Electromagnetic valve

A solenoid valve and spool technology, applied in the field of solenoid valves, can solve problems such as inconsistency of fuel injection volume of products, difficulty in adjusting the consistency of solenoid valve air gaps, etc., and achieve reduced induced eddy currents, reduced heat generation, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

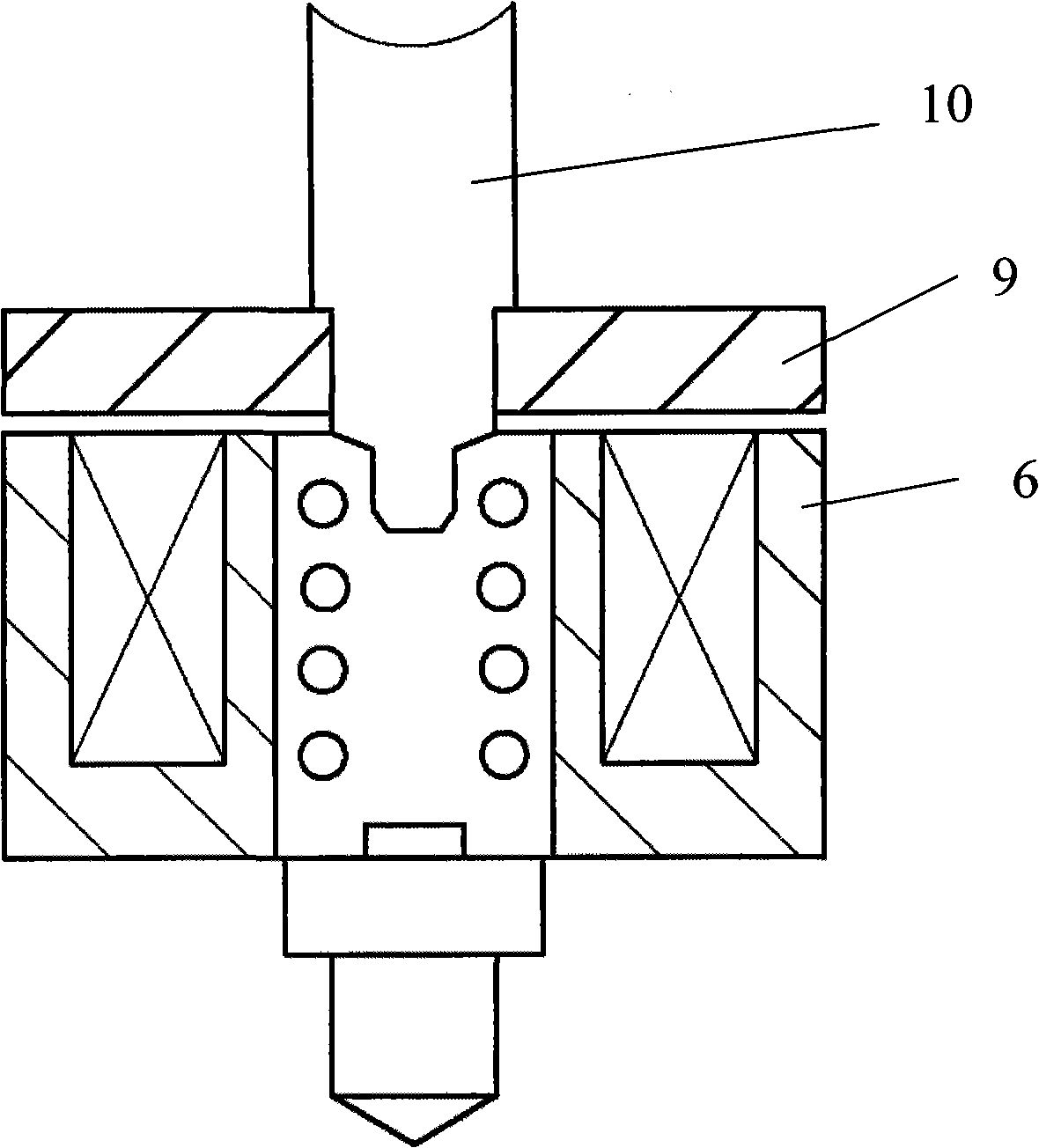

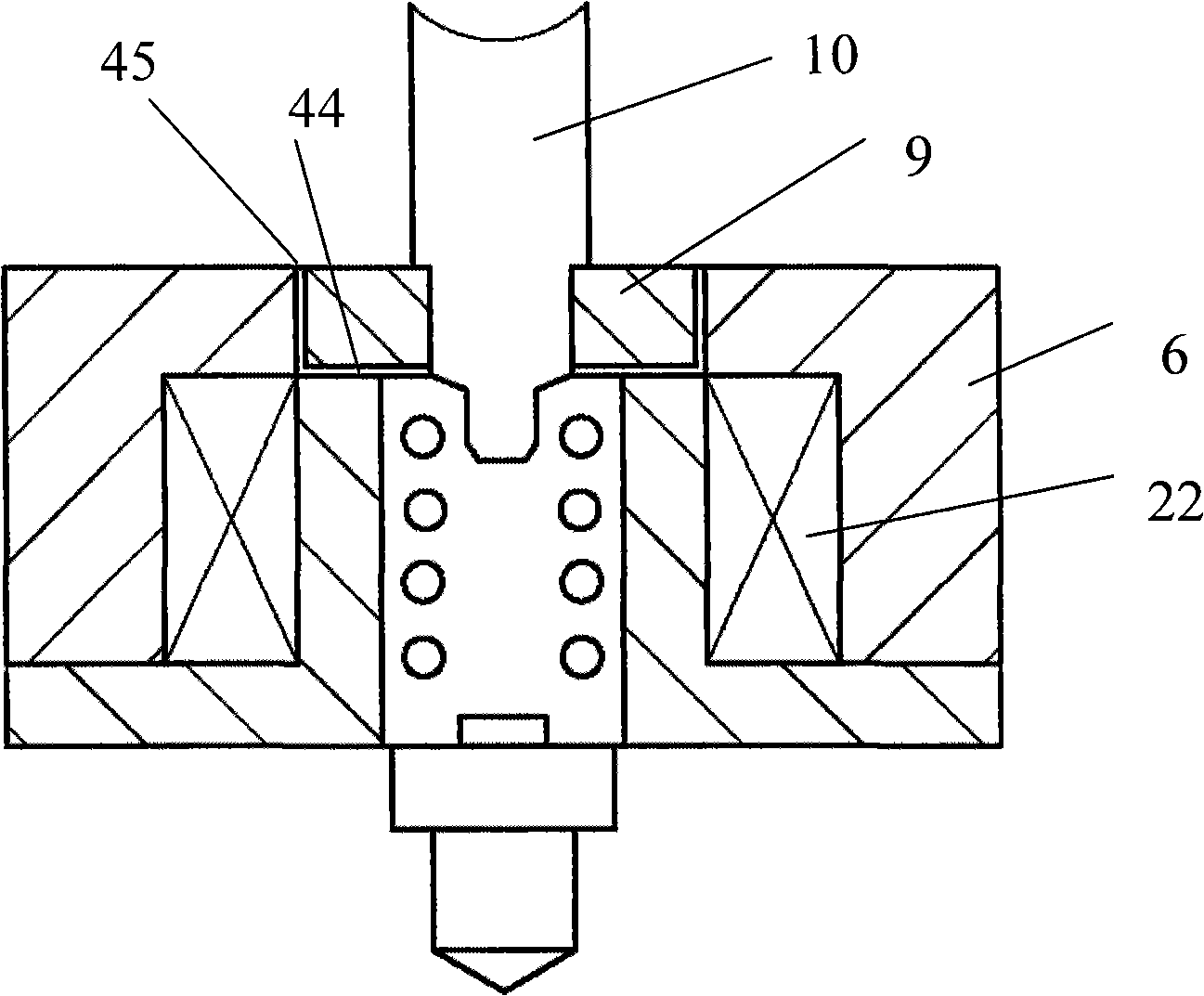

[0028] refer to Figure 8-10 , The solenoid valve of the present invention has a magnetic circuit 25 composed of an iron core 6 , a magnetic ring 8 and an armature 9 . The valve core 10 and the armature 9 are assembled into one body with interference, move together, and are pressurized in the opening direction by the valve spring 7 . The air gap between the armature 9 and the upper surface of the iron core 6 is determined by the axial assembly position of the armature 9 on the valve core 10 .

