Process and apparatus for producing yarn and gland packing

A technology of a manufacturing device and a manufacturing method, which is applied to the field of yarn gland packing, can solve problems such as no production involved, and achieve the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

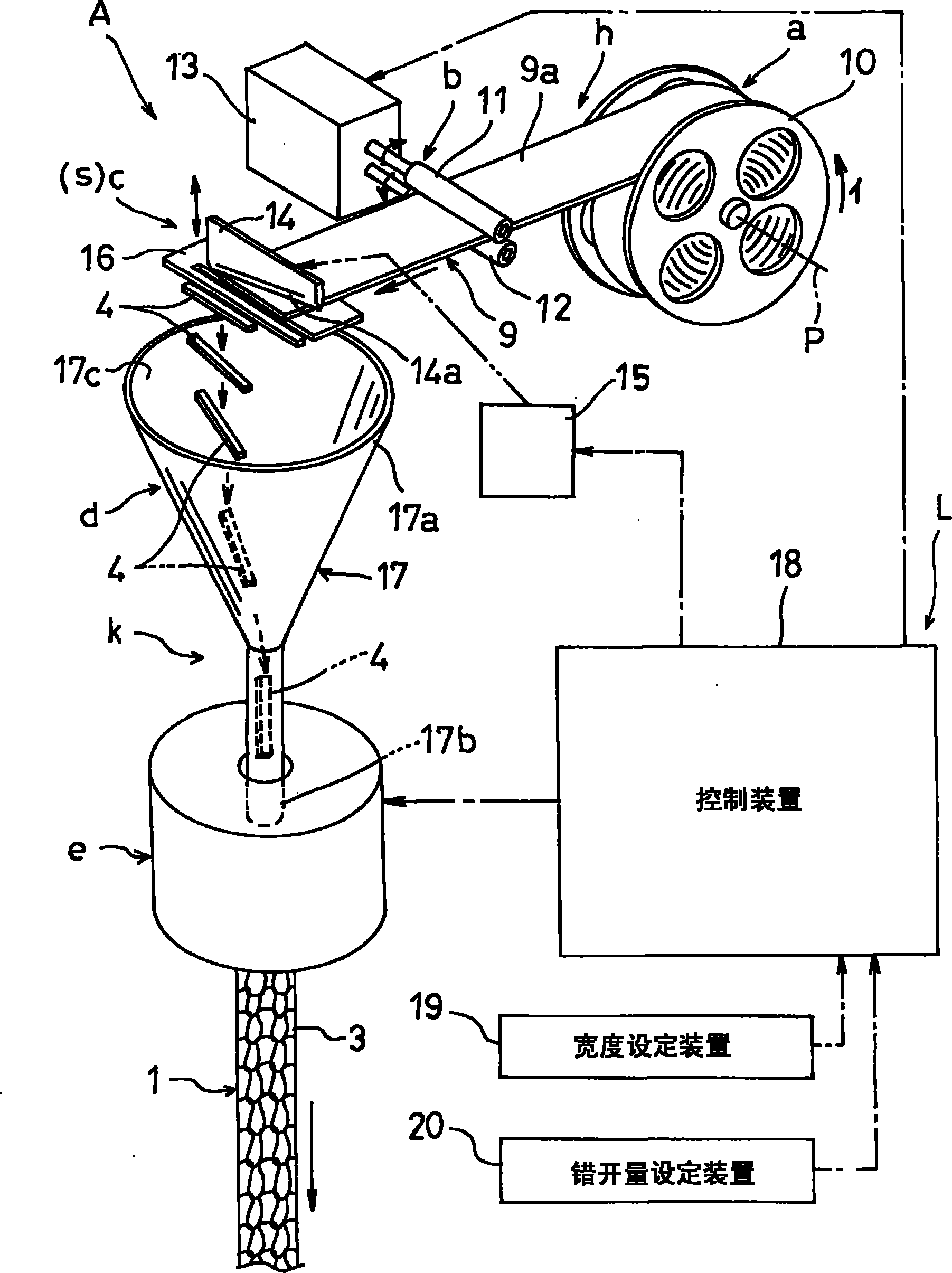

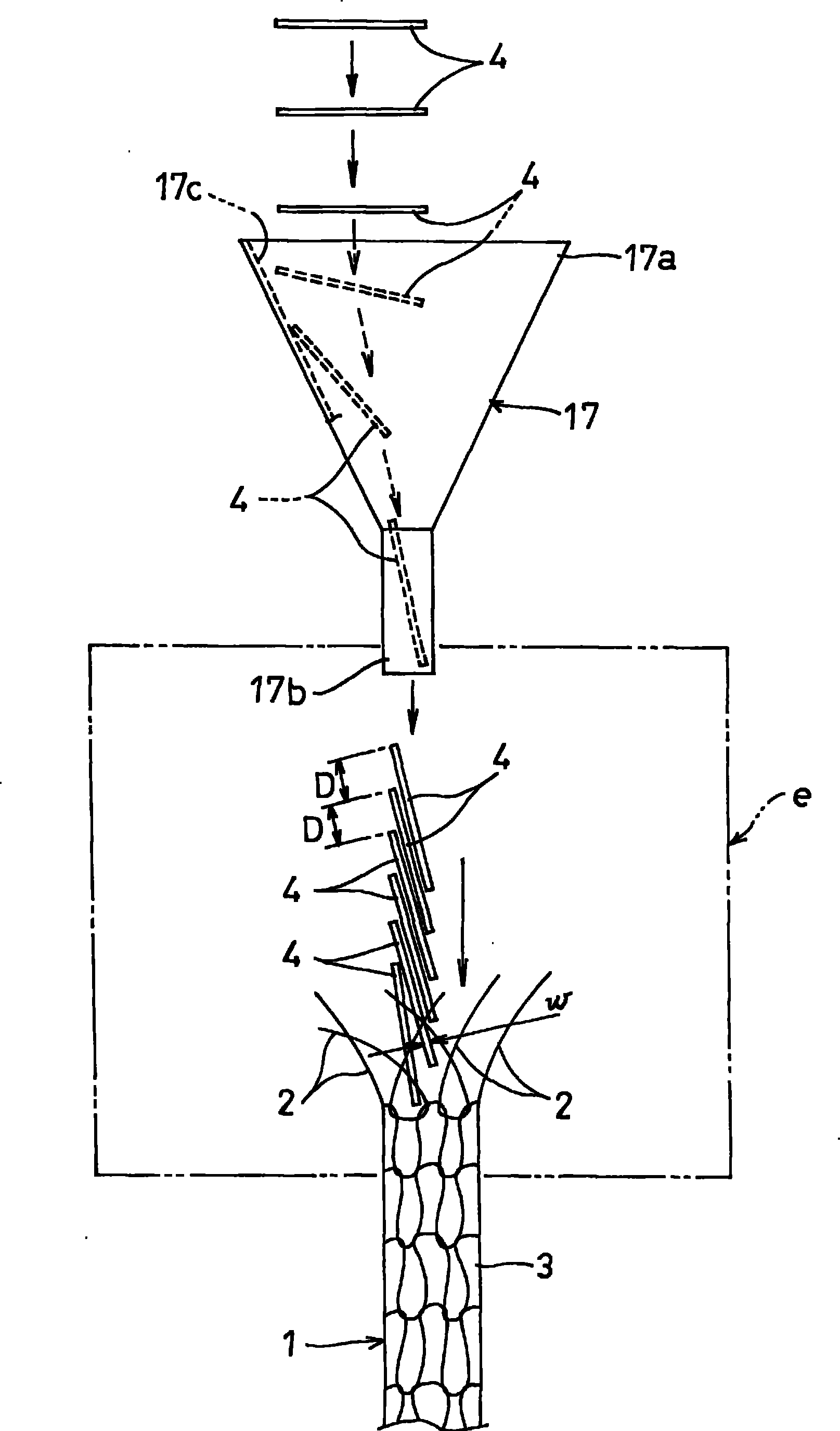

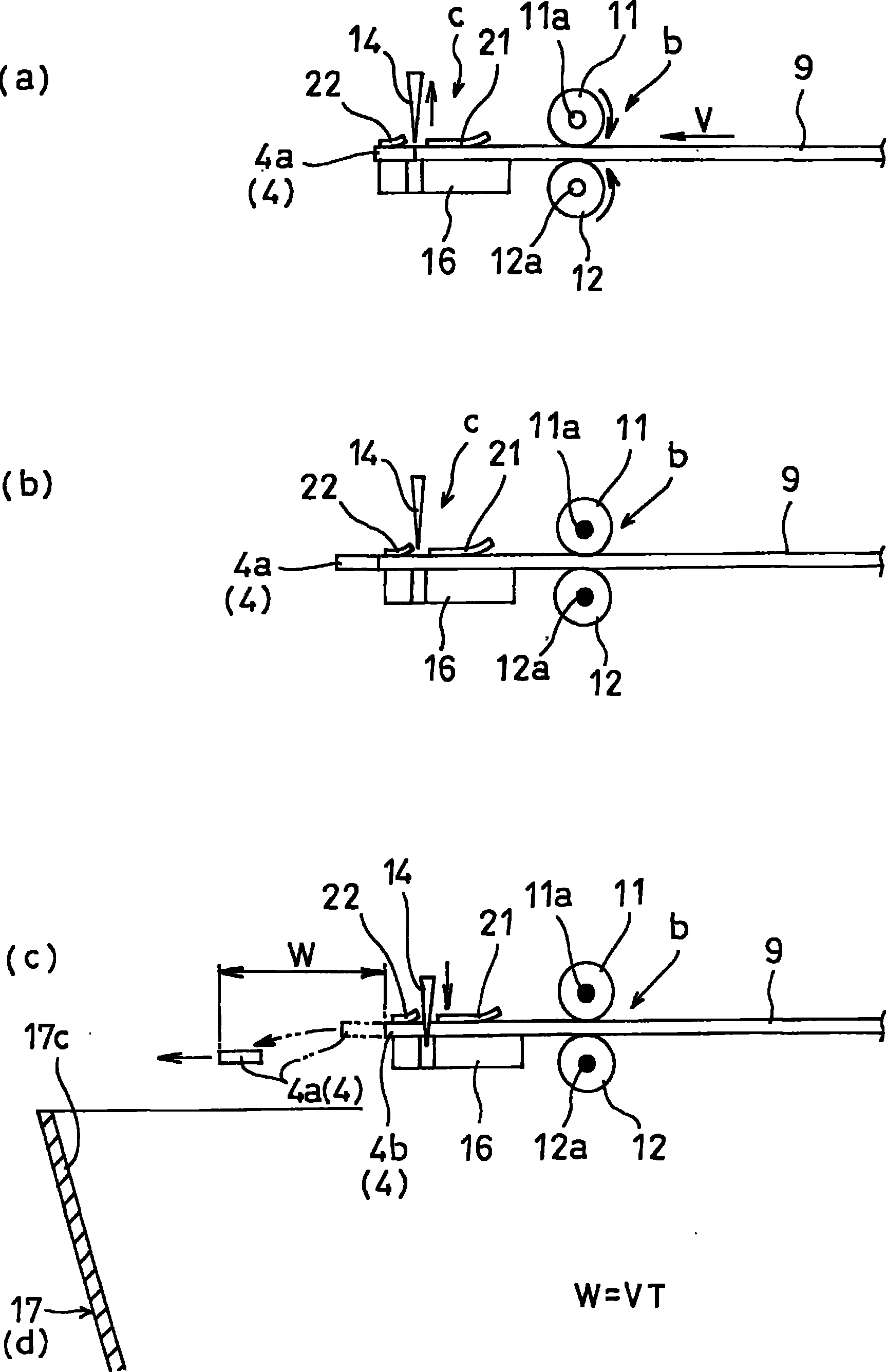

[0099] The yarn of the first embodiment was produced in the following manner using the above-mentioned production method. A plurality of expanded graphite materials 4 having a rectangular cross-sectional shape of thickness t 0.38 mm×width w 1.0 mm and a length of about 200 mm are filled into the cylindrical member 3 while shifting the positions of these ends by 20 mm to produce a cross-sectional shape The cylindrical member 3 is braided (knitted) using a nichrome wire (or stainless steel wire, etc.) with a diameter of about 0.1 mm as the fiber material 2 as a circular (circular) yarn 1 . That is, it is an example of setting the shift amount D=20 mm of the ends of the expanded graphite material 4 4 . The aspect ratio h of the expanded graphite material 4 in the first yarn 1 of the first embodiment is h=1.0 / 0.38≈2.63, and the weight is 5 g / m.

[0100] image 3 , represents the gland packing 5 made with the yarn 1 of the first embodiment. This gland packing 5, after being wove...

no. 2 example

[0102] The yarn of the second embodiment was produced in the following manner using the above-described production method. While the ends of the expanded graphite material 4 with a cross-sectional size of 0.38 mm in thickness, 1.0 mm in width, and 200 mm in length are respectively staggered by 30 mm, they are collected into bundles of elongated parts, and their outer circumference is covered with a cylindrical part 3, thereby making a cross-sectional shape of The circular yarn 1 and the above-mentioned tubular member 3 are woven by a knitting method using a fiber material 2 made of a nichrome wire having a wire diameter of 0.1 mm. That is, it is an example in which the amount of deviation D of the ends of the expanded graphite material 4 is set to 30 mm. The aspect ratio h of the expanded graphite material 4 in the second yarn 1 of the second embodiment is h=1.0 / 0.38≈2.63, and the weight is 4 g / m.

[0103] After weaving with 8 yarns 1 of the second embodiment, the surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com