Composite anti-counterfeit element

A technology of anti-counterfeiting components and components, which is applied to computer parts, record carriers and instruments used in machines, etc., to achieve high anti-counterfeiting capabilities, convenient and efficient all-round anti-counterfeiting identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

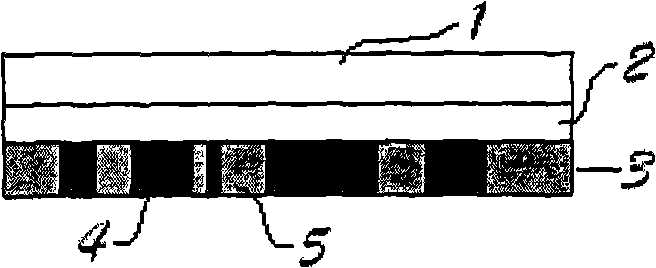

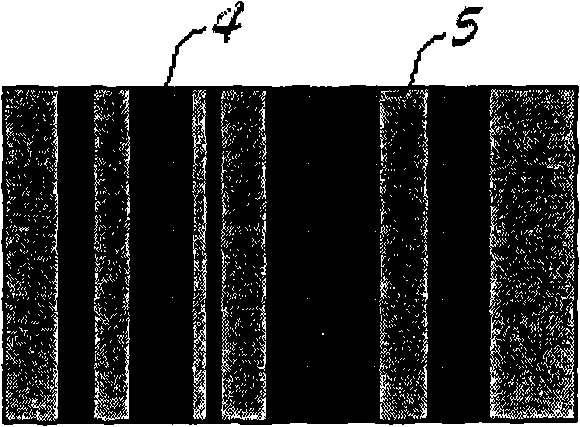

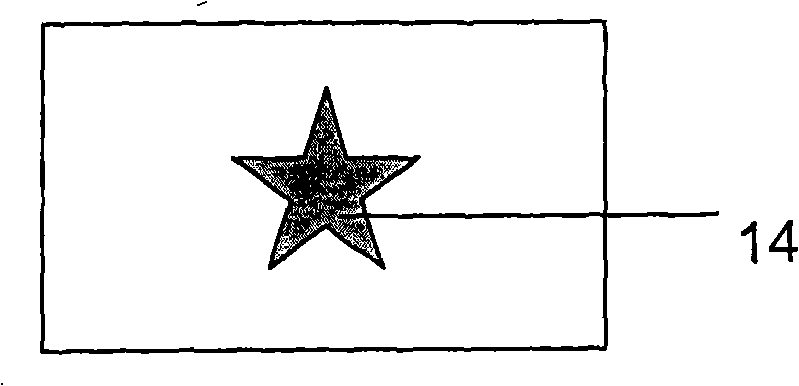

[0049] Utilize the liquid crystal material that ROLIC company produces has the characteristic of discoloration with viewing angle and has hidden positive and negative film pattern by polarizer, forms the liquid crystal layer 1 that has two-layer structure on one side of PET base material 2 according to known method, makes liquid crystal layer Invisible image 14 (see Figure 1-3 ), printed dark Fe on the other side of the PET substrate by gravure 3 o 4 Magnetic ink 4 and overprint dark common carbon black ink 5 on the face of this PET base material, constitute coding layer 3 on this face of base material, as Figure 1-2 As shown, the encoding layers are arranged in a manner similar to commercial barcodes. For the setting of the three-layer structure of the composite element, please refer to Picture 1-1 , wherein both the liquid crystal layer 1 and the substrate 2 are transparent, and the colors of the magnetic material 4 and the carbon black 5 constituting the encoding layer...

Embodiment 2

[0052] Utilize the liquid crystal material (same as embodiment 1) that ROLIC company produces with the color-changing characteristics with the angle of observation and has a hidden positive and negative film pattern by means of a polarizer, form a liquid crystal layer 1 on one side of the BOPP transparent substrate 2 according to known methods, A latent image is formed in the liquid crystal layer. On the other side of the BOPP (biaxially oriented polypropylene) base material, print dark or light-colored infrared absorbing ink 6 and dark-colored infrared reflective material 7 to apply paired codes. The application method is to first print the infrared absorbing material 6 on the set area on the surface of the substrate, and then print the infrared reflecting material 7 on the entire area of the substrate surface to make the side surface such as figure 2 Composite elements shown.

[0053] The liquid crystal layer of the composite element is observed at different angles. When...

Embodiment 3

[0055] Using the liquid crystal material ROLICURETM produced by ROLIC TM PEARL 1 On one side of a transparent PET substrate or aluminized film substrate 2, an image is formed in the liquid crystal layer, and dark Fe is printed on the other side of the substrate 3 o 4 Magnetic ink 4 and NiZn ferrite ink 5 of dark soft magnetic material are overprinted to form soft and hard magnetic characteristic coding layer 3 . The side effects of this composite element are as follows image 3 shown.

[0056] The coding arrangement of the formed composite components is the same as Figure 1-2 Similarly, when the composite anti-counterfeiting element is rotated, the image of the liquid crystal layer changes from a positive film to a negative film. The distribution of soft and hard magnetic materials can be read out under a special magnetic detection instrument. Distinguish the different characteristics of soft magnetic and hard magnetic materials to achieve the purpose of verifying the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com