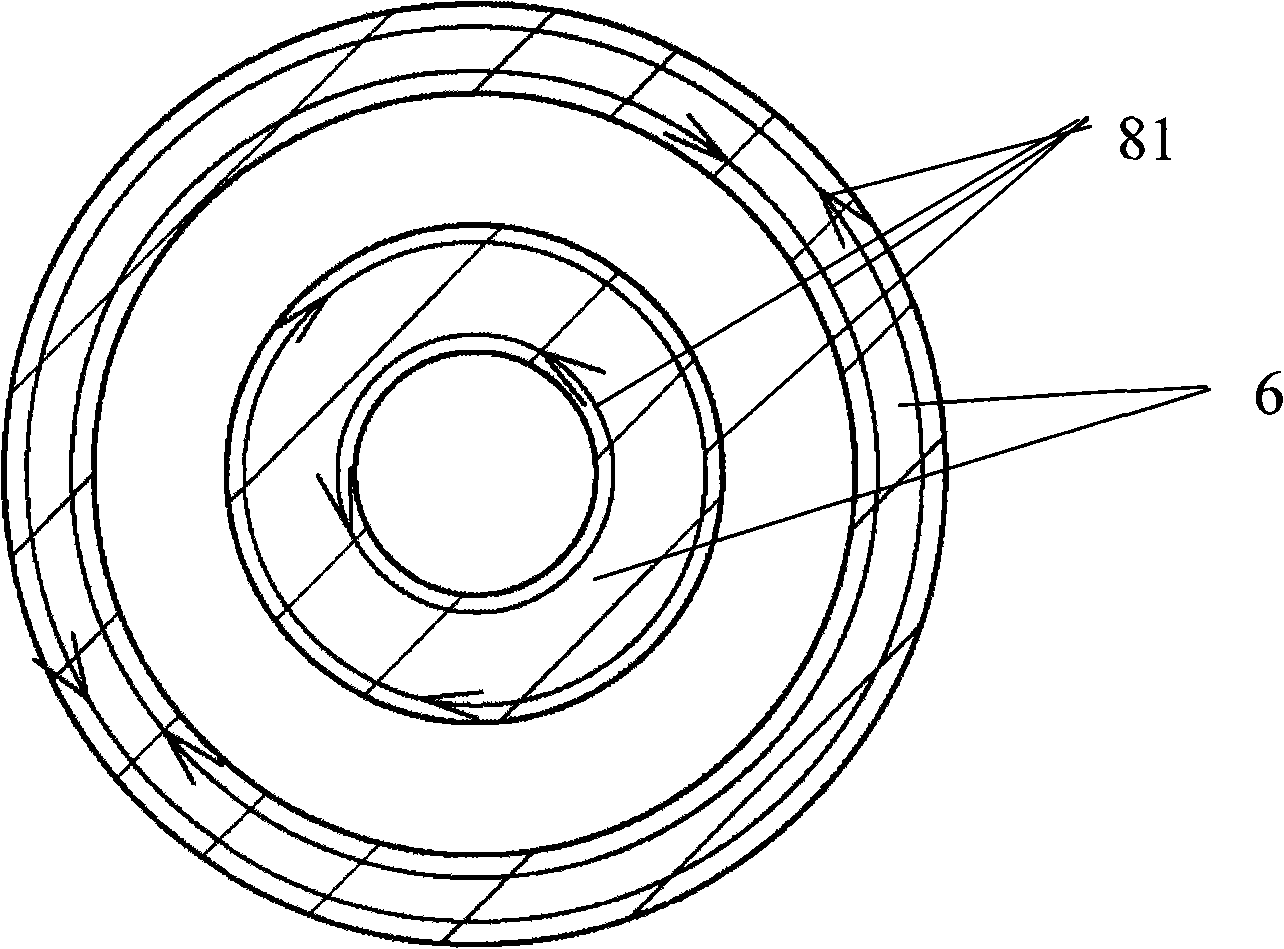

[0029] Such as Figure 8 As shown, the iron core 6 is composed of an electromagnet core 21, a coil winding 22, and a terminal plug 15, and is integrated with potting glue. The electromagnet core 21 is made of solid soft magnetic alloy. Such as Figure 7 As shown, there is a complete gap 91 on one radial side of the electromagnet core 21, and the gap 91 is filled with potting compound.

[0030] Selecting the spring seat 3 with an appropriate installation height ensures that the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com