Non-tower cable crane

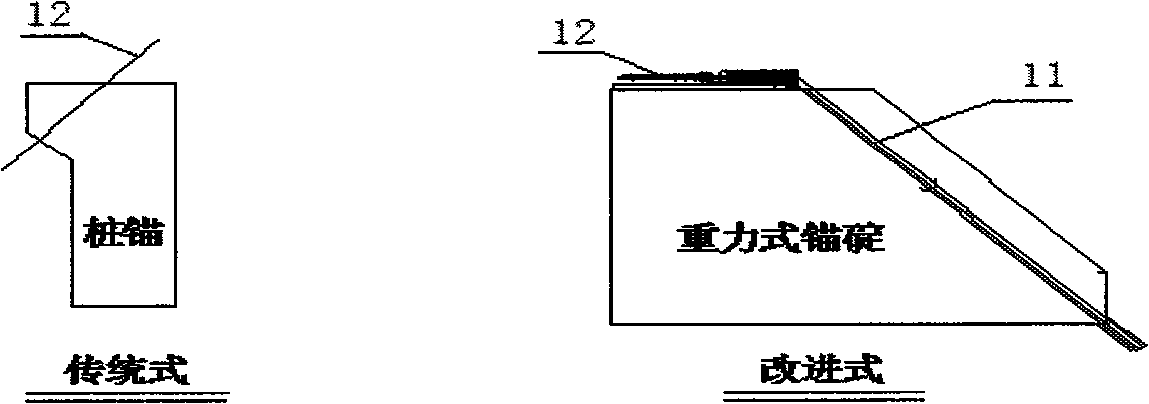

A cable and tower technology, which is applied in the field of cable cranes without towers, can solve the problems of unstable operation of the operating mechanism and hoisting mechanism, reduce the number of winches, etc., and achieve the effects of reducing construction costs, reducing the number of units, and improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiment:

