Intelligent Plug-in containing case special for small cards and uses thereof

A technology for small cards and material storage, applied in the field of smart card manufacturing equipment, can solve the problems of easy scattering due to careless operation, slow processing speed and high processing cost, and achieve the effects of easy arrangement and cleaning, increased production speed and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

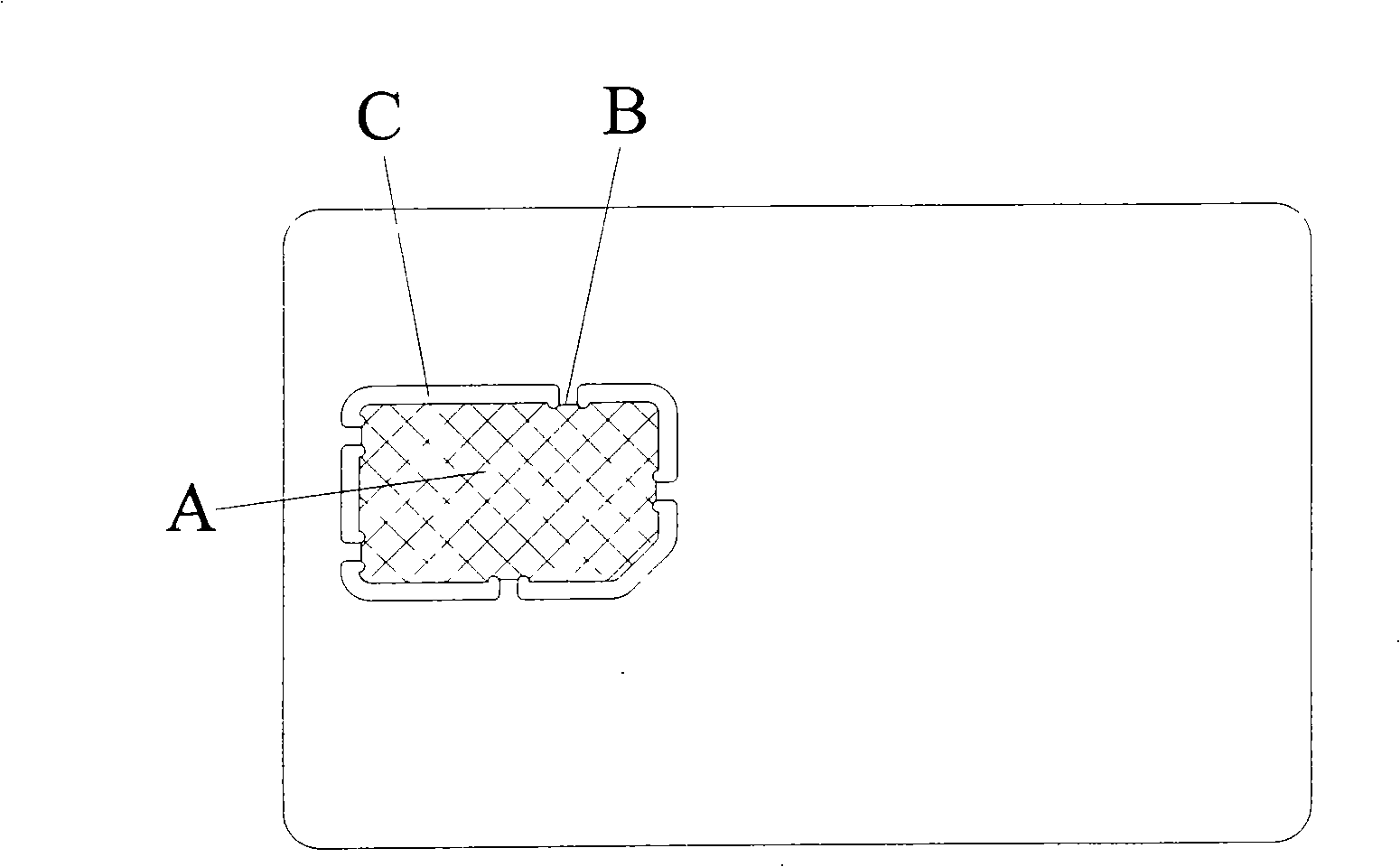

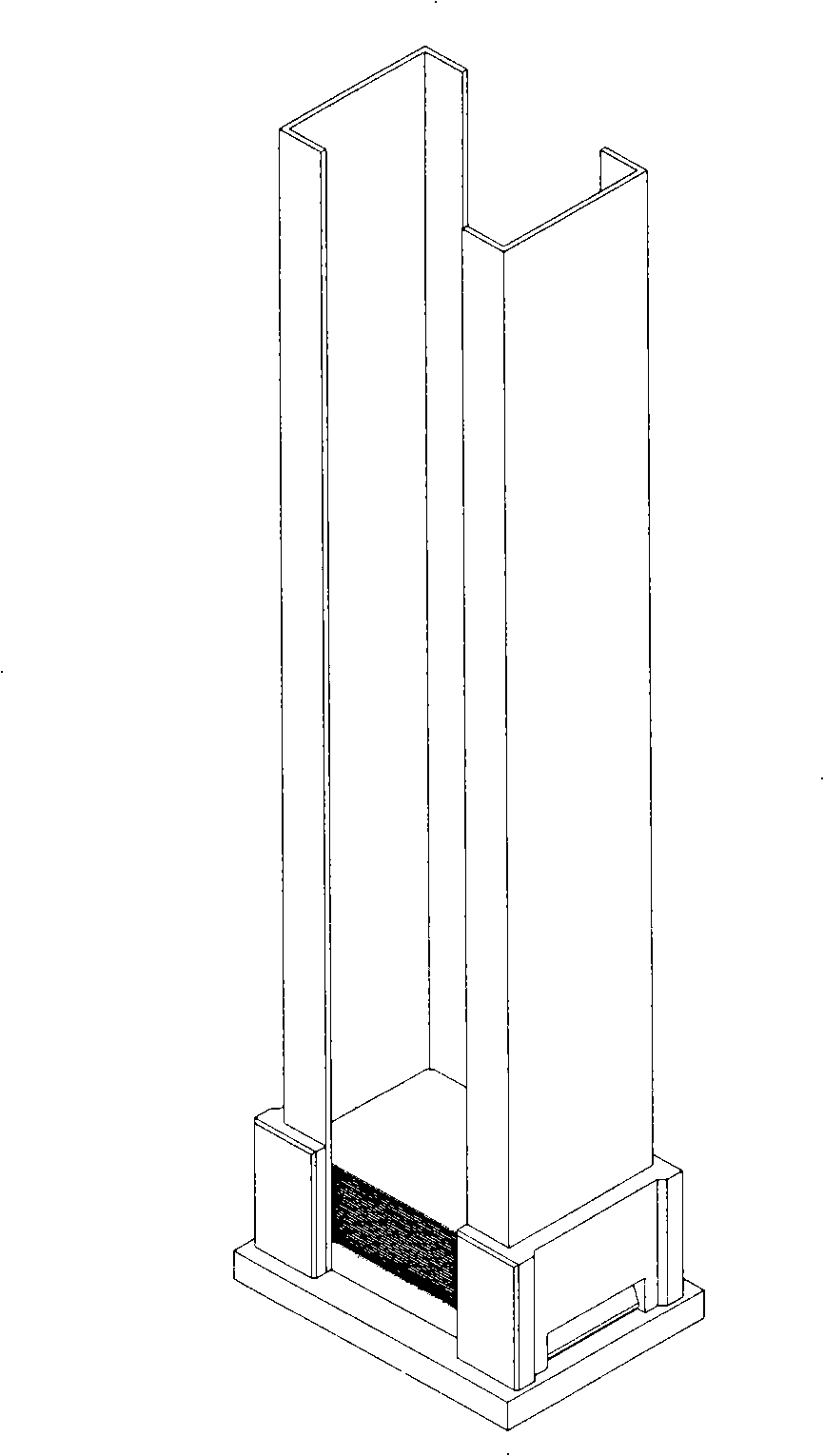

