Process for changing wet storage holders to be rubber diaphragm sealed waterless gas-holder

A technology of wet gas storage cabinet and rubber membrane, which is applied in the direction of adjustable capacity gas storage tank, gas/liquid distribution and storage, mechanical equipment, etc., which can solve the problems of large project investment and time-consuming, and save project investment and quality Reliable, structural strength and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

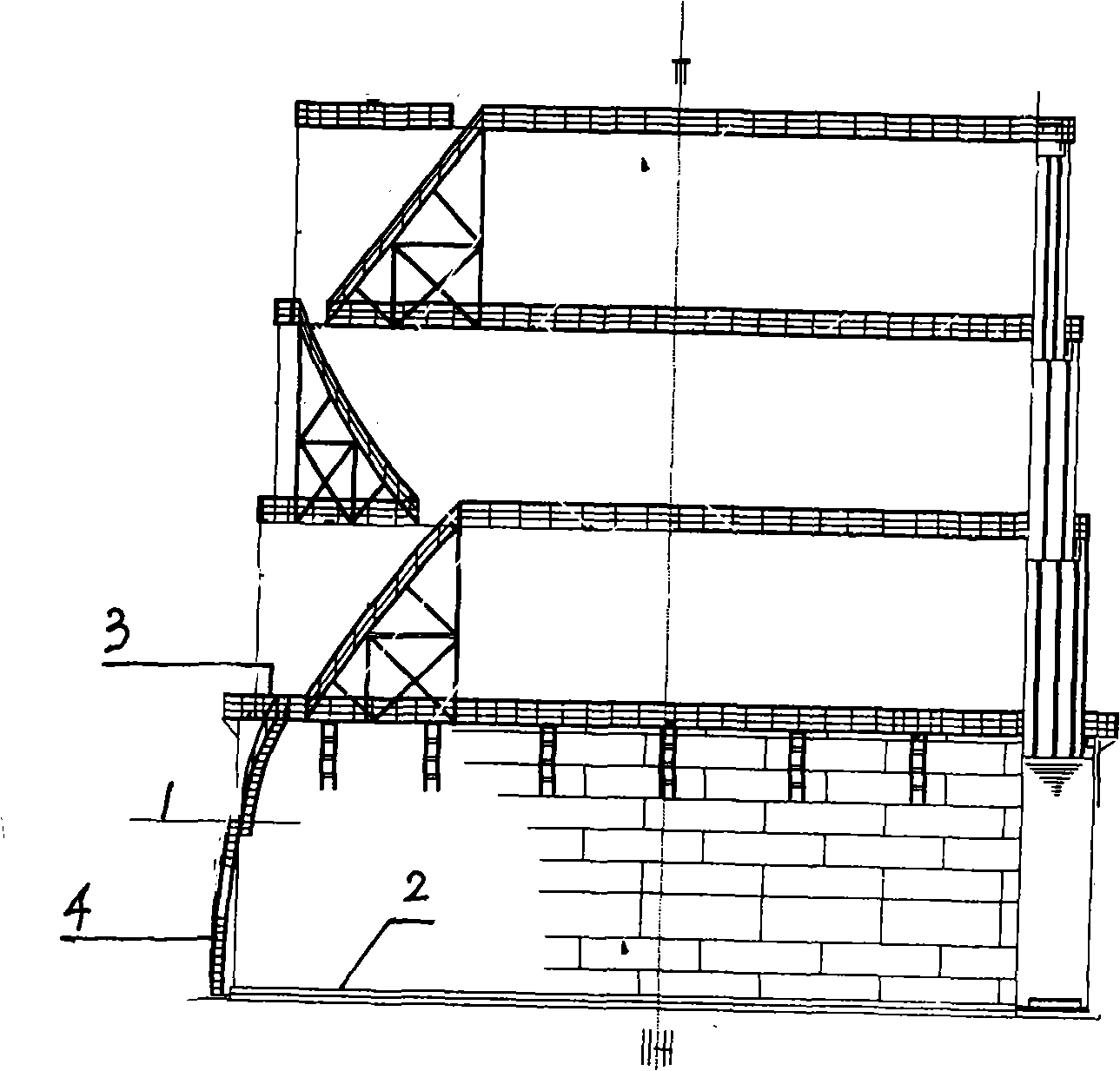

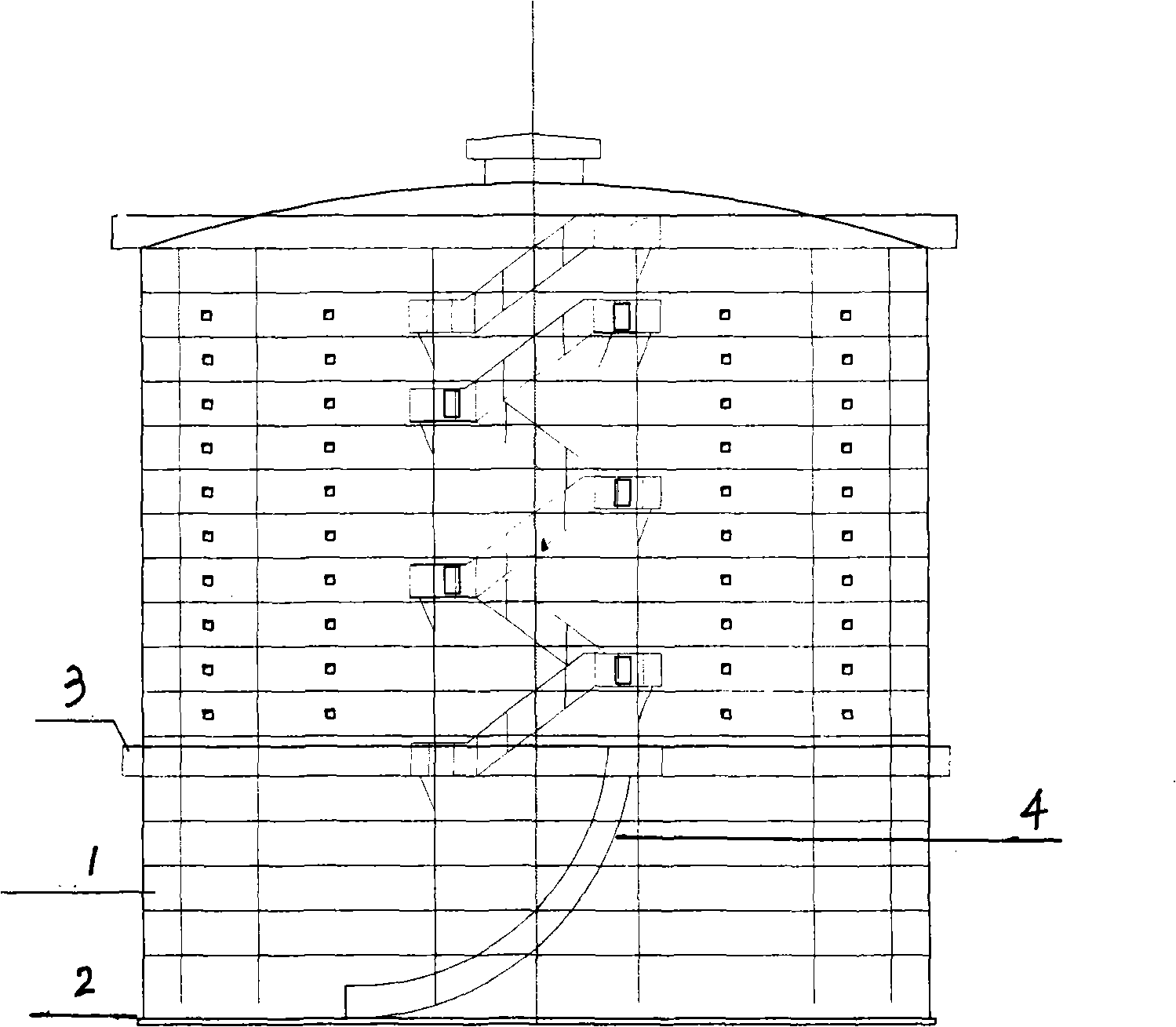

[0013] As shown in Figures 1 and 2: to rebuild the original wet-type spiral gas storage tank into a rubber-membrane sealed gas storage tank, first ① adjust the diameter of the rubber-membrane gas storage tank to make full use of the foundation of the original wet-type gas storage tank; ② The water tank wall plate 1 and the water tank bottom plate 2 of the original wet-type gas storage tank are respectively used as the lower end wall plate and bottom plate of the rubber membrane-sealed gas storage tank; ③ the water tank platform 3 of the original wet-type gas storage Wind ring beam; ④ Utilize the inclined ladder 4 of the original wet gas storage tank as the external inclined ladder of the rubber membrane sealed gas storage tank.