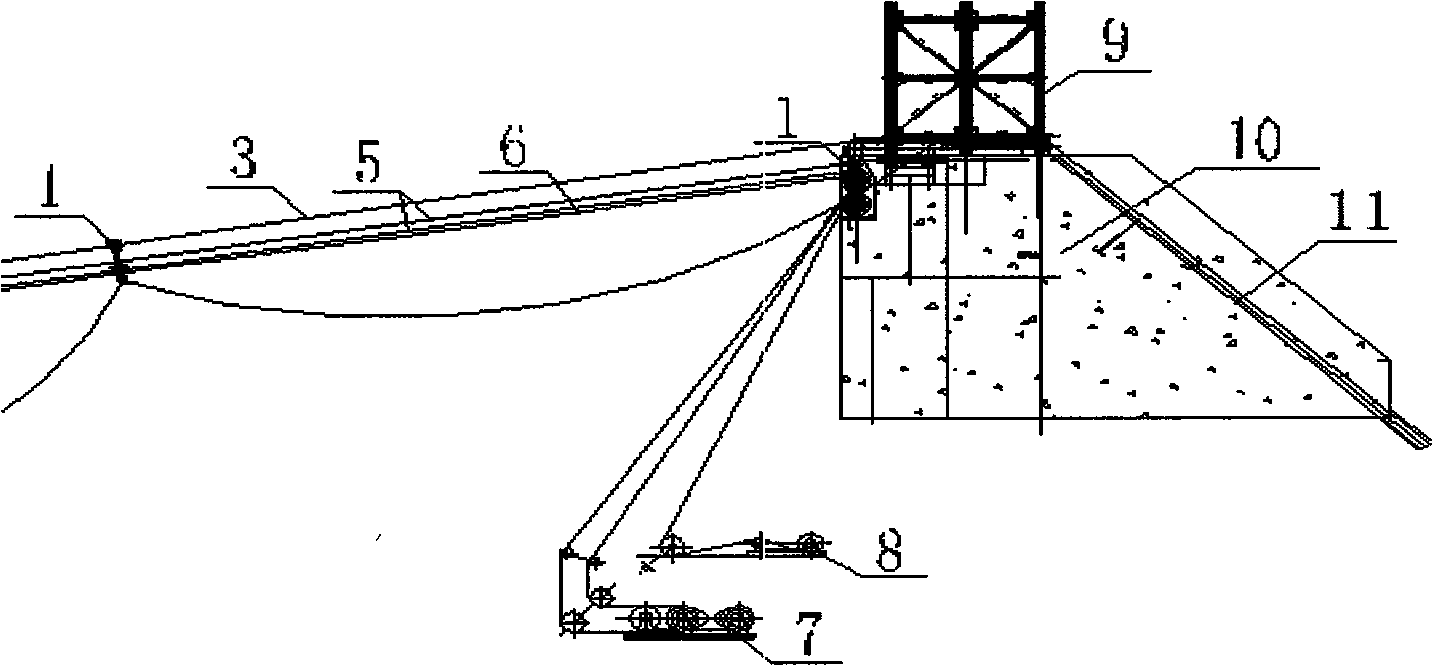

[0029] The towerless cable crane of the present invention is applicable to the cable hoisting device for transporting heavy objects between V-shaped canyons. The design of the "tube spiral friction winch" and "running trolley" solves the problem of unstable operation of the cable hoisting device's operating mechanism and hoisting mechanism.

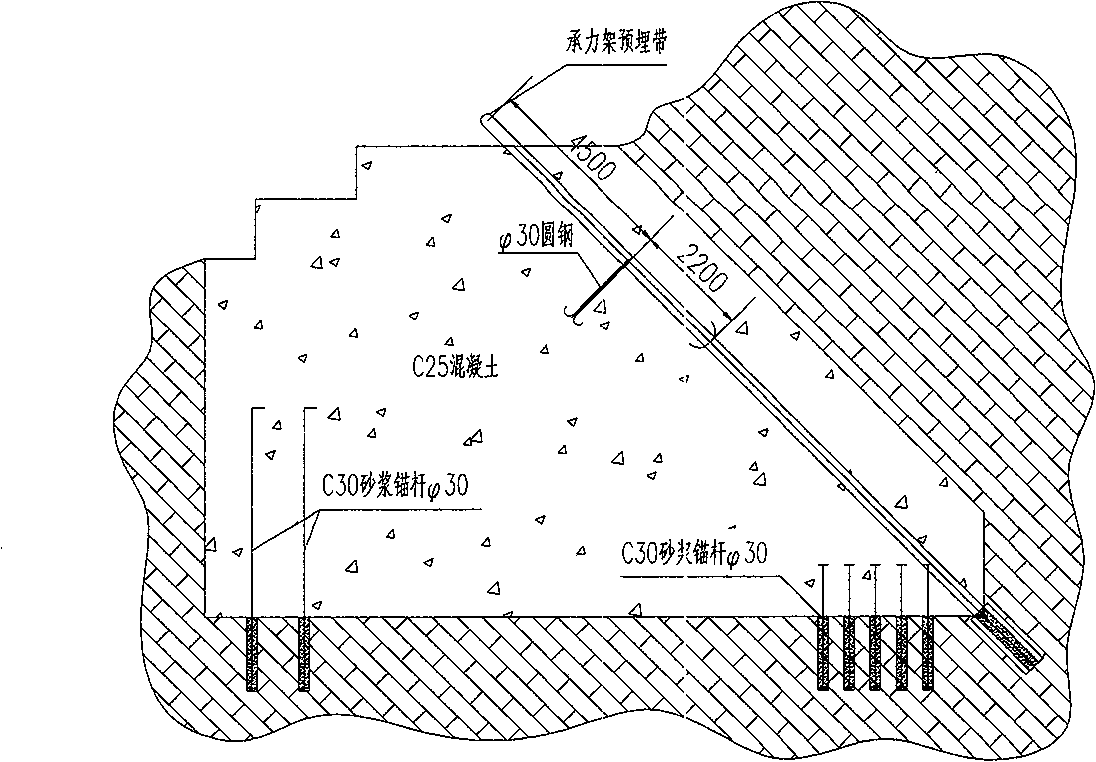

[0030] The hoisting weight is passed to the running trolley through the suspension hook, hoisting rope, and pulley block, and the running trolley is suspended on the load-bearing cable 12 through the running wheels, and finally the load-bearing cable 12 transmits the weight to the cable saddle foundation 10.

[0031] The load-bearing cable deflection system 3 is connected to the cable saddle foundation 10 through the cable saddle 1 and the embedded belt 11 of the middle bearing frame. The ropes 7 and 8 wound on the hoist pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com