Homogenization treatment process for high-temperature alloyed steel ingot

A homogenization treatment, high-temperature alloy steel technology, applied in the direction of heat treatment equipment, heat treatment process control, manufacturing tools, etc., to achieve the effect of improving the degree of segregation

Inactive Publication Date: 2008-11-26

JIANGSU TOLAND ALLOY

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the Laves phase is eliminated, there are quite serious grain bands between coarse and fine grains, and the δ phase is densely distributed in the fine grain bands

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

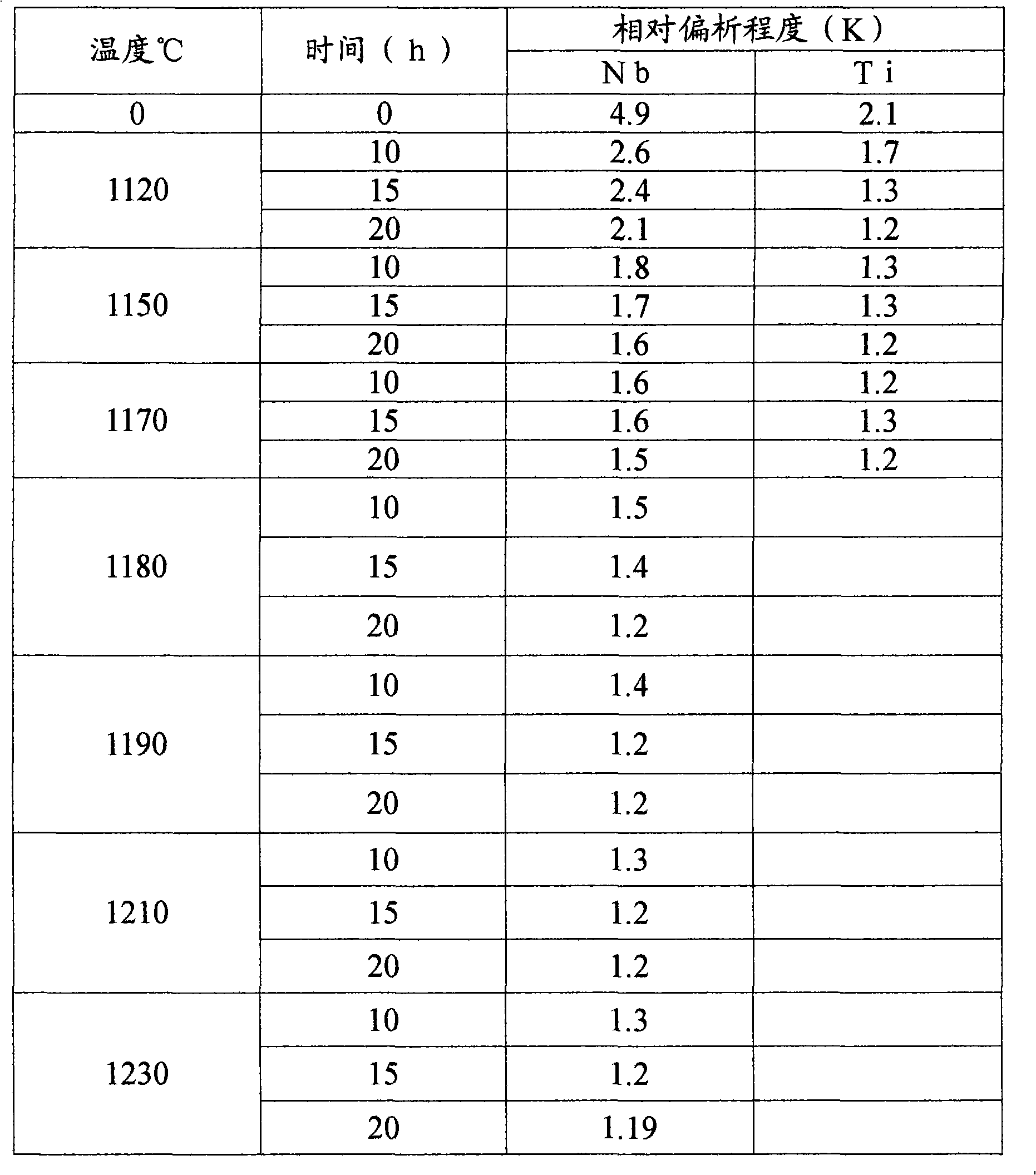

A homogenizing treatment method for high-temperature alloy ingots is annealing treatment in an annealing furnace. The method is characterized in that the temperature of the annealing treatment is between the temperature of 1180 to 1230 DEG C and the annealing lasts for twenty hours. The method of the invention adopts the technical proposal, so the method can effectively solve the problem of segregation between the phase Laves and the phase delta and improves the alloy segregation degree to the utmost extent.

Description

technical field The invention relates to a high-temperature alloy processing technology, in particular to a method for homogenizing high-temperature alloy steel ingots. Background technique GH169 superalloy is an iron-nickel-based alloy containing up to 5% niobium. Due to its composition characteristics, it determines the serious segregation of the alloy elements, especially the segregation of Nb, and the limitation of cooling speed, resulting in the ingot after cooling. Laves phase and δ phase must be formed in the as-cast structure, and the existence of Laves phase in the alloy leads to the low plasticity of the ingot. Domestic research on this has achieved certain results. For example, for the Φ360 ingot type, the Laves phase can be basically eliminated by uniform treatment at 1120°C for 24 hours or 1150°C for 15 hours. Although the Laves phase is eliminated, there are quite serious grain bands between coarse and fine grains, and the δ phase is densely distributed in the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D1/26C21D11/00

Inventor 万金宜张建国万中度

Owner JIANGSU TOLAND ALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com