Zirconium kalium phosphate type high temperature purple ceramic pigment and preparation method

A technology of ceramic pigment and potassium zirconium phosphate, which is applied in the field of high temperature purple ceramic pigment of zirconium potassium phosphate and its preparation, can solve the problems such as rare, unstable crystal structure of pigment, few pigments, etc. The effect of bright color and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The raw materials are prepared according to the weight percentages in the table below, the calcining temperature is 1400° C., the temperature is kept for 60 minutes, and the obtained product is pulverized, washed, dried, pulverized and dried.

Embodiment 2

[0013] The raw materials are prepared according to the weight percentages in the table below, the calcining temperature is 1400° C., the temperature is kept for 60 minutes, and the obtained product is pulverized, washed, dried, pulverized and dried.

Embodiment 3

[0016] The raw materials are prepared according to the weight percentages in the table below, the calcining temperature is 1400° C., the temperature is kept for 60 minutes, and the obtained product is pulverized, washed, dried, pulverized and dried.

[0017] potassium carbonate

diammonium hydrogen phosphate

Zirconia

7.6

53.2

36.6

2.6

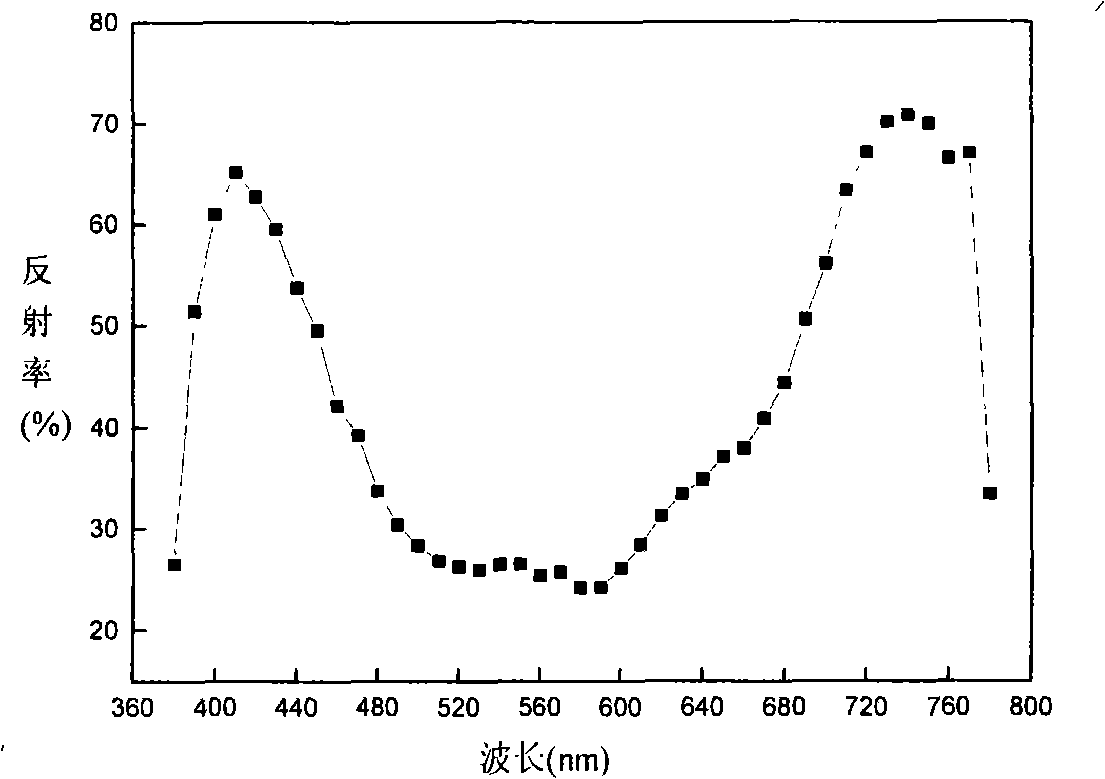

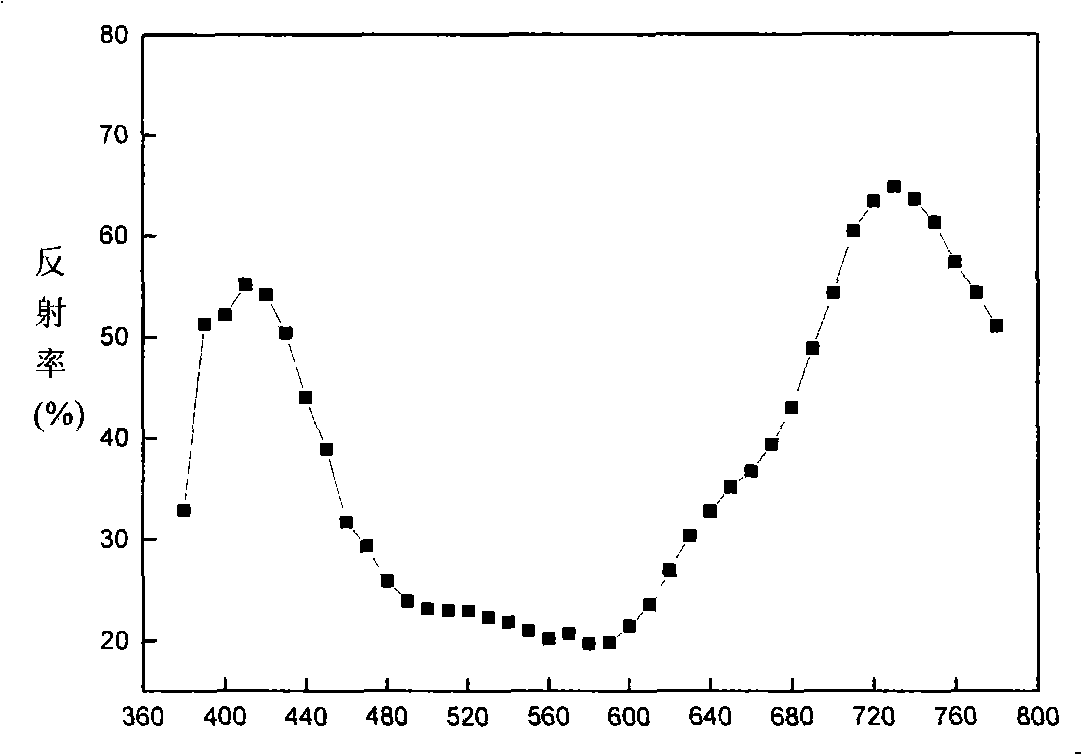

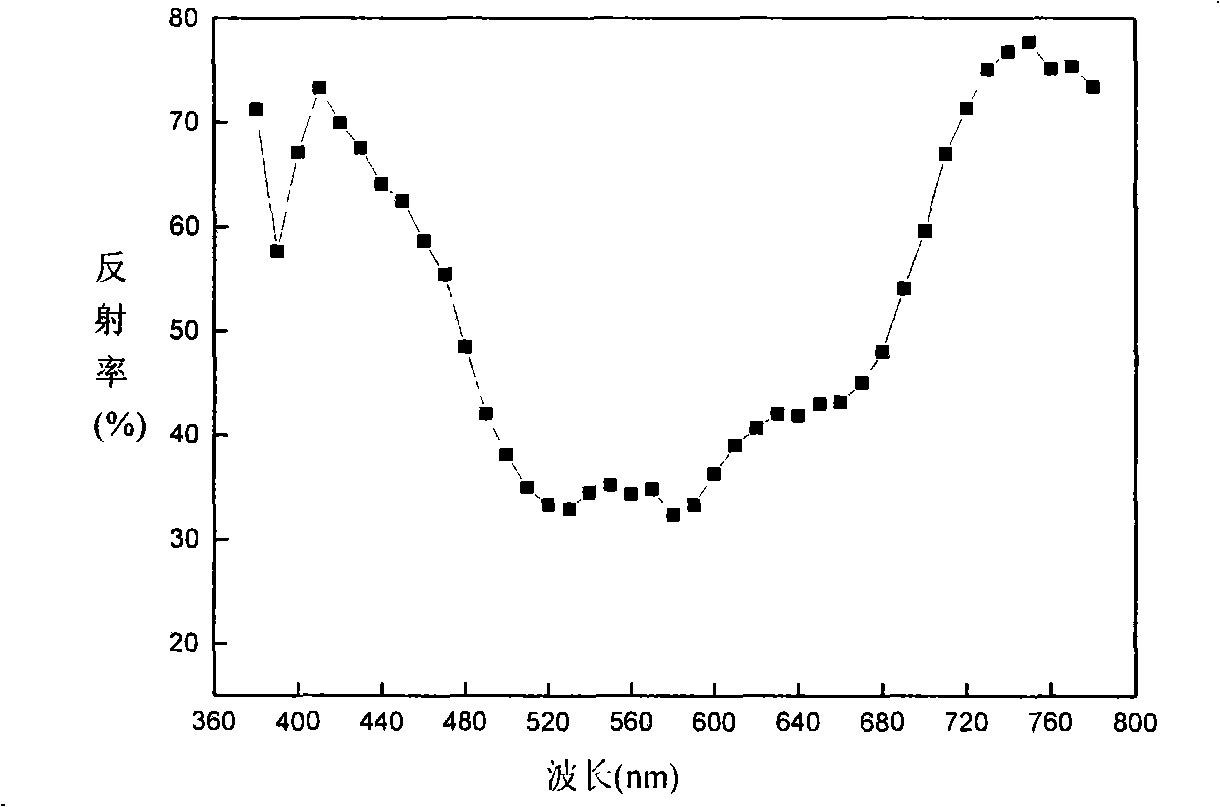

[0018] Using the SP-1000 automatic color measurement spectrophotometer produced by Beijing Kangguang Instrument Co., Ltd., the measured spectral reflectance is shown in the appendix Figure 1-3 , Chromaticity data values are shown in the table below:

[0019] instance number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com