Low grade heat energy drive type heat compressor

A thermal compressor, driven technology, applied in the field of compressors in the field of refrigeration technology, can solve problems such as corrosion, and achieve the effects of improving the working state, simplifying the structure, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

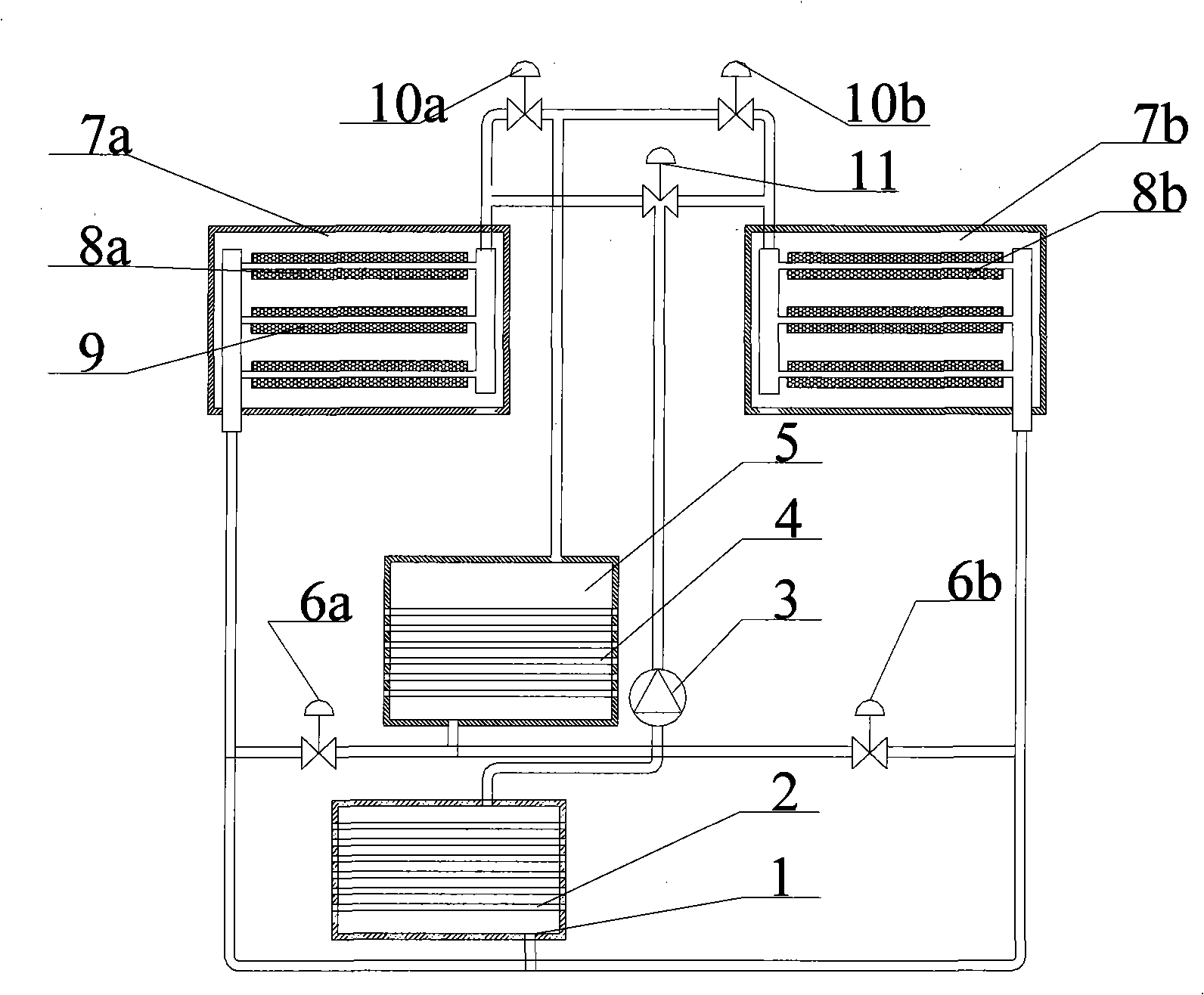

[0010] like figure 1 As shown, the low-grade thermal energy-driven thermal compressor described in this embodiment includes: a cooler 1, a cooling pipeline 2, a water pump 3, a heating pipeline 4, a steam generator 5, a first steam return valve 6a, a second Steam return valve 6b, first adsorption bed 7a, second adsorption bed 7b, first adsorption unit pipe 8a, second adsorption unit pipe 8b, adsorbent 9, first steam heating valve 10a, second steam heating valve 10b, cooling Three-way valve 11. The connection method is: the heating pipeline 4 is located in the steam ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap