Valve core replaceable carbon dioxide refrigerating system throttling valve

A carbon dioxide and refrigeration system technology, which is applied in the field of refrigeration system throttling components and carbon dioxide refrigeration system throttle valves, can solve the problems of high manufacturing cost, poor reliability, and inability to effectively adjust the optimal pressure on the high-pressure side, etc., to achieve economical use cost, the effect of widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

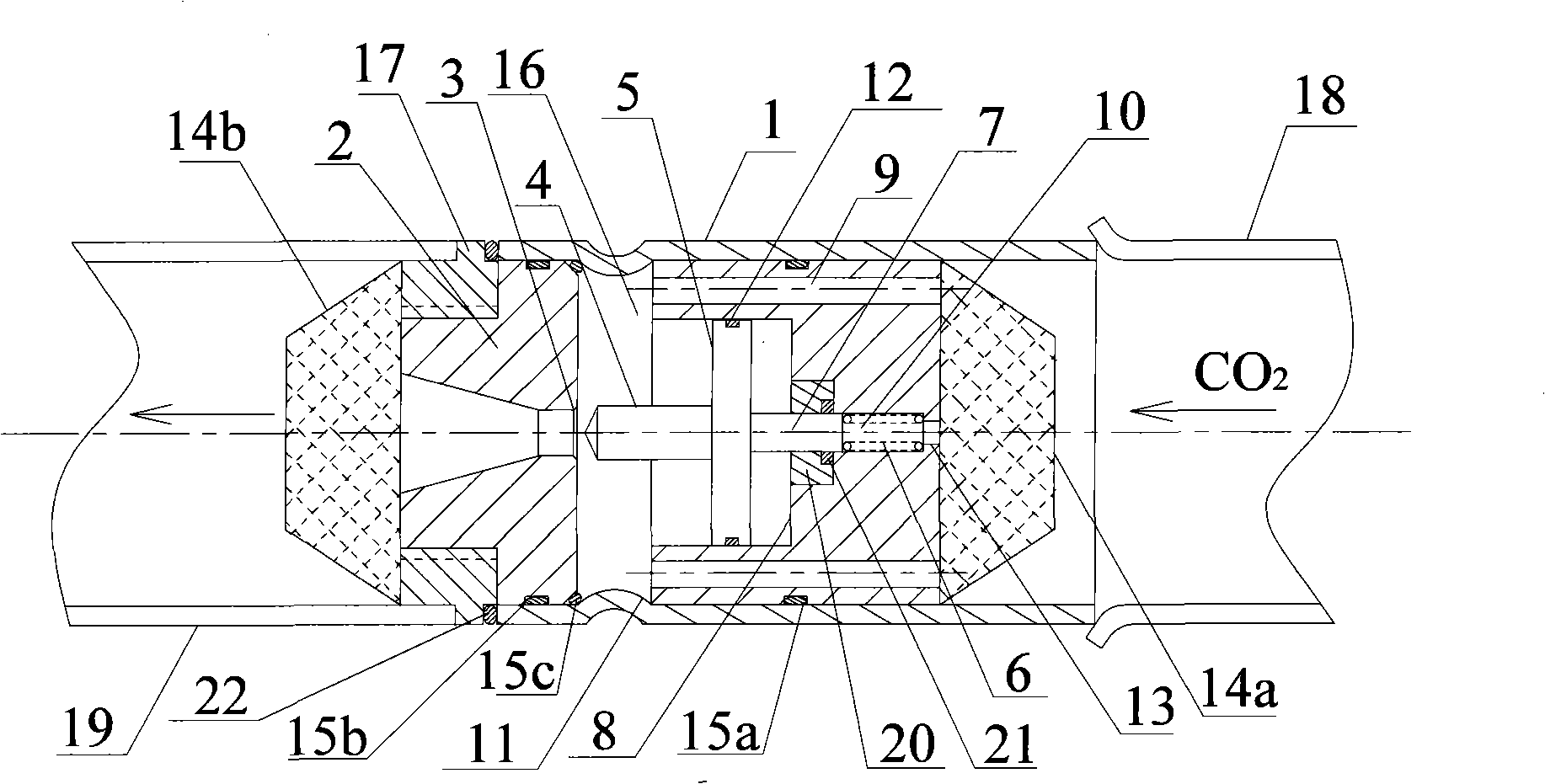

[0017] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

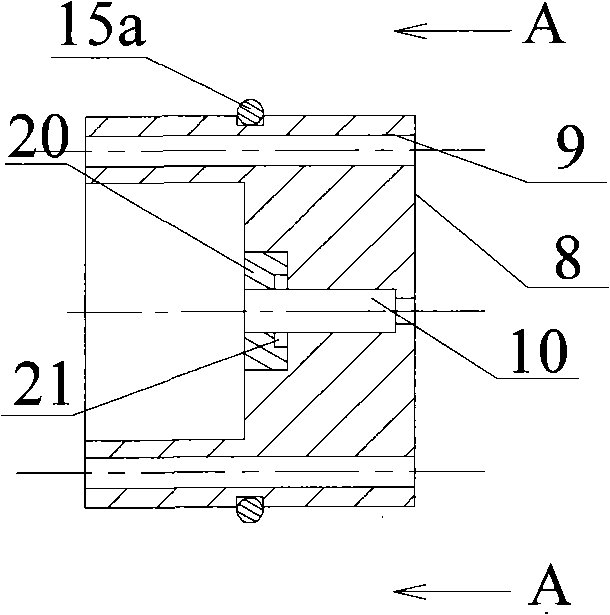

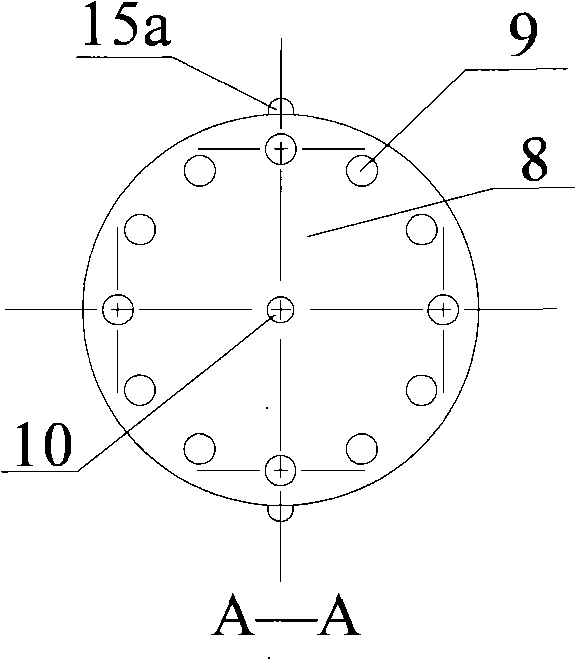

[0018] Such as figure 1 As shown, the present invention includes: casing 1, valve seat 2, valve port 3, valve needle 4, transmission plate 5, memory spring 6, transmission plate connecting rod 7, air intake channel member 8, air intake channel 9, center hole 10. Annular groove 11, air inlet cavity 16, air outlet pipe joint 17, air inlet pipe 18, air outlet pipe 19, sealing block 20.

[0019] An annular groove 11 is formed on the outer circumference by extrusion near the left end of the casing 1, which is used to position the valve seat 2 and the intake passage member 8 at both ends. The entire throttle valve is assembled in a detachable manner. The method is: a third sealing ring 15b is embedded on the outer periphery of the valve seat 2, the valve seat 2 is press-fitted on the inner wall surface of the left end of the casing 1, the valve port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com