Intelligent monitoring method for cooling wall of blast furnace

A technology of intelligent monitoring and cooling stave, which is applied in the field of blast furnace monitoring and intelligent monitoring of blast furnace cooling stave, which can solve the problems of no intelligent monitoring and safety assessment of blast furnace cooling stave, and achieve rapid and accurate results, simple data collection and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below the present invention is further described, and specific content is as follows:

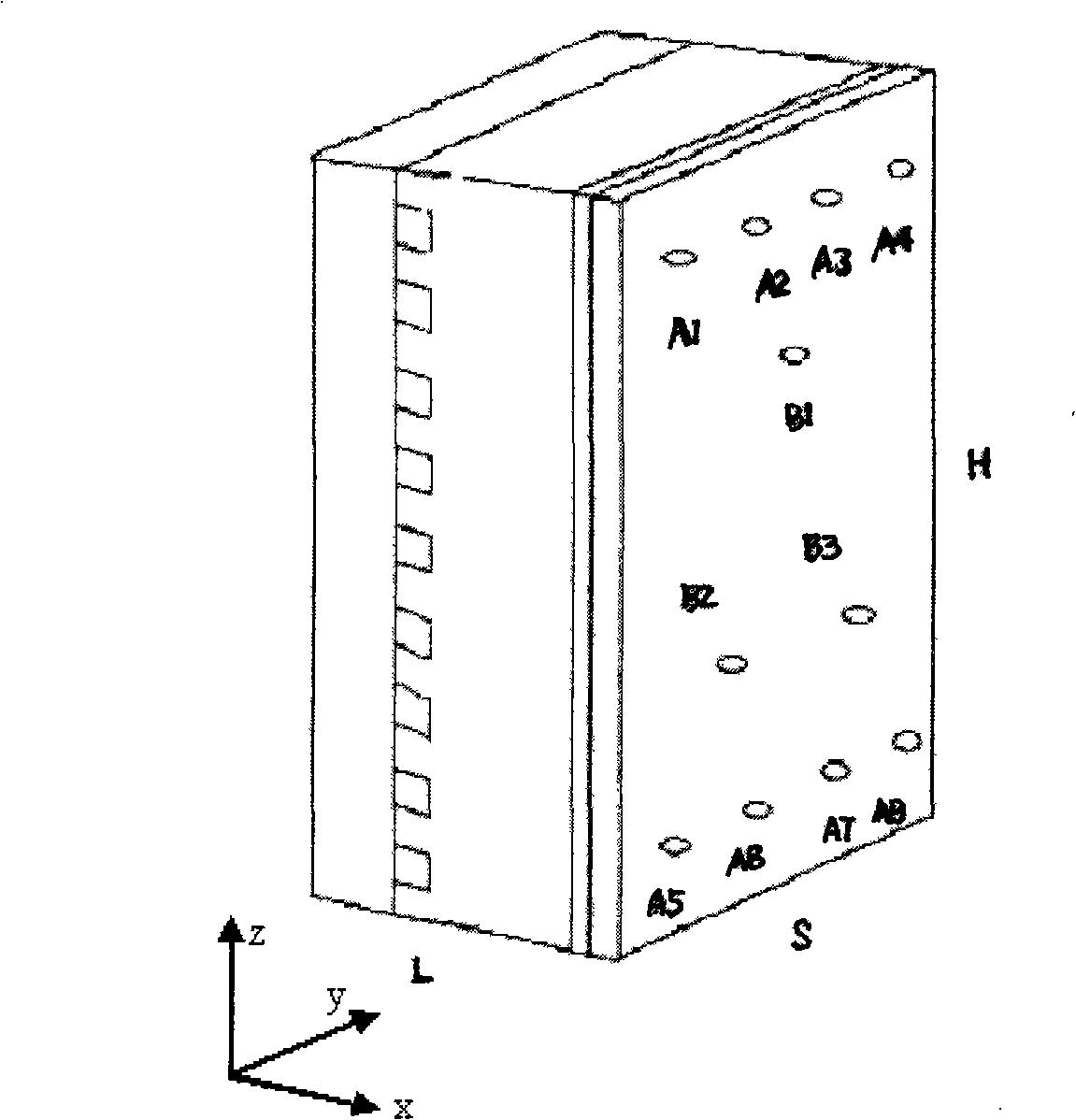

[0038] (1) Position distribution of stave monitoring points, thermocouple packaging and lead-out methods

