Processing technology for divisionally plating and coating hub and special protective clothing

A technology of partitioned electroplating and processing technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems that have not been widely used, the quality of electroplating is difficult to guarantee, the coating is bruised, scratched, etc., and it is convenient Promote the use, low cost of production and use, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

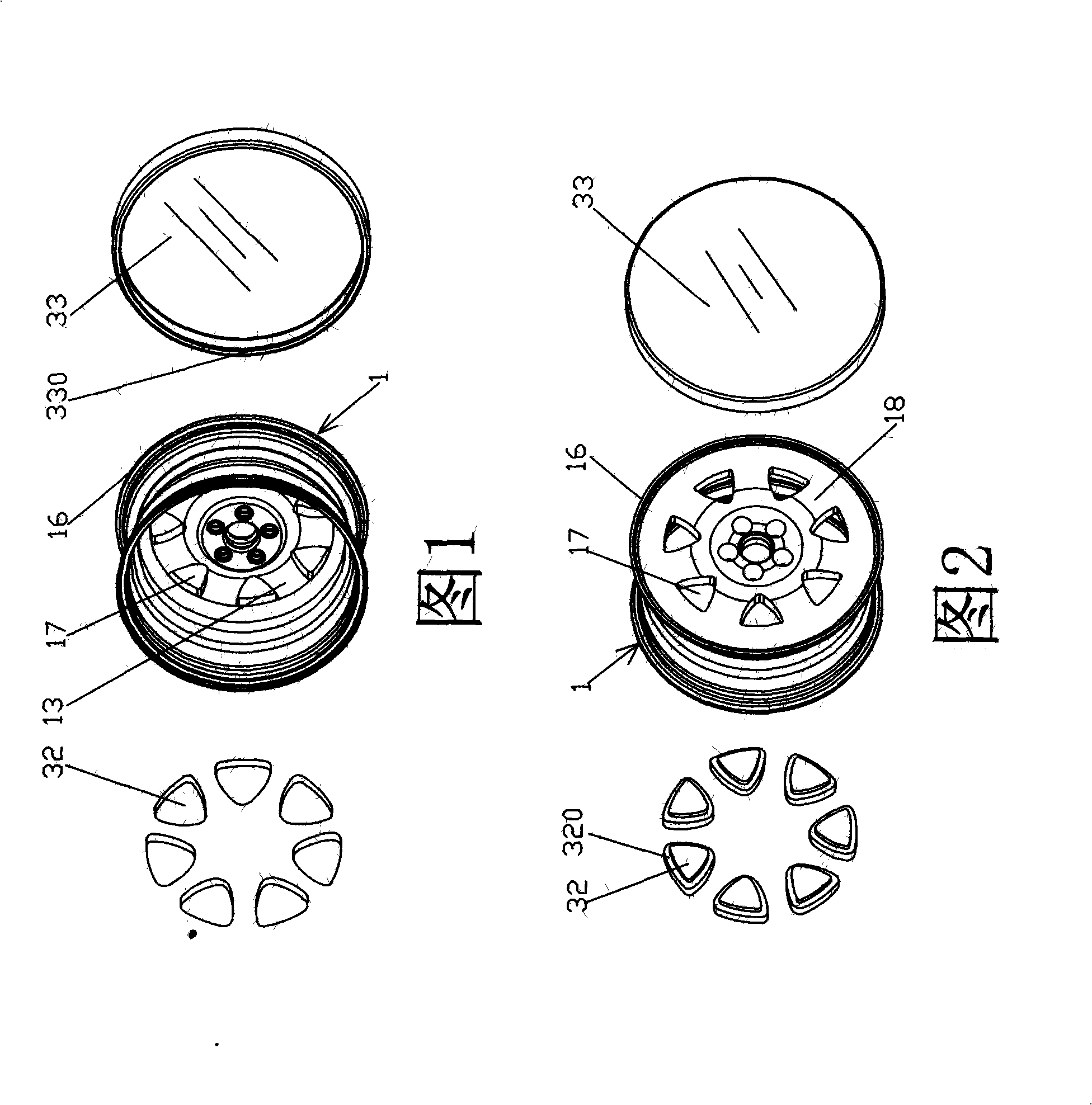

[0038] A processing technology for partitioned electroplating and coating wheel hubs, which includes the following steps:

[0039] a: Manufacture a wheel hub 1 blank with a predetermined shape. The spoke profile on the wheel hub 1 blank can be a combination of various irregular geometric shapes, or it can be a regular geometric shape. The processing technology of the present invention is not affected by the wheel hub 1 blank. shape constraints;

[0040] b: Polish the surface of the wheel hub 1 blank, so that the polished hub 1 meets the electroplating requirements;

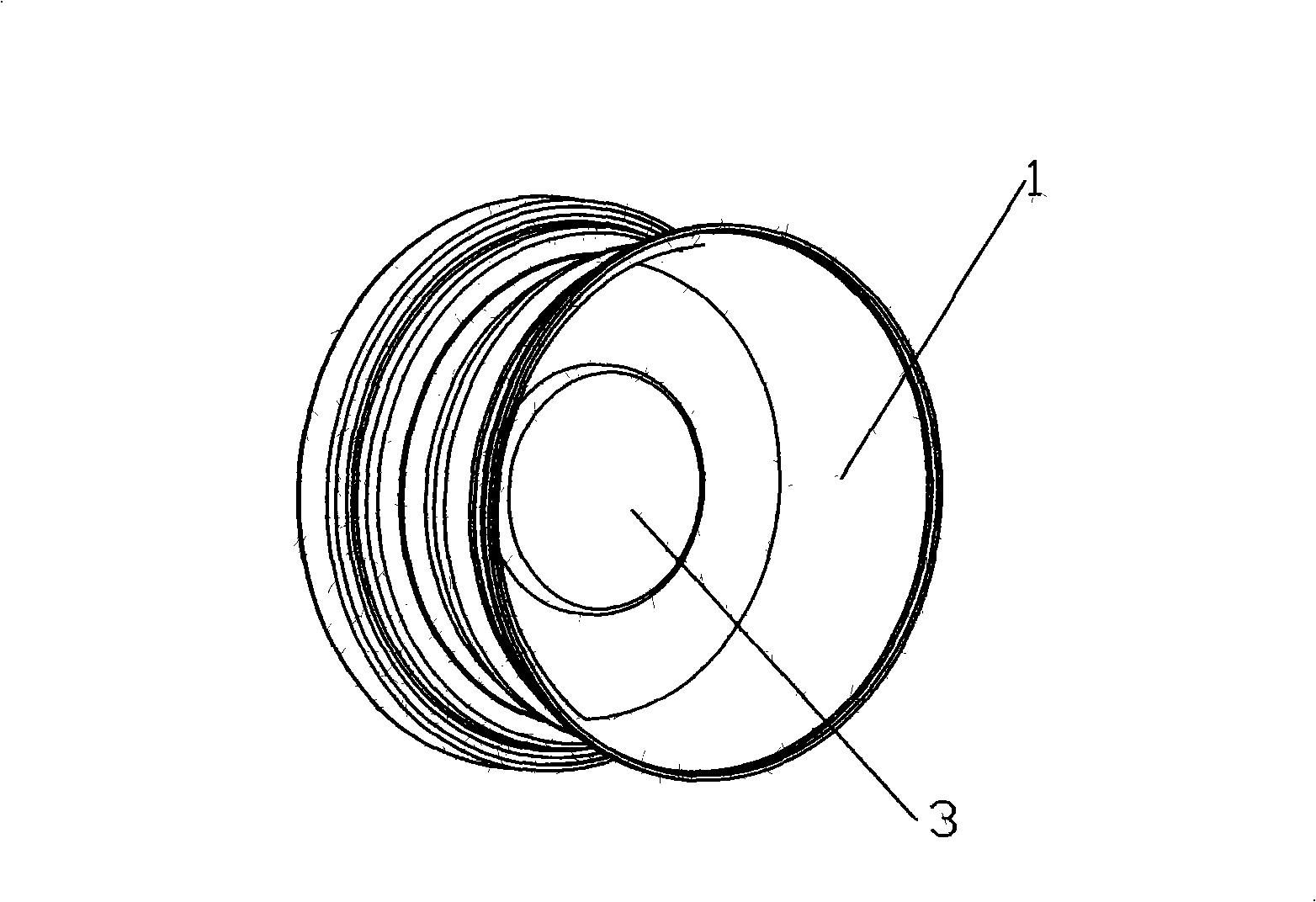

