Hermetic compressor

A closed compressor and cylinder bore technology, which is applied in compressors, liquid displacement machinery, refrigerators, etc., can solve the problems of low efficiency, reduced volumetric efficiency, increased clearance volume and re-expansion loss of closed compressors And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

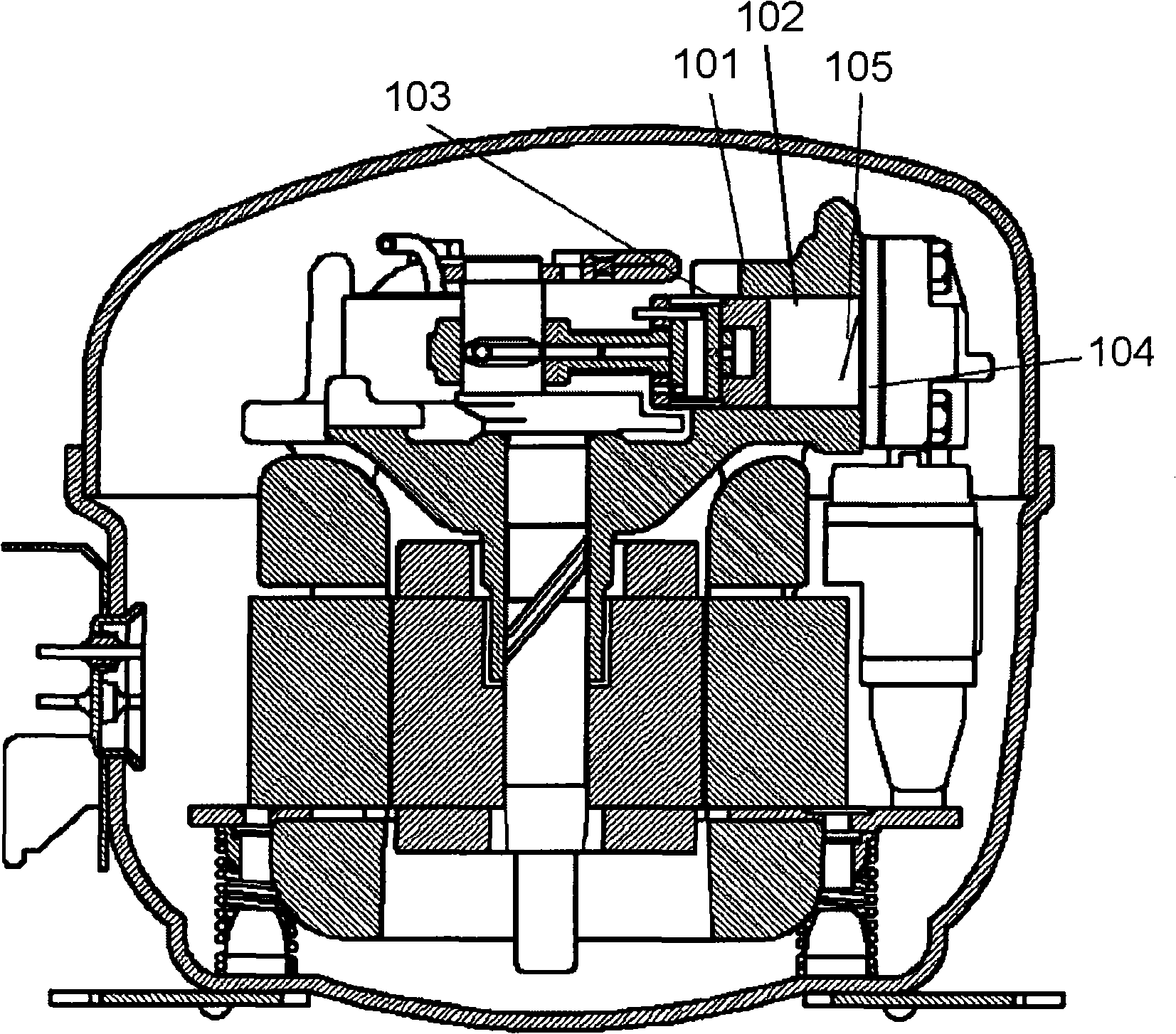

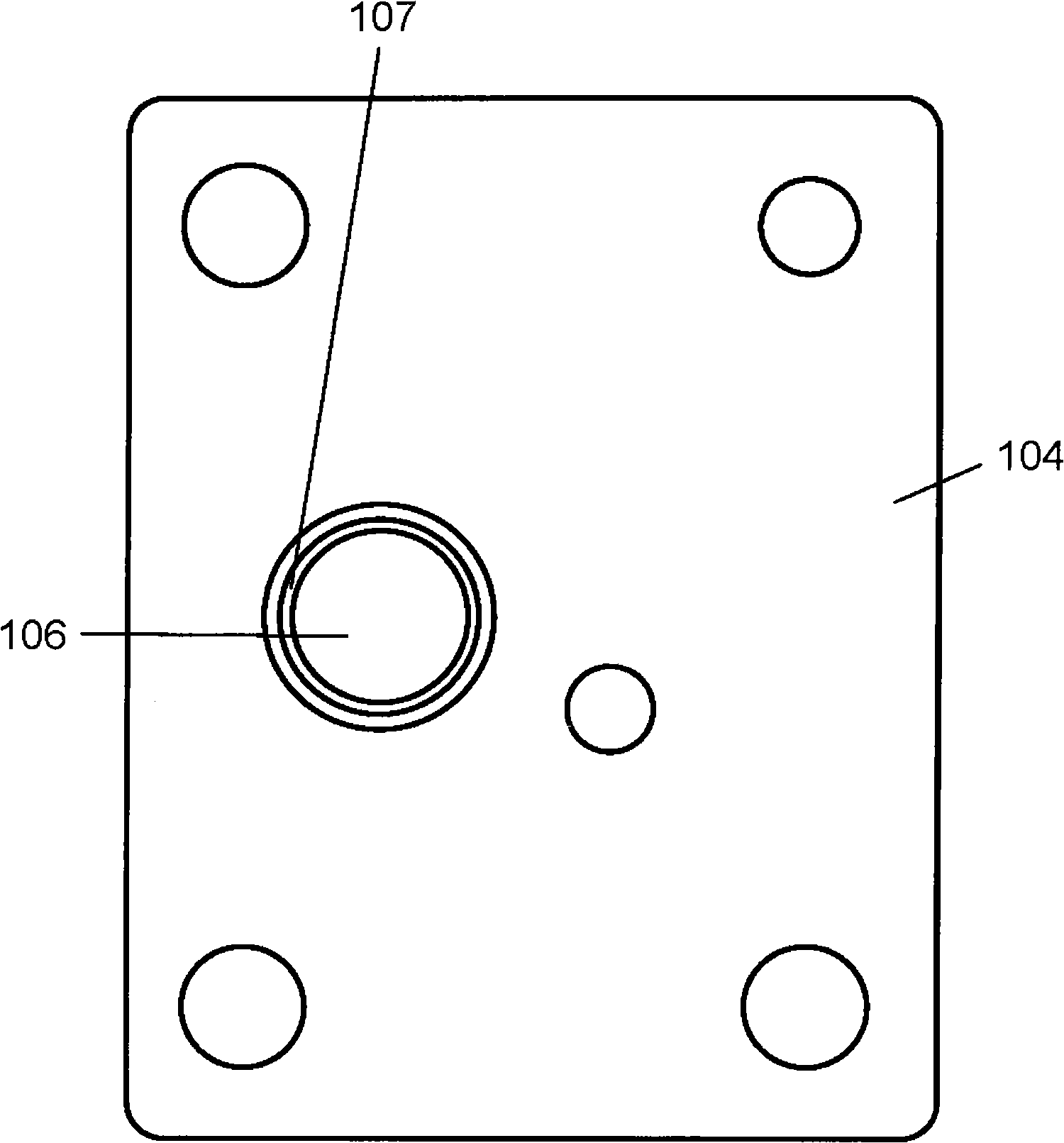

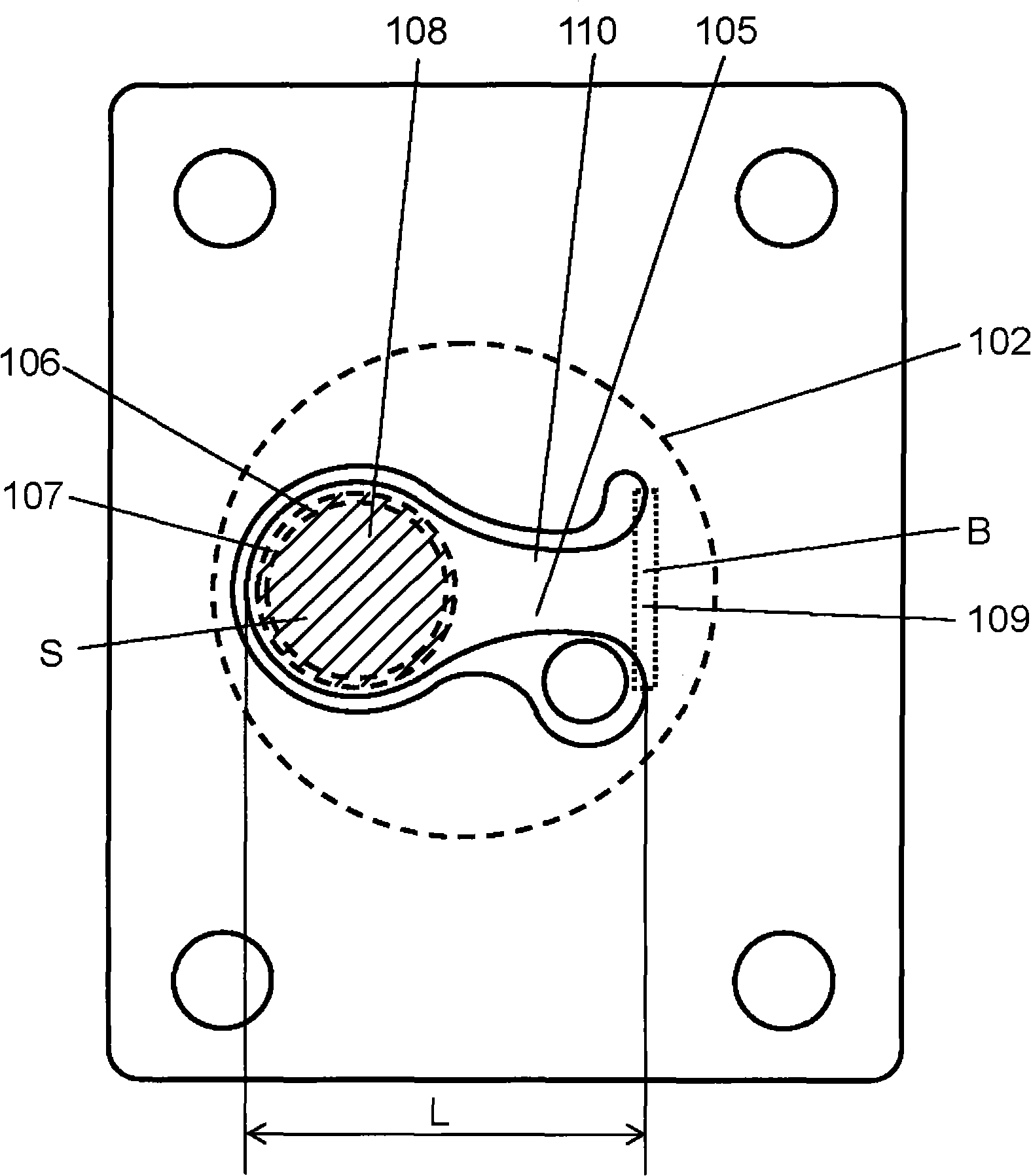

[0024] figure 1 is a sectional view of the hermetic compressor according to the embodiment of the present invention. figure 2 is a schematic diagram of the valve plate of the hermetic compressor. image 3 is a schematic diagram of the suction reed of the hermetic compressor. Figure 4 It is a schematic side view of the suction reed. Figure 5 is a graph showing volumetric efficiency and the ratio of the length between the support end of the suction reed and the end on the opening / closing portion side to the area within the circumference of the suction valve seat of the suction reed. Image 6 It is a graph showing the measurement results of the volumetric efficiency and the area within the circumference of the suction valve seat of the suction reed. Figure 7 It is a graph showing the volumetric efficiency of the hermetic compressor and the measurement results of the length between the support end of the suction reed and the end on the opening / closing portion side.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com