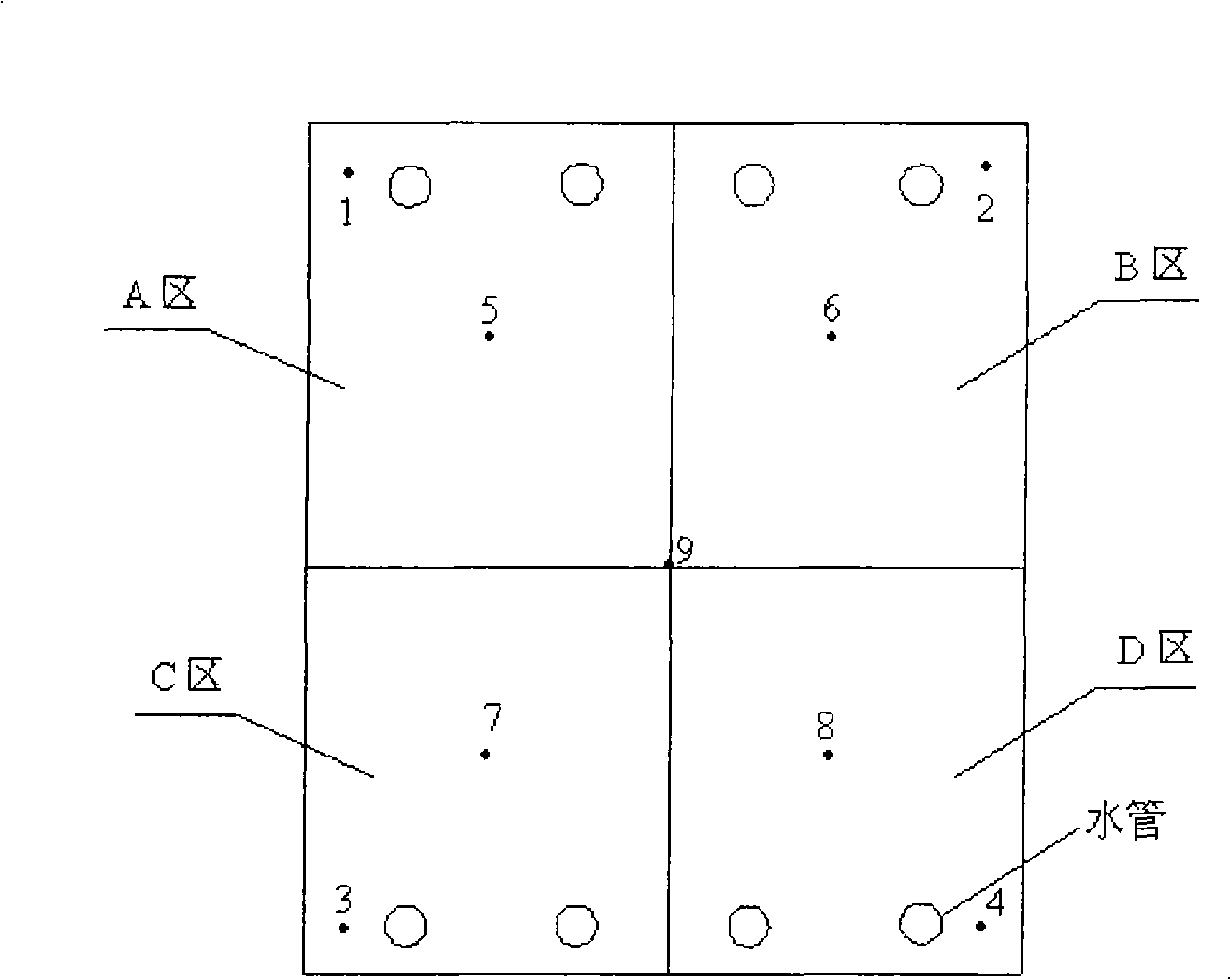

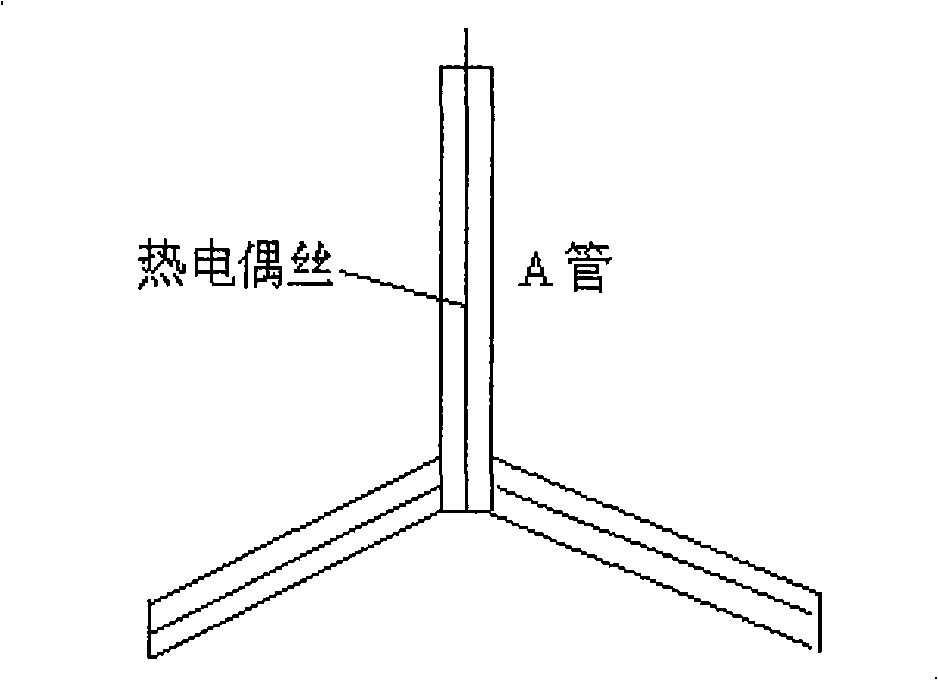

[0039] The position distribution of monitoring points is considered as follows: figure 1 shown. Points 1, 2, 3, and 4 are the corner points of the stave, 50mm away from the cold surface of the stave; points 5, 6, 7, and 8 are the center points of areas A, B, C, and D of the stave, respectively, and are 50mm away from the cold surface of the stave. The cold surface is 50mm, which can basically reflect the local high temperature conditions in the four areas; 9 o'clock is the center point of the whole cooling wall, which is installed at half the thickness of the cooling wall. In order to ensure the accuracy of temperature measurement in the wall, the thermocouple uses a capacitor The impact welding machine welds the hot junction to the bottom of the temperature measuring hole.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com