Endotoxin absorbent and preparation thereof

An adsorbent and endotoxin technology, applied in chemical instruments and methods, suction devices, and other chemical processes, can solve problems such as risk of use, easy generation of particles, and large damage to the strength of agarose gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

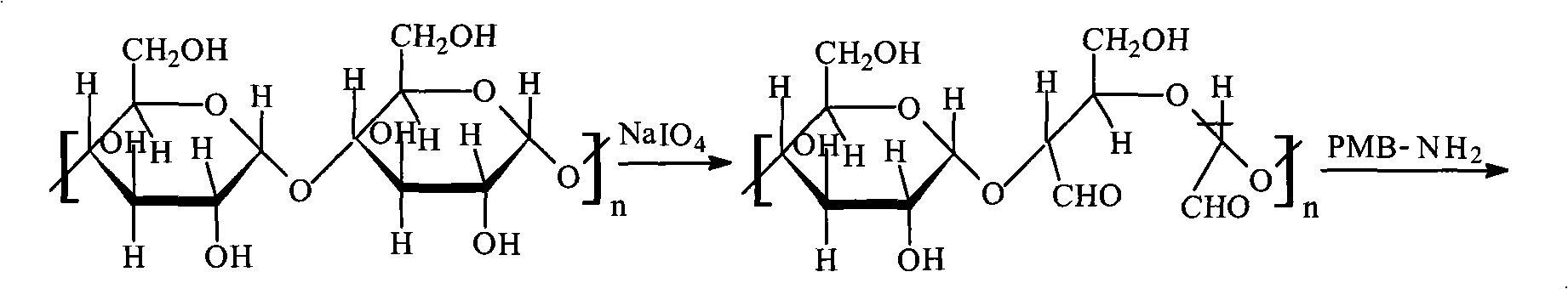

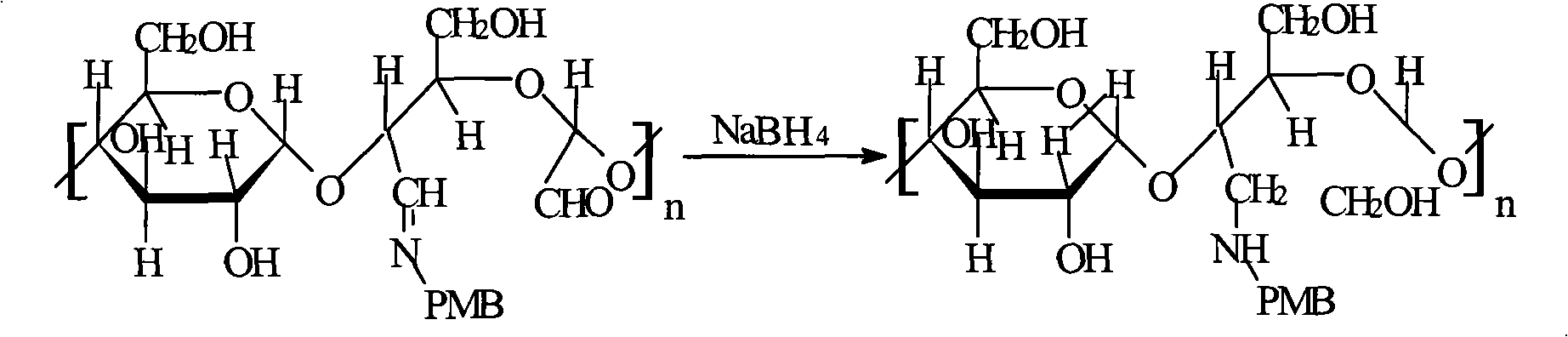

Method used

Image

Examples

Embodiment 1

[0037] A. Sodium periodate activated spherical porous cellulose

[0038] First vacuum filter the spherical porous cellulose to remove surface moisture.

[0039] Add 50 grams of spherical porous cellulose to the three-necked flask, then add 770 ml of purified water, control the temperature at 22 ± 1 ° C, stir to suspend the spherical porous cellulose in the purified water to form a spherical porous cellulose suspension.

[0040] Weigh 1.3 g of sodium periodate in a beaker, add 20 ml of water to dissolve, and make a sodium periodate solution. Add sodium periodate solution into the flask, then add 10ml of water to wash the beaker, pour the washing solution into the flask, continue stirring for 1 hour, raise the temperature to 31±1°C and stir for 10 minutes, filter out the reaction residue, and activate the cellulose The balls were washed twice with purified water and stored at room temperature.

[0041] B. Activated cellulose spheres immobilized polymyxin B

[0042] First weig...

Embodiment 2

[0047] A. Sodium periodate activated spherical porous cellulose

[0048] First vacuum filter the spherical porous cellulose to remove surface moisture.

[0049] Add 50 grams of spherical porous cellulose to the three-necked flask, then add 770 ml of purified water, control the temperature at 26 ± 1 ° C, stir to suspend the spherical porous cellulose in the purified water to form a spherical porous cellulose suspension.

[0050] Weigh 0.8 g of sodium periodate in a beaker, add 20 ml of water to dissolve, and make a sodium periodate solution. Add sodium periodate solution into the flask, then add 10ml of water to wash the beaker, pour the washing solution into the flask, continue to stir for 3 hours, raise the temperature to 34±1°C and stir for 20 minutes, filter out the reaction residue, and activate the cellulose The balls were washed twice with purified water and stored at room temperature.

[0051] B. Activated cellulose spheres immobilized polymyxin B

[0052] First weig...

Embodiment 3

[0057] A. Sodium periodate activated spherical porous cellulose

[0058] First vacuum filter the spherical porous cellulose to remove the surface moisture.

[0059] Add 50 grams of spherical porous cellulose to the three-necked flask, then add 770 ml of purified water, control the temperature at 16 ± 1 ° C, stir to suspend the spherical porous cellulose in the purified water to form a spherical porous cellulose suspension.

[0060] Weigh 1.6 g of sodium periodate in a beaker, add 20 ml of water to dissolve, and make a sodium periodate solution. Add sodium periodate solution into the flask, then add 10ml of water to wash the beaker, pour the washing liquid into the flask, continue to stir for 1 hour, raise the temperature to 31±1°C and stir for 30 minutes, filter out the reaction residue, and activate the cellulose The balls were washed twice with purified water and stored at room temperature.

[0061] B. Activated cellulose spheres immobilized polymyxin B

[0062] First wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com