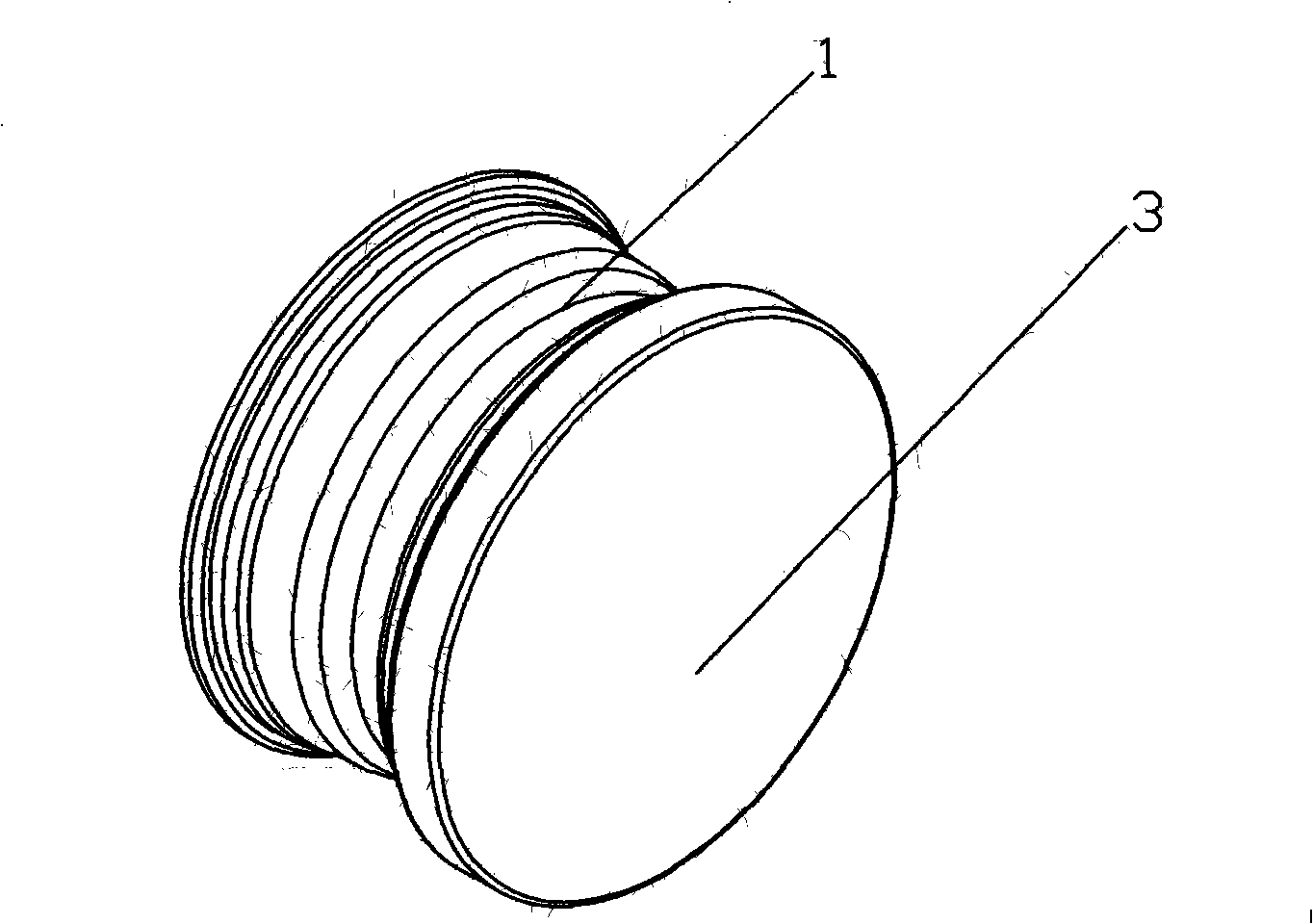

[0041] c: Manufacture a protective device 3 that can cover the surface to be electroplated on the wheel hub 1 according to the shape of the wheel hub 1, so that the surface to be electroplated on the wheel hub 1 is covered by the protective device 3;

[0042] d: Spray the coating resist material on the hub 1 with the protector 3, and then bake the sprayed resist material to make it solidify, so that a permanent p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com