Method for making golf club head

A technology for golf club heads and manufacturing methods, which is applied to golf balls, golf clubs, manufacturing tools, etc., which can solve the problems of high production costs, long milling processing time, and low processing efficiency, so as to reduce production costs and improve structural strength and reliability, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention, together with the accompanying drawings, are described in detail as follows:

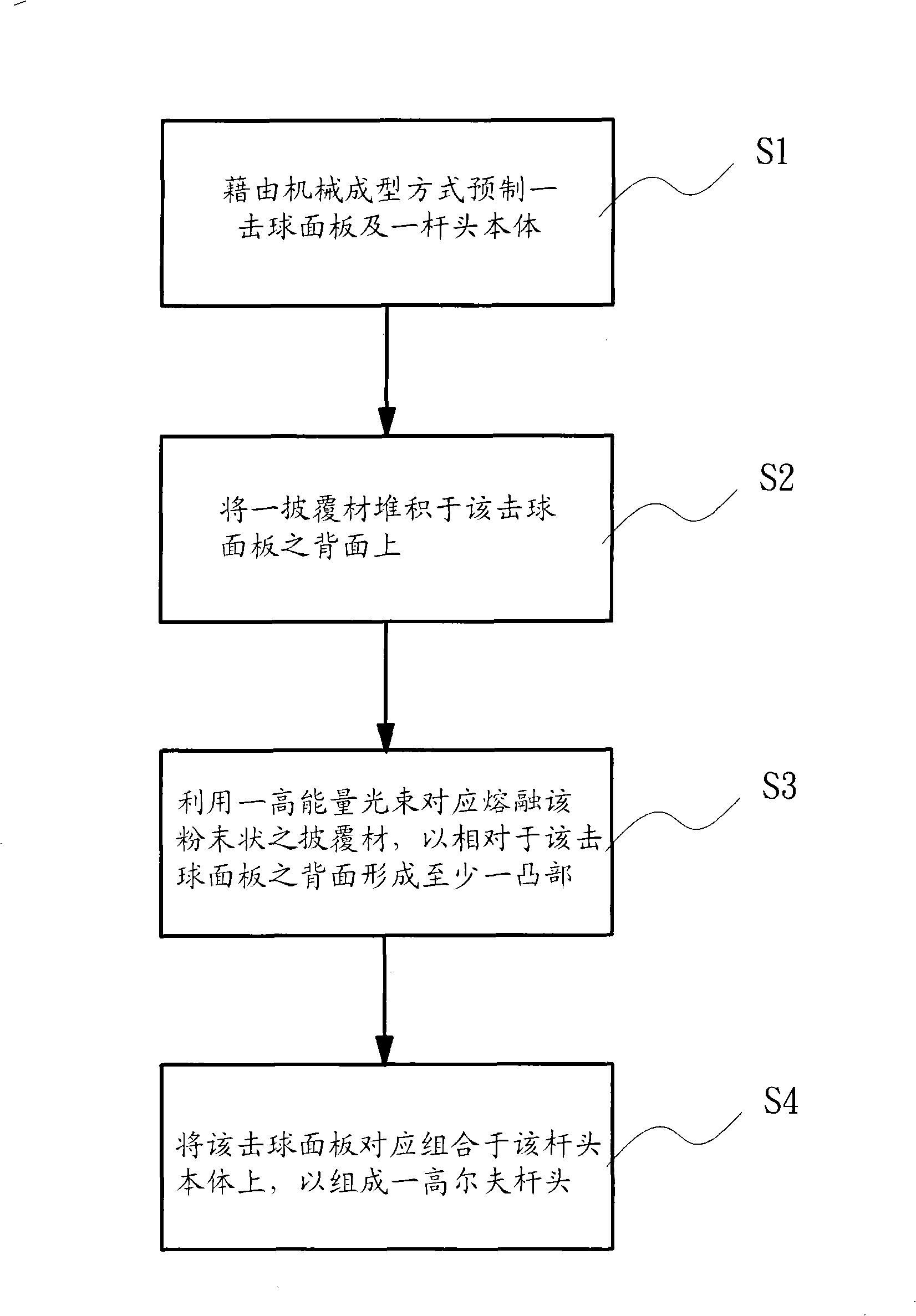

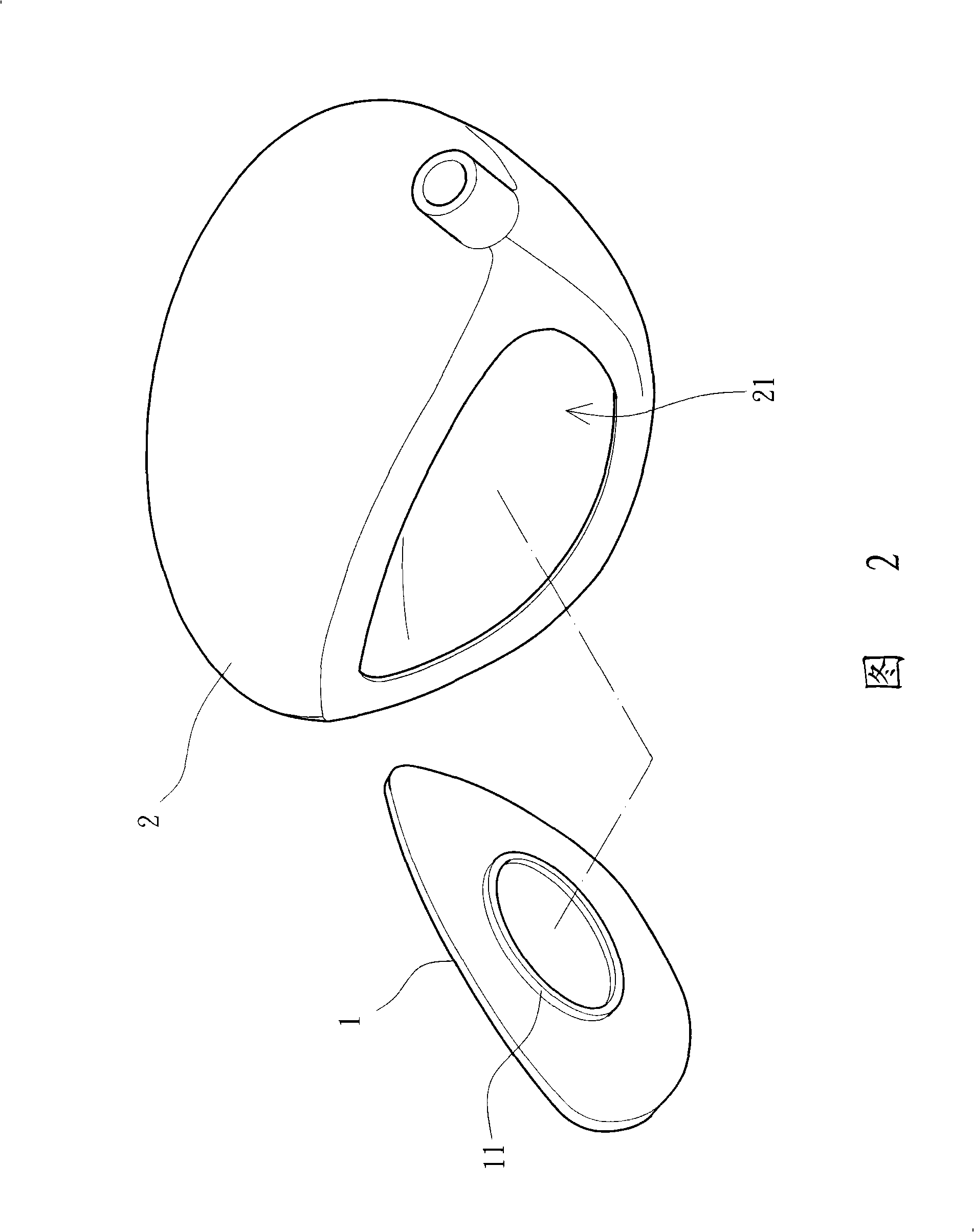

[0015] Please refer to figure 1 As shown in 2, the manufacturing method of the golf club head according to the preferred embodiment of the present invention comprises the following steps: utilizing a mechanical forming method to prefabricate a ball striking panel 1 and a club head body 2; At least one protrusion 11 is formed on the back of the ball hitting panel 1 ; finally, the ball hitting panel 1 is correspondingly assembled on the club head body 2 to form a golf club head.

[0016] please refer again figure 1 As shown in 2, the first step S1 of the manufacturing method of the golf club head according to the preferred embodiment of the present invention: prefabricating the ball striking panel 1 and the club head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com