Evaporator of high-temperature high pressure natural circulation dry quenching coke waste heat boiler

A natural circulation and waste heat boiler technology, applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve the problems of large occupied space, difficult sealing of elliptical through holes, complex flue layout of shafts, etc. Convenience, beneficial to sealing treatment, and the effect of reducing the workload of manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the drawings and specific embodiments.

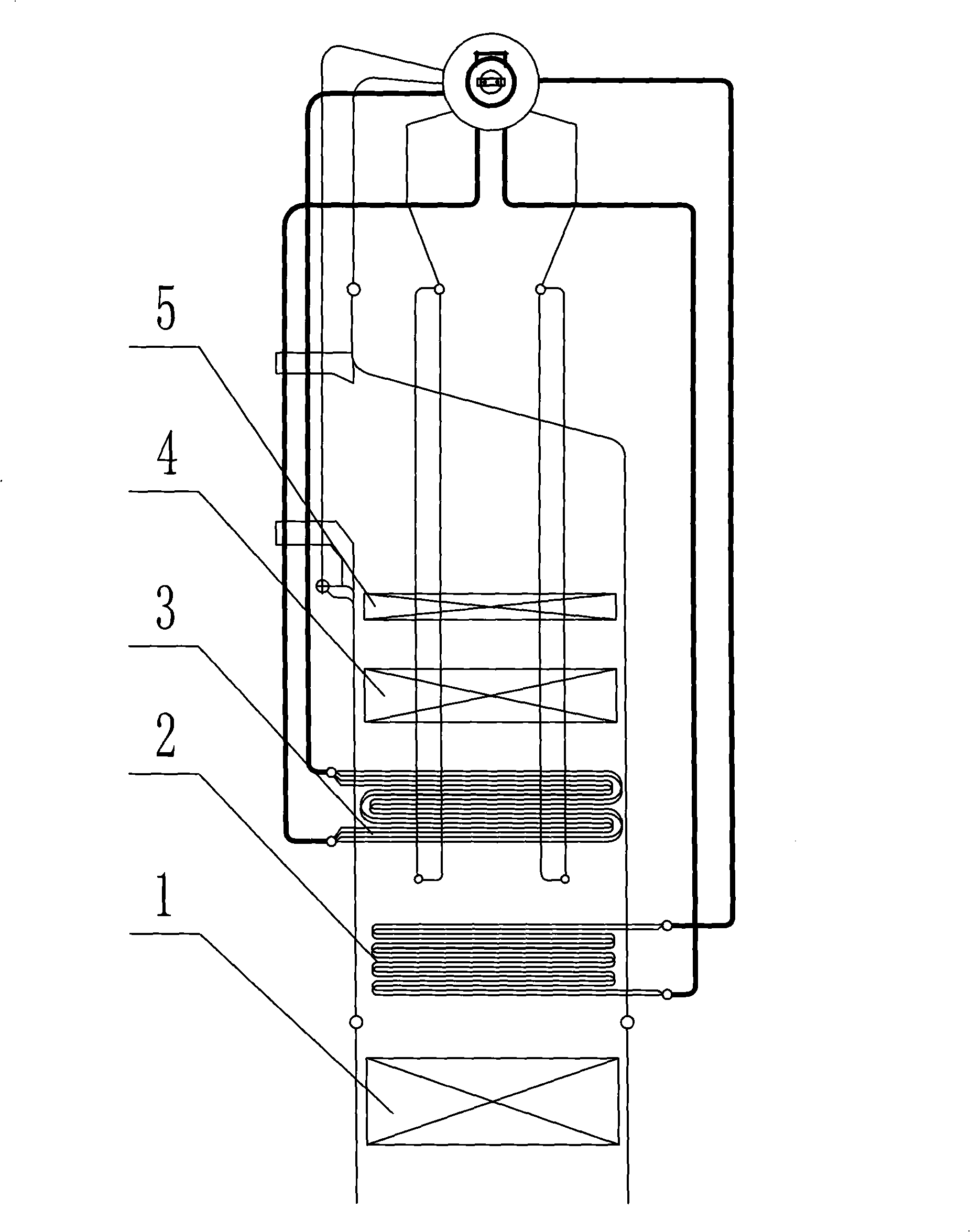

[0009] As shown in Figure 1, each heating surface in the shaft flue of the CDQ waste heat boiler includes: economizer 1, first-stage evaporator 2, second-stage evaporator 3, first-stage superheater 4, and second-stage evaporator Secondary superheater 5. In the present invention, both the first-stage evaporator 2 and the second-stage evaporator 3 are all horizontal tube evaporators with natural circulation, that is, all the tubes constituting the evaporator are parallel to the horizontal plane. In practical applications, the tubes used in the above-mentioned evaporator can be light pipes or finned tubes. For example, the first-stage evaporator 2 can be composed of fin tubes, and the second-stage evaporator 3 can be composed of light tubes. The fully horizontally arranged evaporator is used in the CDQ waste heat boiler, which is more convenient for the layout of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com