Iron plate type spanners

An iron plate and wrench technology, applied in the field of wrenches, can solve the problems of high cost plate wrench, low cost, unavailable thickness, etc., and achieve the effects of reducing labor costs, simple components, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Regarding the technology, means and effects adopted in the present invention, a preferred embodiment is given and described in detail below with reference to the drawings.

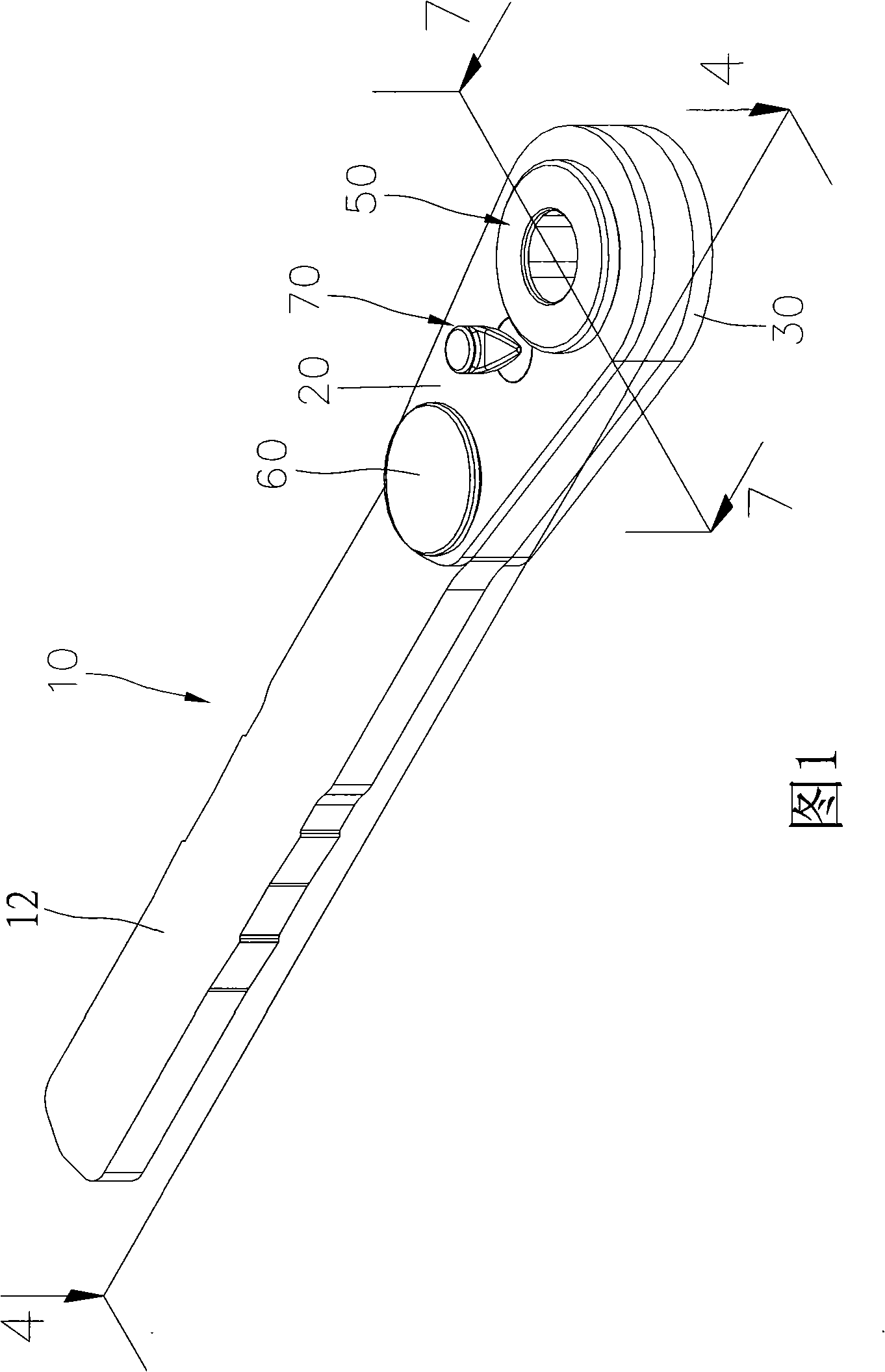

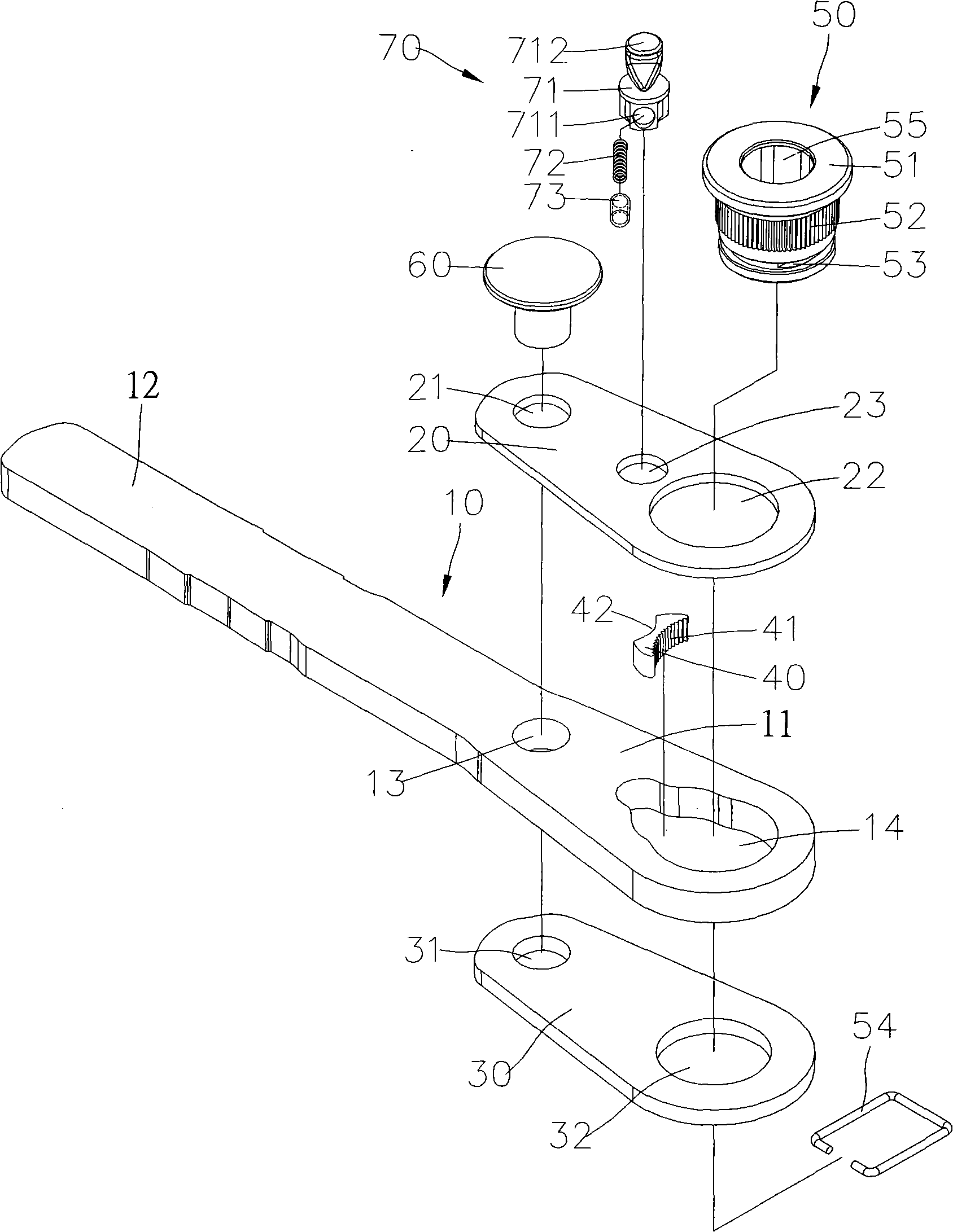

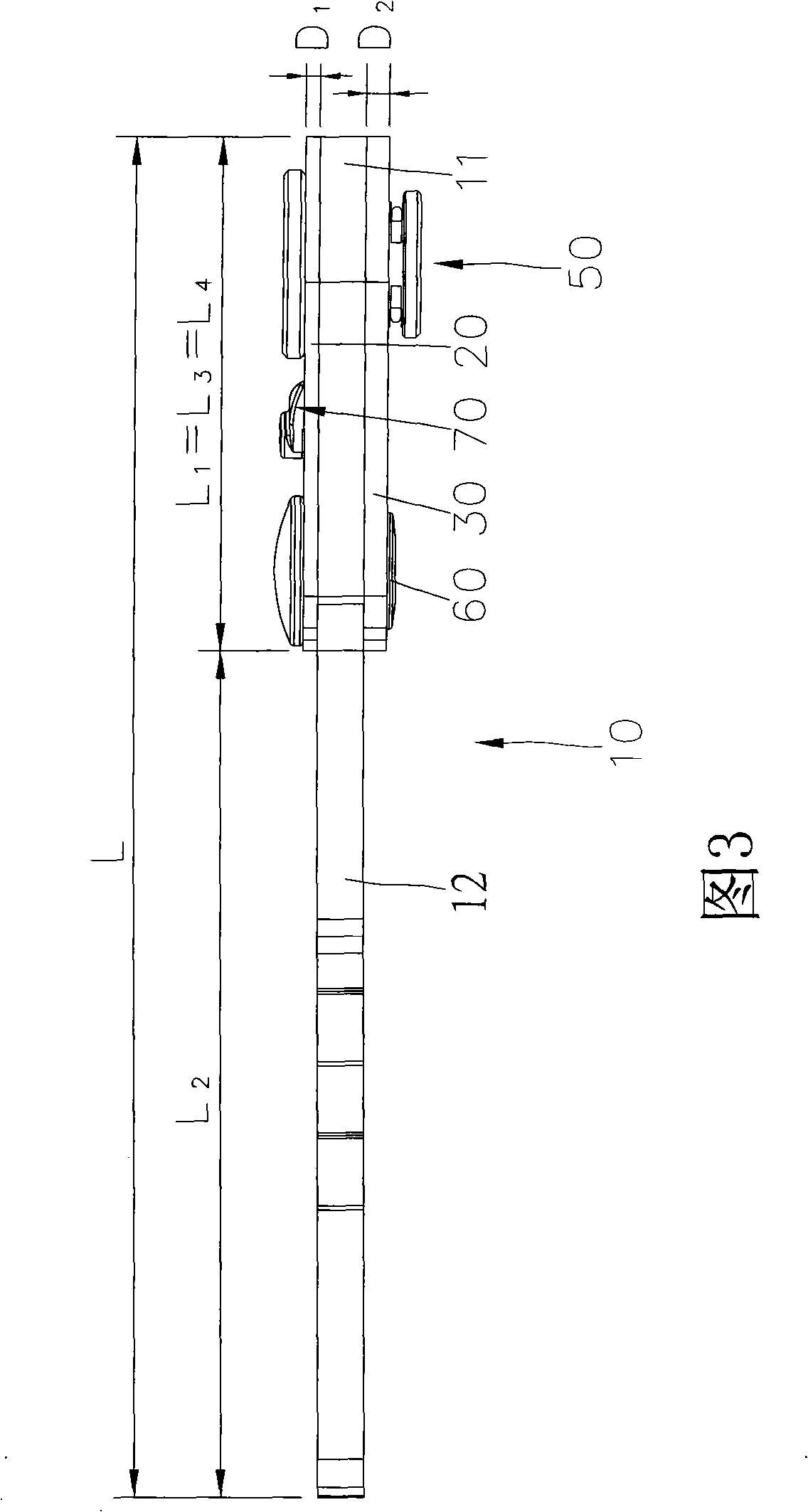

[0032] Referring to Figure 1, figure 2 3 and FIG. 3 are the three-dimensional appearance view, three-dimensional exploded view and front view of the iron plate wrench of the present invention. The iron plate type wrench of the present invention is a two-way drive wrench with reversing function, including a body 10, an upper pressing piece 20 and a lower pressing piece 30, the body 10 and the two pressing pieces 20, 30 are The iron sheet is directly stamped and formed, and the precision mold is used to quickly stamp and form without producing burrs, so that the main body 10 and the two pressing pieces 20, 30 can be stamped into the desired appearance shape, without cumbersome processing, and it is indeed fast in production. advantage. And because the iron plate is easy to obtain, the purpose of rap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com