Self-help service plate cleaning machine

A cleaning machine and self-service technology, which is applied in the direction of tableware washing machine/rinsing machine, cleaning equipment, household cleaning device, etc. It can solve the problem of affecting the dining hygiene and the appearance of the canteen, and can not solve the messy dining table and the heavy workload of the cleaners. and other issues to achieve the effect of saving operating costs, simple structure and good connection

Inactive Publication Date: 2011-01-05

HUNAN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The dishwasher with this structure can achieve the purpose of cleaning the dishes and dishes and sterilizing them, but in order to reduce the water and electricity consumed in the dishwashing process, reduce the cost of cleaning the dishes, and reduce the retention of garbage in the machine, To improve the cleaning effect, before the dishes enter the machine, it is necessary to collect the dishes and initially dump or brush the residue on the dishes. At present, this preliminary auxiliary process is completed manually. This large-scale fully automatic dishwashing The cabinet can't solve the messy problem of the dining table

Therefore, when eating in the canteen, you can often see the messy phenomenon of the dining table, especially during the peak dining period, due to the lack of manpower, the uncleaned plates are piled up, which not only affects the dining hygiene and the appearance of the canteen, but also the work of the cleaners. The amount is also quite heavy and laborious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

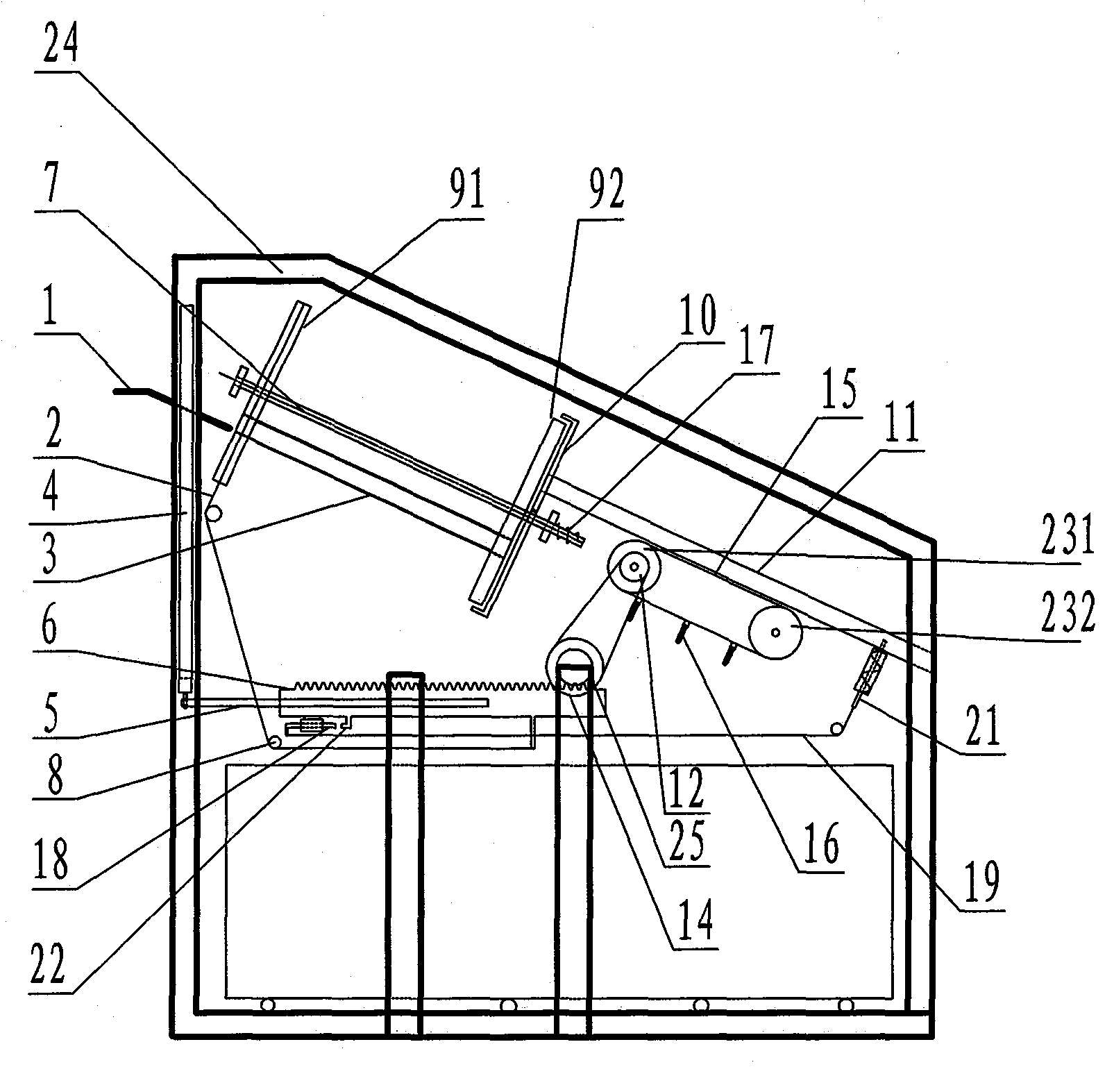

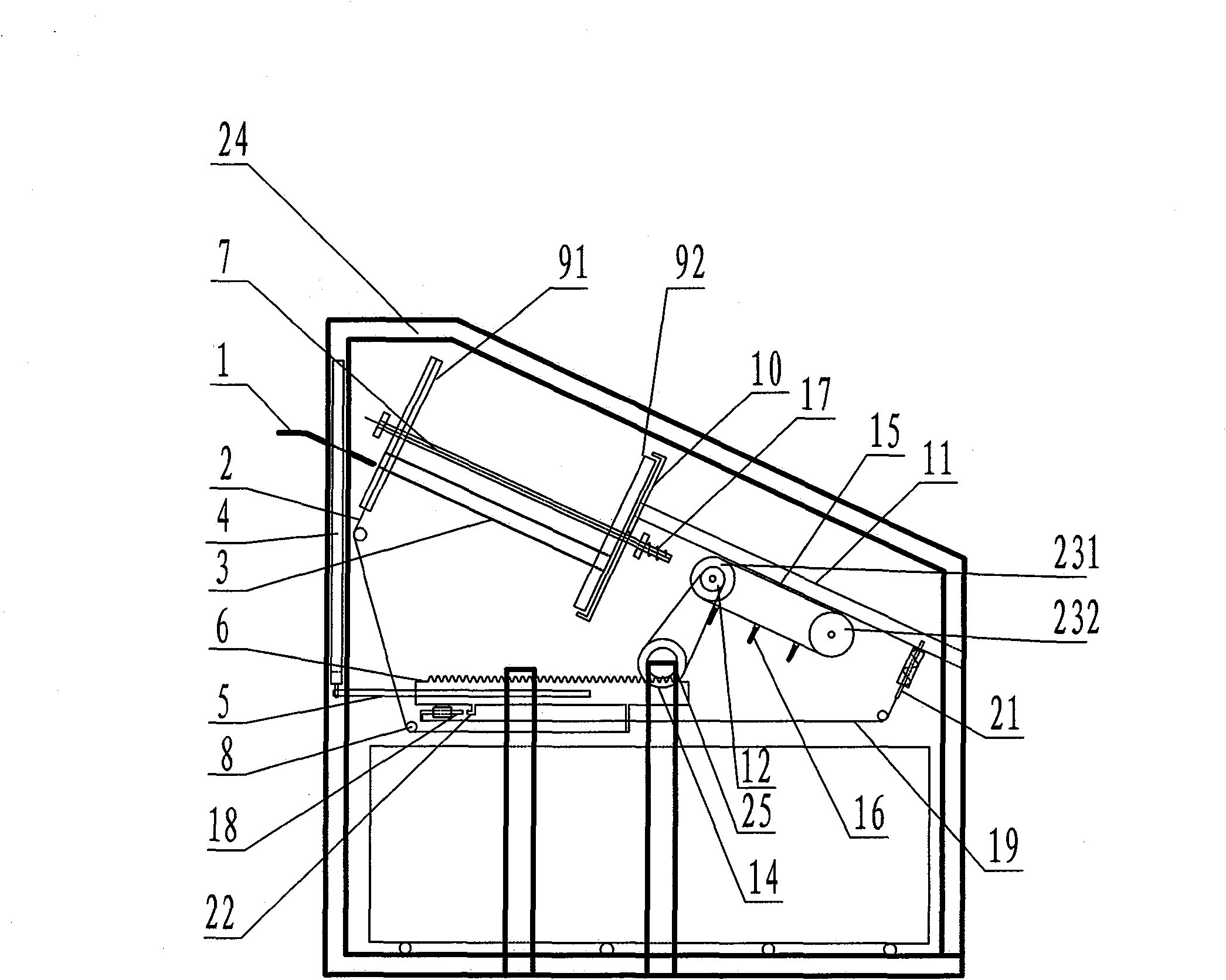

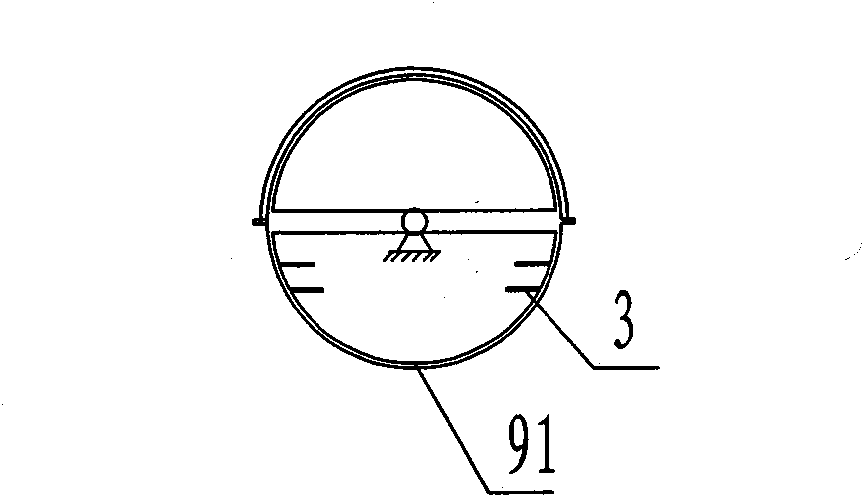

The invention relates to a self-service type plate cleaning machine which comprises a machine frame, a plate clearing device arranged on the machine frame and a power device driving the plate clearing device to work. The plate clearing device comprises a plate entrance, a first rail, a swivel, a rotating rod, a spiral spring, a baffle, a second rail and a brush device; the power device comprises a rack, a transmission device, a cable pulley mechanism, a sliding door, a movable sliding rod and a spring prop; the brush device comprises two tumbling boxes and a cranked link chain with a brush isarranged between the two tumbling boxes; a first sprocket wheel is installed on one of the tumbling boxes; the plate cleaning machine has the advantages of simple structure, convenient use and does not need electricity, thus a power system is not needed; further more, the manufacturing cost is low and no noise is produced during operation. Therefore, the machine can be used in canteens for partially replacing manual labor and has high man-machine safety and the operation cost can be reduced. In addition, the machine is applicable to large, medium and small canteens.

Description

Self-service plate cleaner technical field The invention relates to a dish cleaning machine, in particular to a self-service dish cleaning machine. Background technique The working process of the current commercial large-scale automatic dishwashing cabinet is generally: place the tableware on the tableware rack in the dishwashing cabinet, and then use the impact of water to remove the dirt, which is generally divided into two stages: 1. Washing: recycle 50 -60°C Rinse dishes with warm water with detergent to remove dirt and grease. 2. Spray: Wash the tableware with water above 82 degrees to achieve cleaning and disinfection. Then, use quick-drying agent or hot air to dry and disinfect the tableware to destroy the conditions for bacterial reproduction. The dishwasher with this structure can achieve the purpose of cleaning the dishes and dishes and sterilizing them, but in order to reduce the water and electricity consumed in the dishwashing process, reduce the cost of clea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A47L15/39

Inventor 唐守德赵威刘江南胡芳

Owner HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com