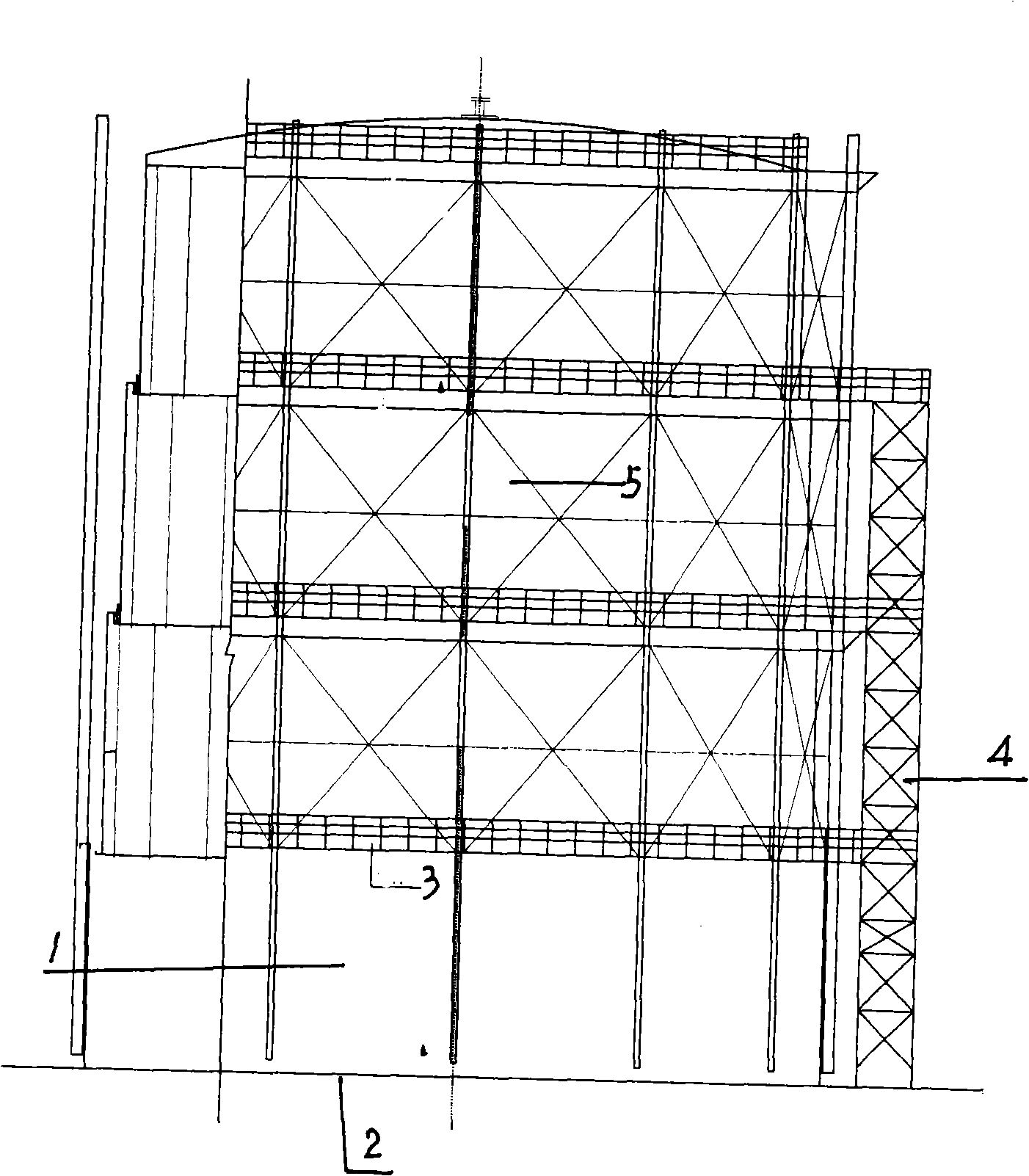

[0014] As shown in Figures 3 and 4: ① Adjust the diameter of the rubber membrane gas storage tank so that it can make full use of the foundation of the original wet gas storage tank; The lower wall and bottom plate of the rubber-membrane-sealed gashol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com