Constant-voltage electroanalysis water making apparatus and method

A technology for a water production device and an electrolysis device, which is applied in chemical instruments and methods, water/sewage treatment, non-polluted water treatment, etc., can solve the problems of difficulty in mass production and difficulty in ionizing water machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

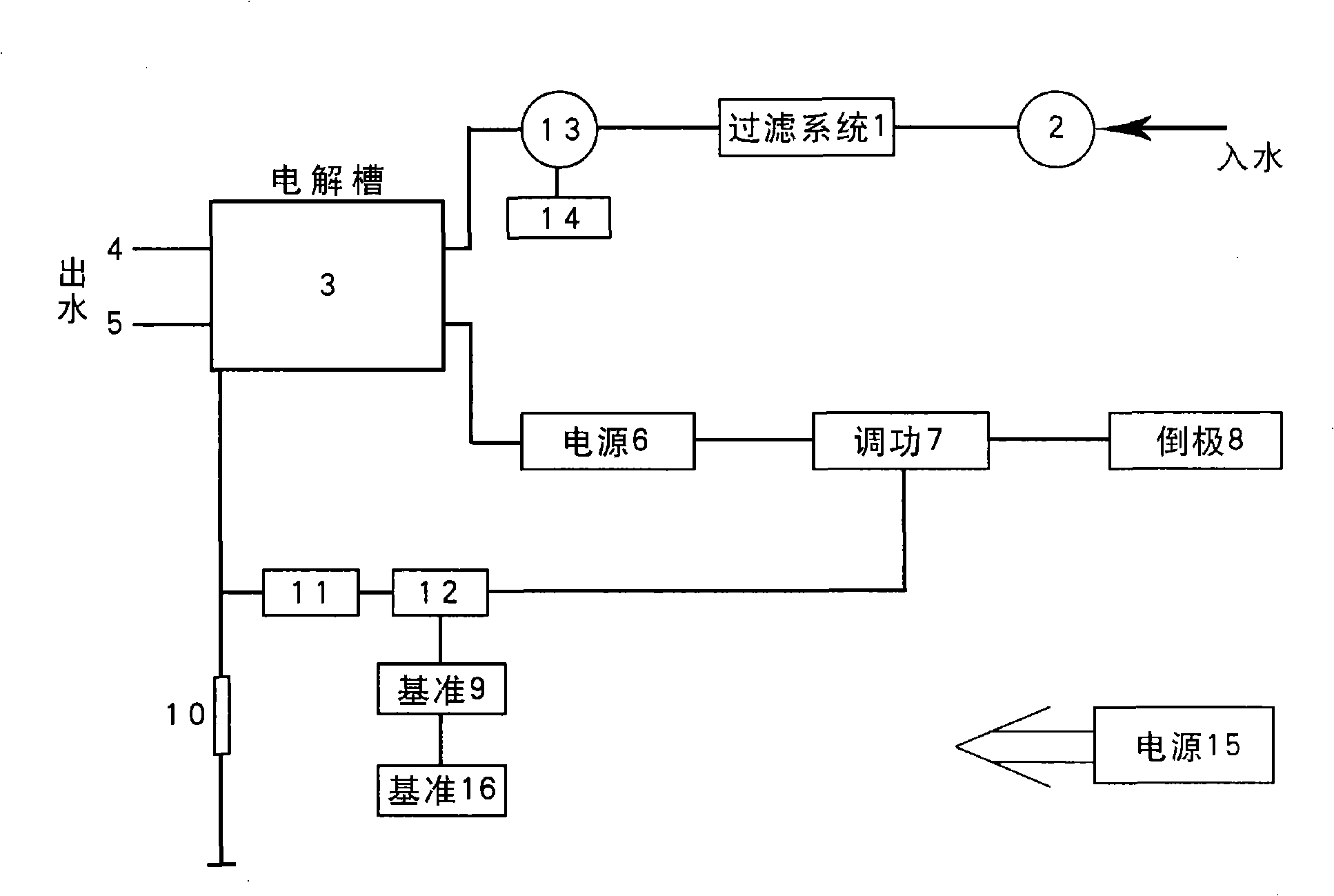

[0025] Such as figure 1 As shown, the circuit structure according to the present invention includes an electrolytic cell 10, an electrolytic cell electrolysis voltage error sampling circuit unit 20, a comparison operation circuit unit 30, a pulse width modulation circuit unit 40 and a control circuit unit 50, the above-mentioned electrolytic device 10 and each circuit unit Through the sequential connection of wires, one end of the connecting wire of the reference switching unit 60 is connected to the connecting wire between the electrolysis voltage error sampling circuit unit 20 and the comparison operation circuit unit 30 of the electrolyzer.

