Intelligent charge control method for Ni-MH power accumulator set

A power battery and intelligent charging technology, which is applied to battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of late capacity decline, long charging time, and impact on battery life, so as to avoid battery performance and life, and improve charging Efficiency and the effect of shortening the charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

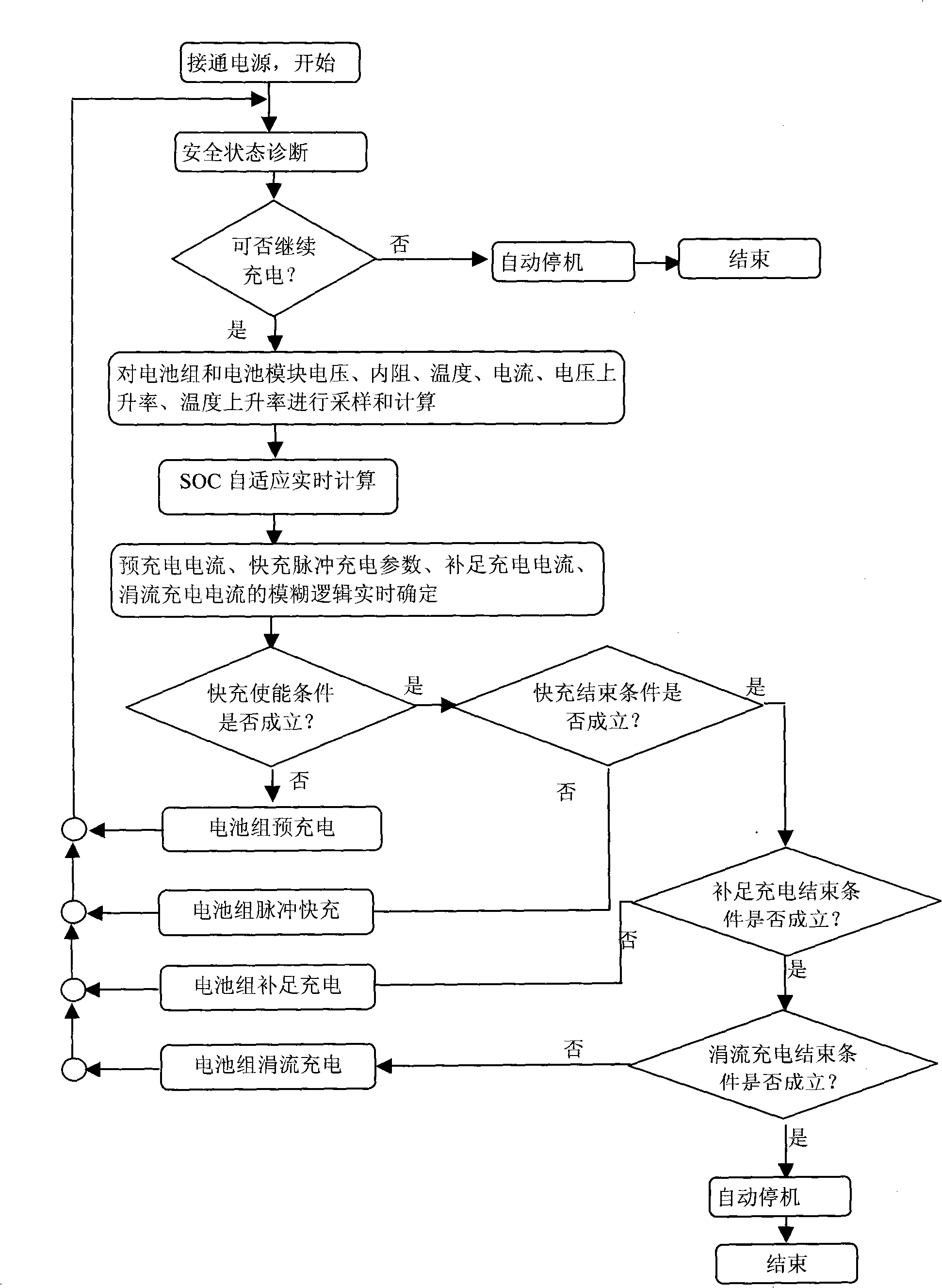

[0008] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the Ni-MH battery pack intelligent charging control method of the present invention is specifically implemented in the following manner and steps:

[0009] (1) Turn on the power, and the charger is ready to start.

[0010] (2) Apply charging and discharging current pulses to the rechargeable battery pack, sample the current, module voltage, and battery pack voltage synchronously in an event-triggered manner, automatically calculate the internal resistance of the battery pack and battery module, and automatically calculate the initial SOC of the battery charge in combination with the voltage and temperature value, automatically diagnose the initial state of the battery, and determine the pre-charge current.

[0011] (3) If the pre-charging enabling condition is established, the battery pack is charged with the pre-charging current, and the battery pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com