Flow guide and ultraviolet disinfecting reactor

A technology of ultraviolet disinfection and deflector, applied in the direction of light water/sewage treatment, irradiation, etc., can solve the problems that the sterilization efficiency needs to be further improved, and achieve the effects of easy implementation and promotion, increased killing quantity, and simple structure

Inactive Publication Date: 2010-12-01

SICHUAN UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this kind of reactor has a simple structure, its bactericidal efficiency needs to be further improved.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

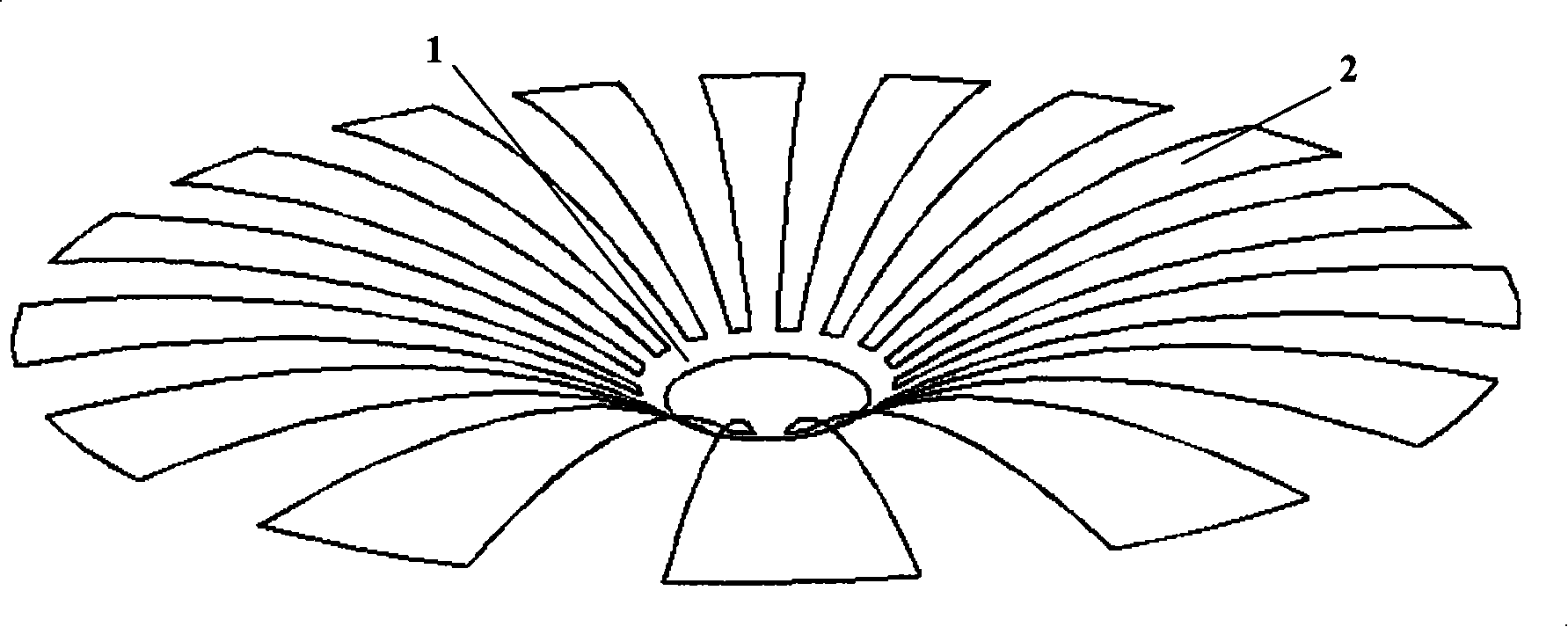

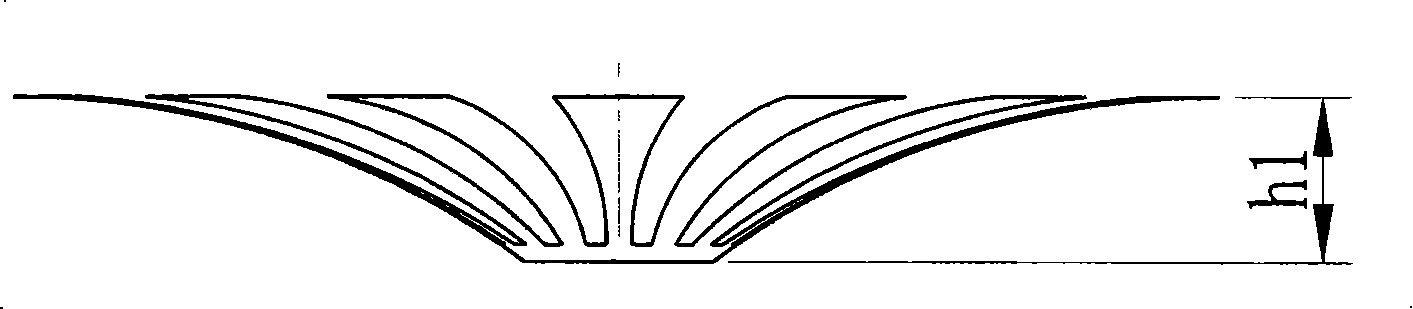

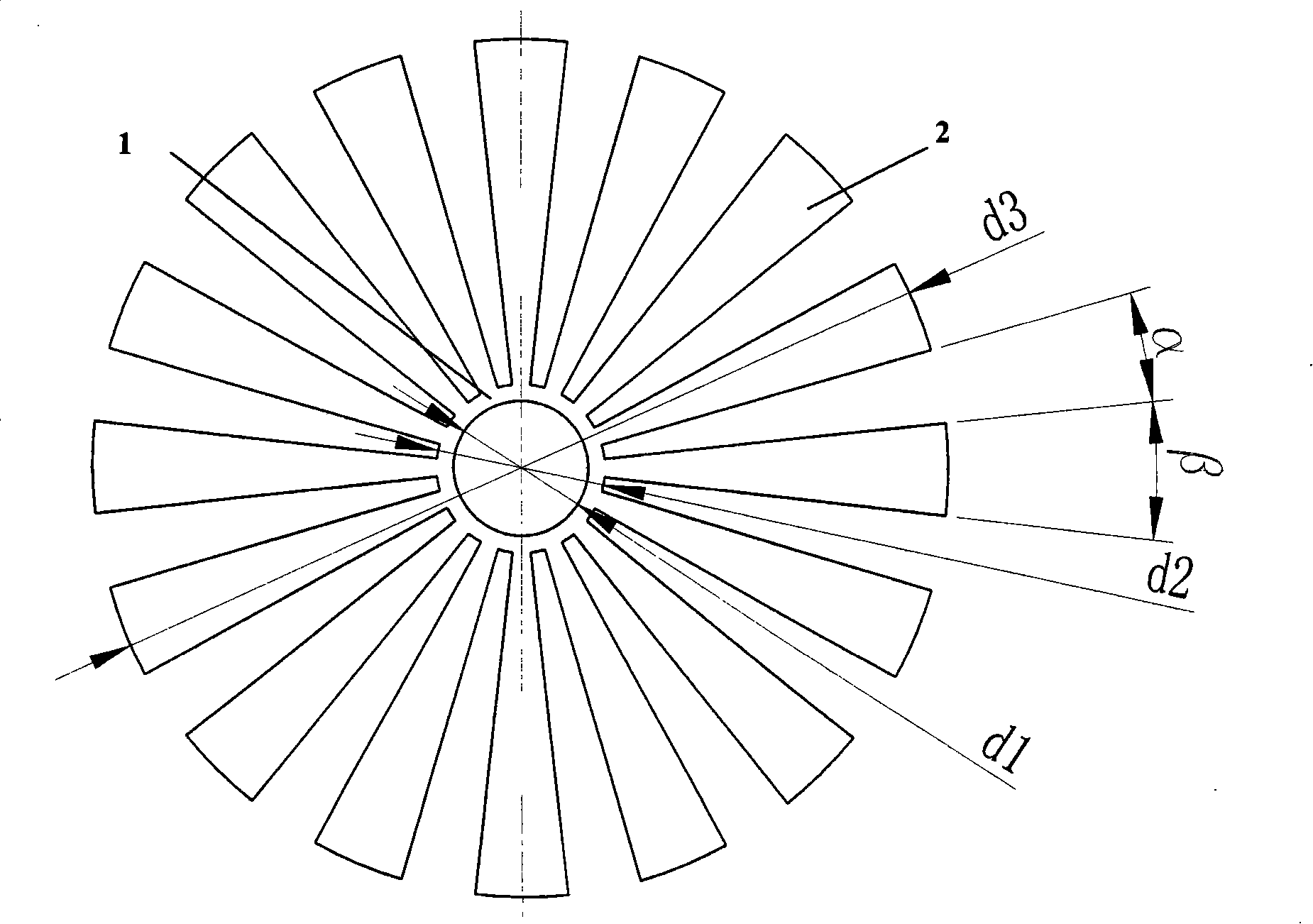

A fluid director comprises an upward-bended arc-ring and at least eight arc discs provided with the radius which is the identical to the axial-bended radius of the arc-ring, and a horizontal projection of each arc disc is a part of the ring, and the central angle is Beta, and the arc discs are equally distributed along the edge of the arc-ring at an interval of the central angle Alpha and are integrated with the arc-ring, wherein, Alpha is less than Beta. An ultraviolet disinfection reactor of the invention comprises a casing, a cover, an ultraviolet light tube, a light tube limiting spring and the fluid director with the above form. A water inlet is cut at the bottom of the casing, and a water outlet is cut on the side wall of the casing; the fluid director is arranged on the lower part of the ultraviolet light tube and on the upper part of the water inlet cut at the bottom of the casing. As the fluid director can change the flowing state of fluid and can increase the flowing time offluid through a certain of path, then the fluid director is arranged in the ultraviolet disinfection reactor to prolong the retaining time of germ in a disinfection cavity so as to enhance the killing rate of germ or to enhance the water quantity to be disinfected with the same germ killing rate.

Description

Flow deflector and UV disinfection reactor technical field The invention relates to a diversion device and an ultraviolet radiation disinfection device for changing the flow state of water flow, in particular to an ultraviolet disinfection reactor and a diverter used in conjunction with it to enhance the killing efficiency of germs. Background technique Ultraviolet disinfection is a method of disinfection of drinking water. When bacteria in drinking water are irradiated by ultraviolet rays, the energy of the ultraviolet spectrum is absorbed by the DNA of the bacteria. When the radiation reaches a certain amount, the DNA structure of the bacteria is damaged, thereby To achieve the purpose of killing germs. It is understood that the existing ultraviolet disinfection reactor for drinking water disinfection includes a shell, a shell cover installed on the upper end of the shell, an ultraviolet lamp installed on the shell cover and located in the shell, and a lamp limiter fixe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A61L2/10C02F1/32

Inventor 周晓泉刘琳莉

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com