Thermoelectric generating set auxiliary machinery fault fast-reducing load feed water pump trip behavior feasibility determination method

A technology for the failure of thermal power generating units and auxiliary units. It is applied in pump testing, water supply control, machine/engine and other directions. It can solve problems such as unit tripping, low drum water level, and water supply, so as to improve the level of safe operation and improve the success rate. , increase the effect of targeting and effectiveness

Active Publication Date: 2008-11-19

STATE GRID HEBEI ELECTRIC POWER RES INST +2

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although domestic and foreign experiments and analyzes have been carried out on the RUNBACK working condition of the feed water pump of many units, the water level of the steam drum is often too low when the feed water pump is in the RUNBACK working condition of the large-scale unit, causing the unit to trip.

For a large 600MW unit, when a group of water pumps trips, it is difficult to adjust the load distribution of steam pumps and electric charges in a timely manner even if the backup pumps are started together, resulting in a serious shortage of water supply in a short period of time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

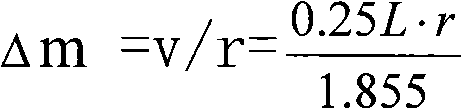

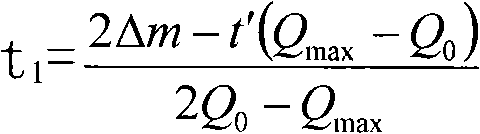

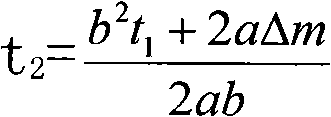

The invention relates to a method for determining feasibility of the working condition of water feed pump tripping operation by runback of auxiliary failure of a thermal generator set. The method comprises the following steps that: (1) the water deficit amount allowed by a boiler steam header is determined when the water feed pump tripping operation runs back; (2) the smallest beginning time of the runback t1 is determined; (3) the smallest continuous time of the runback t2 is determined. The method has the advantages that: the method can carry out determination and evaluation to the feasibility of water feed pump runback and improve the success rate of the water feed pump runback and the safe operation level of the generator set.

Description

Feasibility determination method for rapid load reduction feedwater pump tripping condition of thermal power generation unit auxiliary equipment failure technical field The patent of the present invention relates to a method for determining whether the unit can operate safely when the auxiliary machine of the thermal power generation unit fails (trips) and the unit quickly reduces load (hereinafter referred to as RUNBACK) (feed water pump tripping condition). Automatic control and protection system for large generator sets. technical background In the actual operation of the steam drum boiler of a large-scale unit, the water level is too high or too low will lead to serious accidents. In order to ensure the safe operation of the unit, there are strict requirements on the boiler drum water level control. Although domestic and foreign experiments and analyzes have been carried out on the RUNBACK working condition of the feed water pump of many units, the water level of the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04B51/00F22D5/00

Inventor 彭钢高志存徐新航刘永红张洪涛

Owner STATE GRID HEBEI ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com