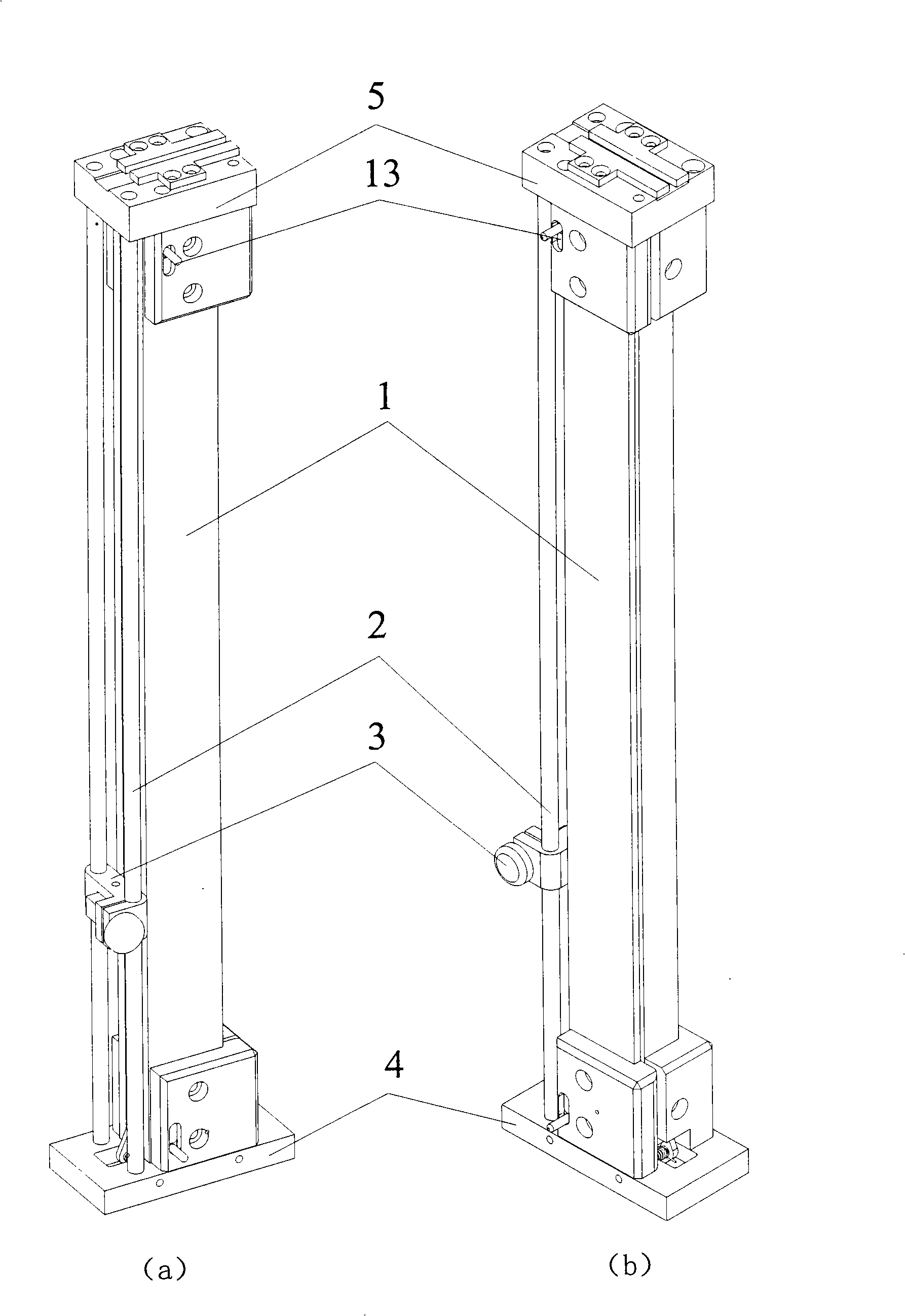

[0035] Figure 3 ~ Figure 5 A specific structure of the present invention is shown, by image 3 It can be seen that the special storage box for smart Plug-in small cards includes a card storage tank 1 and a sliding pressing mechanism. , the cross-sectional size of the card storage tank 1 is greater than the plane size of the Plug-in small card, and the gap between the inner wall of the card storage tank 1 and the periphery of the built-in Plug-in small card is not greater than 0.25 to 0.5 mm; to avoid The small plug-in card has a relatively large virtual position in the storage card slot and moves or flips; the sliding pressing mechanism includes a sliding support rod 2 and a slider 3, and the sliding support rod 2 is arranged in parallel with the storage card slot body 1, The two ends of the card storage tank body 1 are respectively provided with a card receiving base plate 4 and a card issuing base plate 5, and the two ends of the sliding support rod 2 are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com