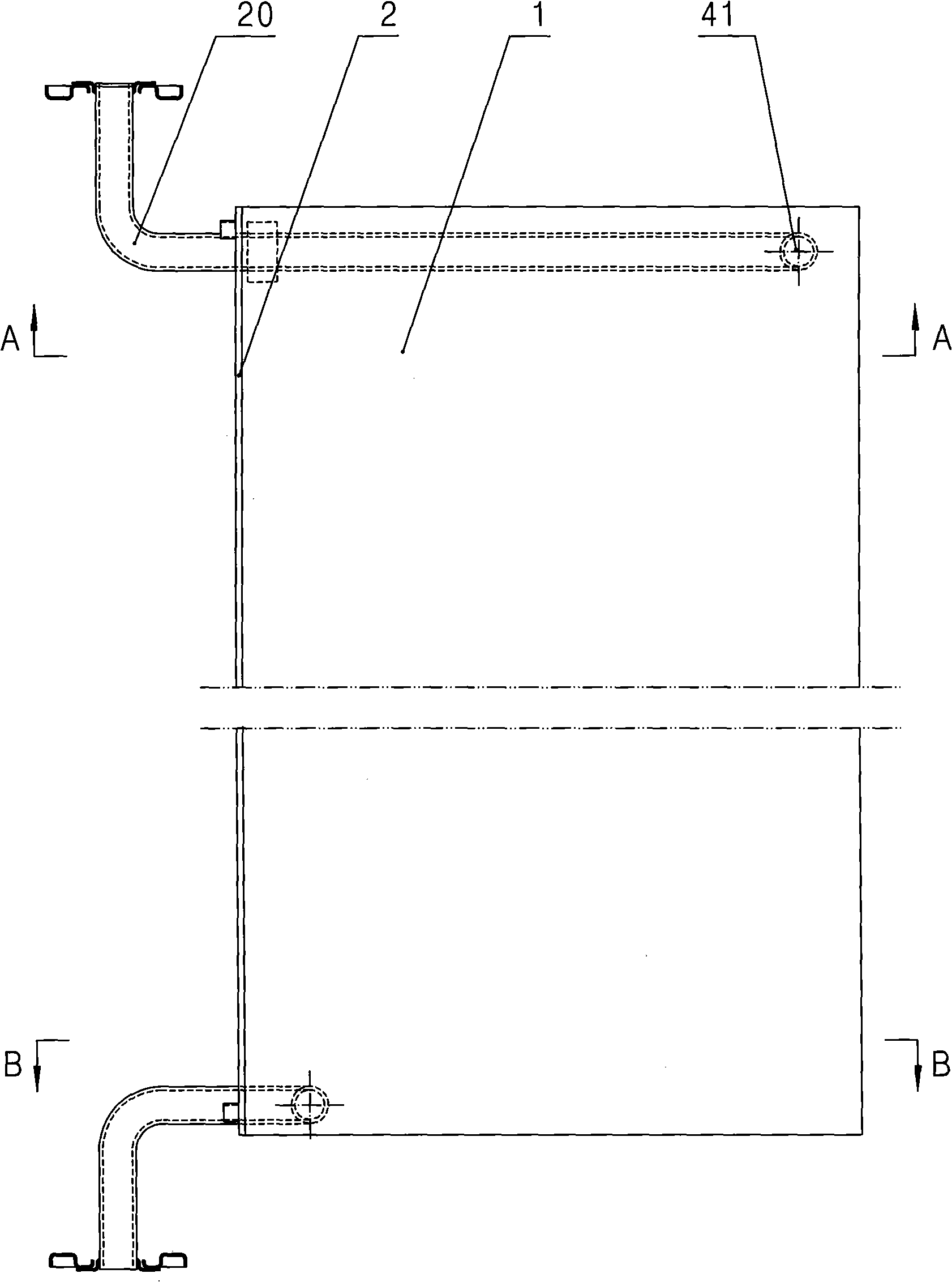

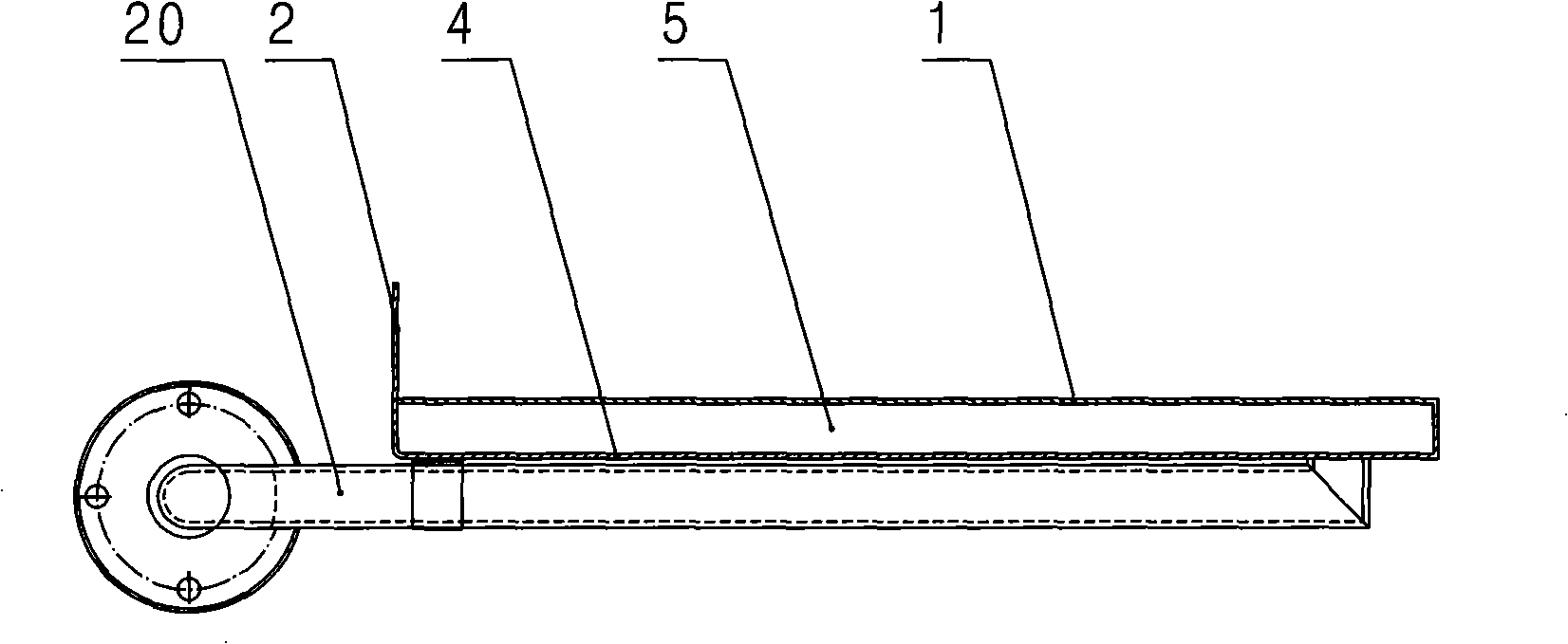

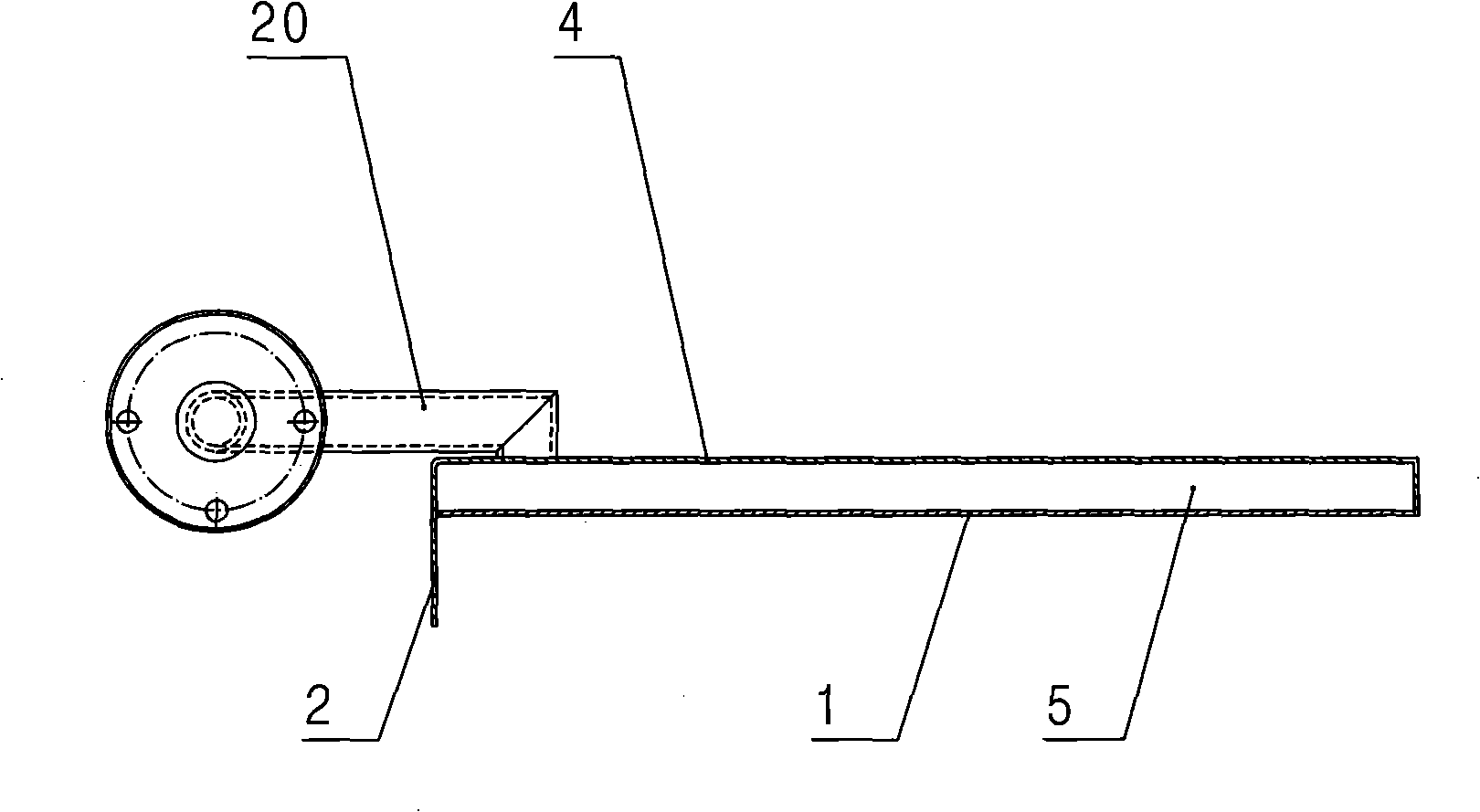

[0029] Such as Figure 4 , Figure 5 As shown, the anti-drip heating plate of the cloth inlet of the steam box described in this embodiment includes: a hollow plate 1, and a pair of heating chambers 5 communicating with the heating chamber 5 in the hollow plate 1 are provided on the bottom surface 4 of the hollow plate 1. Vent holes 41, the pair of vent holes 41 are diagonally arranged, of course, the pair of vent holes 41 can also be arranged relative to the left and right, and the inner and outer sides of the hollow plate 1 are respectively provided with baffles higher than the upper plane. Liquid chimes 3 and 2. In addition, the upper side of the hollow plate 1 is also passed through four such as Image 6 The shown support block 9 is provided with a detachable liquid baffle 8 - the liquid baffle 8 can be placed directly on the support block 9, or a buckle mechanism can be added, this structure can facilitate the removal of the liquid baffle 8 Cleaning; a heat insulation ...

Embodiment 2

[0031] Such as Figure 7 , Figure 8 with Figure 9 As shown, the anti-drip heating plate of the cloth inlet of the steam box described in the present embodiment includes: a hollow plate 1, and a pair of through holes communicating with the cavity in the hollow plate 1 are arranged on the bottom surface 4 of the hollow plate 1. The steam holes 41, the pair of steam holes 41 are diagonally arranged, of course, the pair of steam holes 41 can also be arranged opposite to the left and right, and the inner and outer sides of the hollow plate 1 are respectively provided with liquid barriers higher than the upper plane. Knurling 3 and 2. In addition, the hollow plate 1 is also provided with a transverse partition 6, which divides the cavity in the hollow plate 1 into a heating cavity 5 and a heat insulating cavity 7, and the heat insulating cavity 7 is a natural cavity. The vent hole 41 communicates with the heating chamber 5. In order to increase the heat insulation effect of th...

Embodiment 3

[0033] Such as Figure 10 , Figure 11 As shown, the anti-drip heating plate of the cloth inlet of the steam box described in the present embodiment includes: a hollow plate 1, and a pair of through holes communicating with the cavity in the hollow plate 1 are arranged on the bottom surface 4 of the hollow plate 1. The steam holes 41, the pair of steam holes 41 are diagonally arranged, of course, the pair of steam holes 41 can also be arranged opposite to the left and right, and the inner and outer sides of the hollow plate 1 are respectively provided with liquid barriers higher than the upper plane. Knurling 3 and 2. In addition, described hollow plate 1 is also provided with such as Figure 11 , Figure 12 The horizontal partition 6 of the concave-convex structure shown divides the cavity in the hollow plate 1 into a heating cavity 5 and a heat-insulating cavity 7. The heat-insulating cavity 7 is a natural cavity. The steam vent 41 and the heating cavity 5 connected. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com