Arrangement method of rotary tillage stubble smashing blade on knife roller

A knife roller and blade technology is applied in the field of the arrangement of rotary tillage blades on the knife roller, which can solve the problems of successive entry of the same direction knives into the soil, and achieve the effects of uniform wear, reduction of axial force, and reduction of shock and vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Whether it is an intermediate drive or a side drive, the cutter roller can be divided into two equal parts, the left half and the right half.

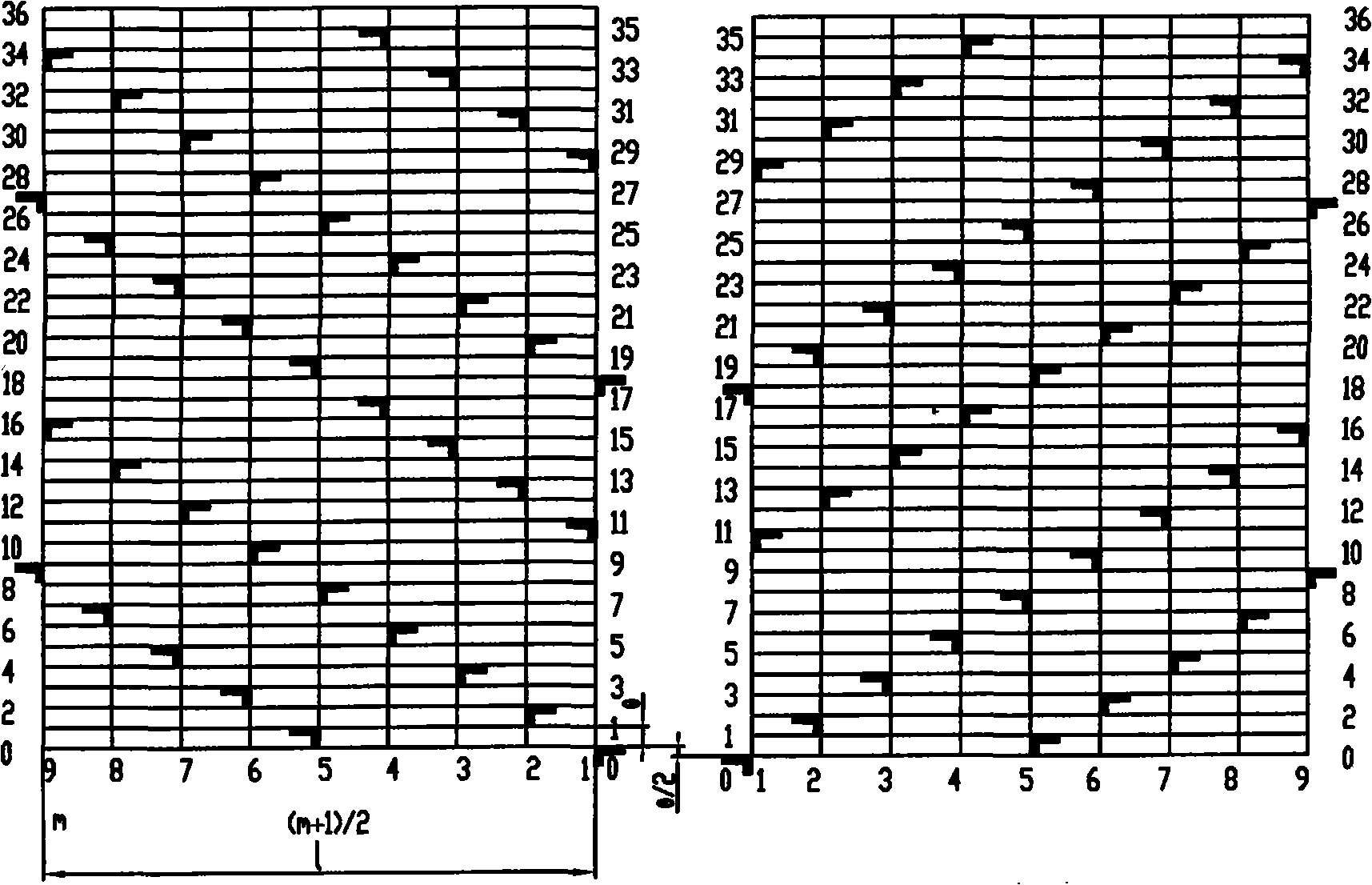

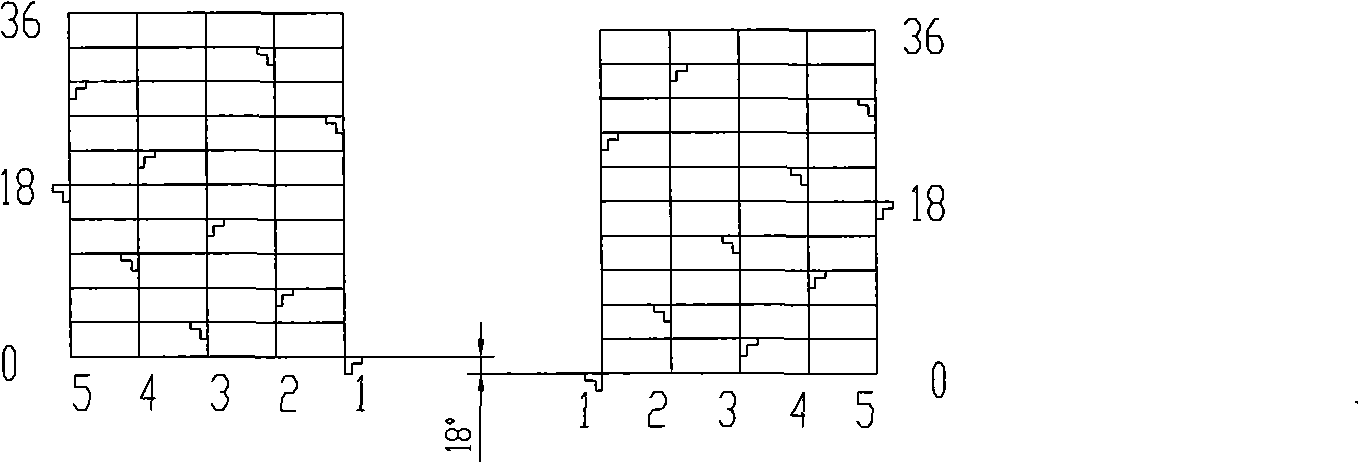

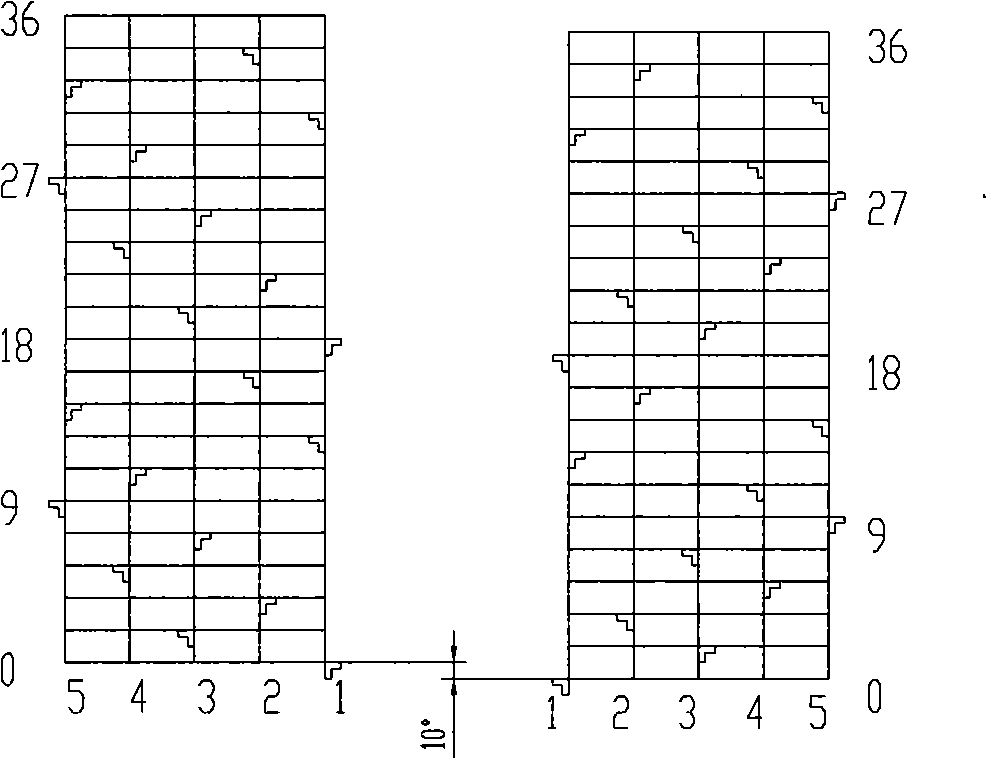

[0026] Combine below figure 1 , taking the intermediate transmission as an example, the present invention will be described in more detail, wherein, figure 1 The arrangement of the blades on the left and right half of the knife roll is shown on the developed view.

[0027] The left half and right half knife rolls are arranged according to the multi-head helix rule respectively. The spiral lines on the left half and right half knife rolls have opposite directions and the same rising angle θ, and the initial phase angle of the two is different. Where N is the total number of blades on the left or right half of the knife roll.

[0028] Referring to the unfolded diagram of the left half-knife roller, the unfolded diagram is also the trace left on the ground when the left half-knife roller rotates for one circle, in which the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com