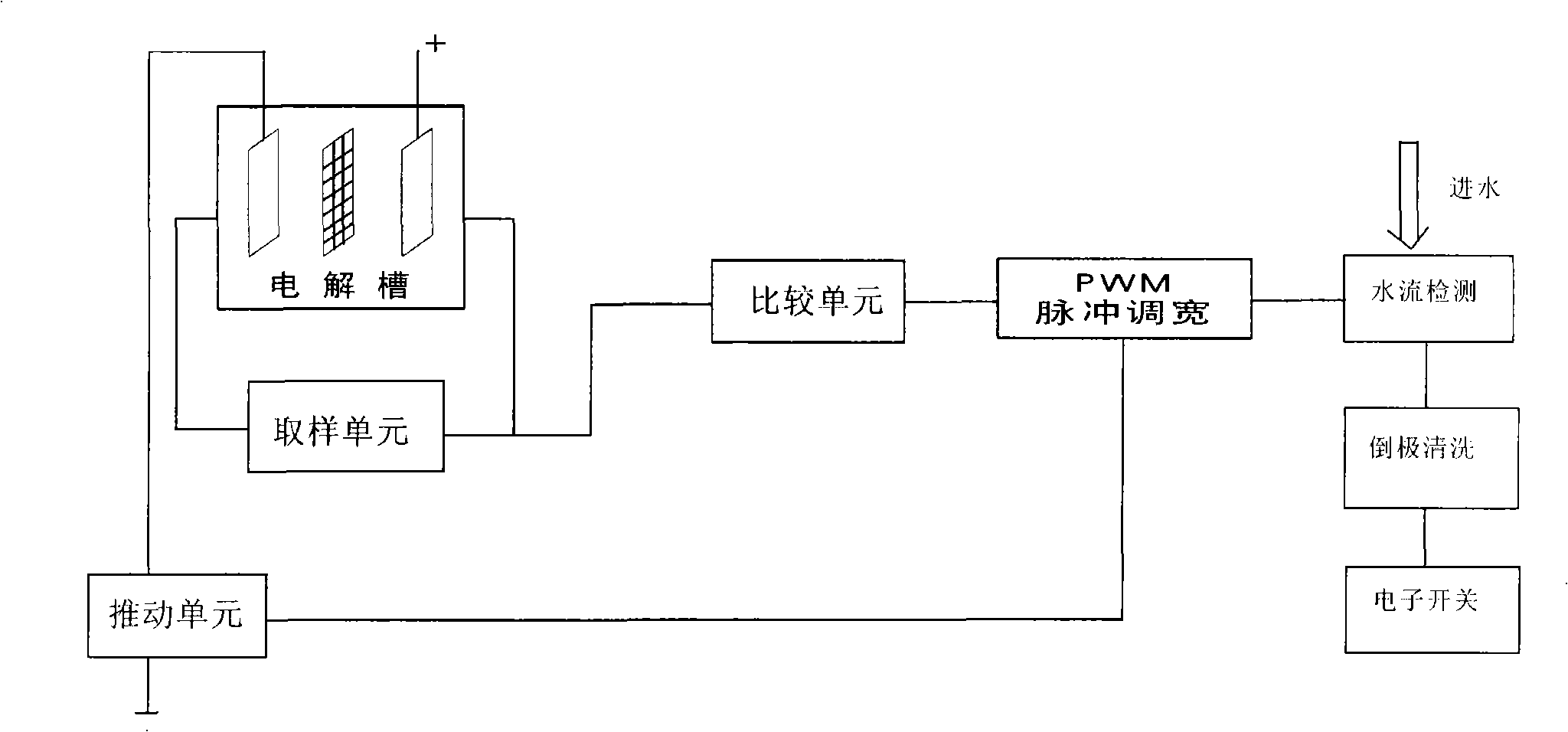

[0026] figure 2 It is a circuit structure according to an embodiment of the present invention. A constant voltage is applied to the electrolytic cell. Due to the existence of electrical conductivity in water, current flows through both ends of the electrode plate. When the current flows through the electrolytic device, the control cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com