Method for preparing garlic product

A product, the technology of garlic juice, which is applied to the preparation of dejuiced garlic, uses acid and alkali to treat garlic and garlic juice, can solve the problems that cannot be widely accepted in modern daily life, etc., and achieves the effects of low cost and simplified production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

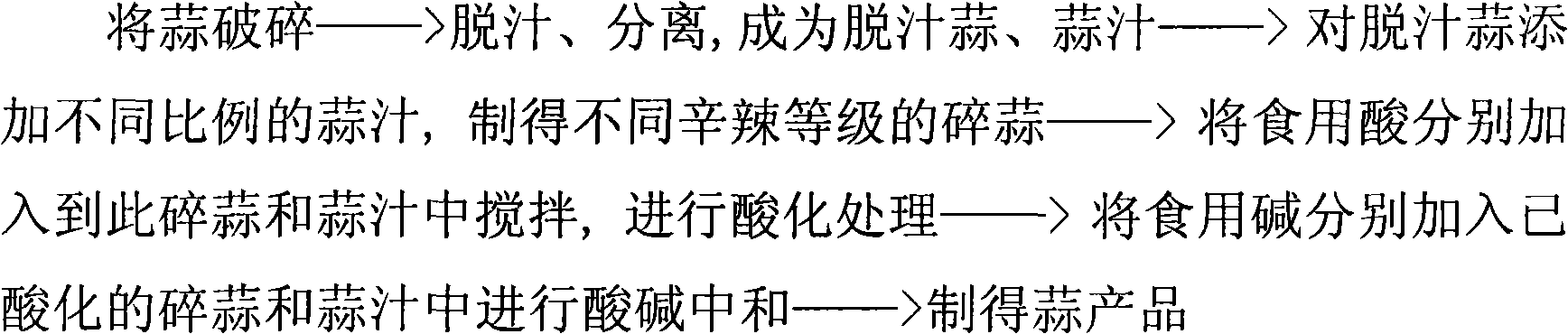

Method used

Image

Examples

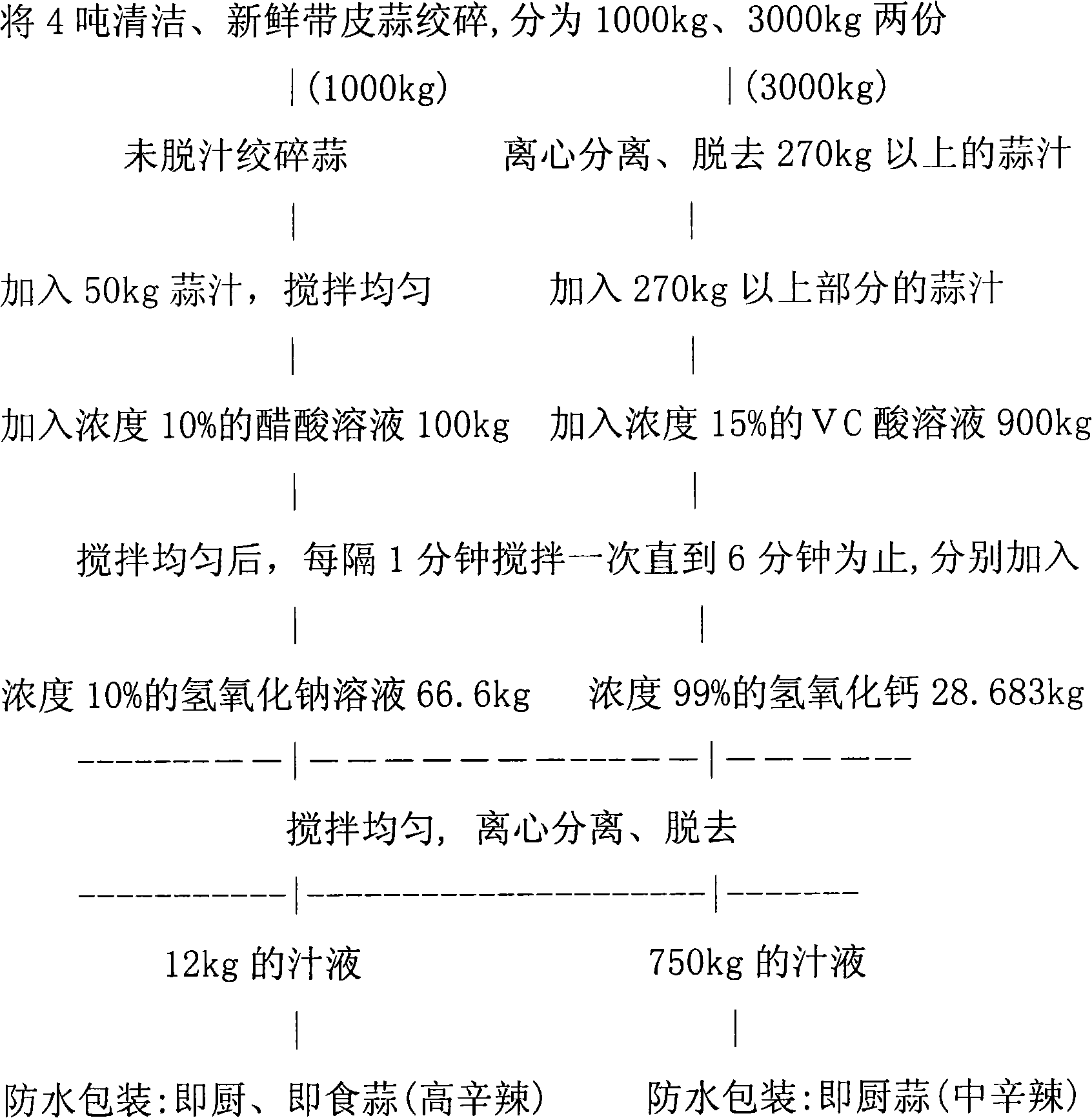

Embodiment 1

[0037] Embodiment 1: The following table illustrates the process of manufacturing raw materials of 1000kg ready-to-eat, 1000kg ready-to-drink, and 1000kg instant kitchen garlic products, and other quantities can be adjusted in corresponding proportions. Do it at a temperature range of 5 to 37 degrees. In addition, when centrifuging and dejuicing 3000kg of minced garlic, it is not fixed at 270kg, but the quantity of more than 270kg that can be easily achieved by the centrifuge used in a single batch. The reason for this is that for most centrifuges, it is more complicated to remove a certain amount (such as 270kg) accurately at a time than to remove any convenient amount above this amount (such as 270kg). Amount and the part above this quantification, promptly with the difference of this quantification (as 270kg), it is very easy to implement, and has reached the purpose of taking off quantification accurately once.

[0038] 1. Crush the raw garlic, remove / add garlic juice, ac...

Embodiment 2

[0043] Embodiment 2, manufacture instant kitchen, instant garlic.

[0044] Crush 3000kg of peeled and cleaned garlic and divide it into two parts of 1000kg and 2000kg. Centrifuge the 2000kg of crushed garlic and remove 100kg (5%) or more of the garlic juice, and add back the garlic that is more than 100kg in weight After making the juice, divide it into two portions of 1000kg each. In the range of 5 to 37 degrees Celsius, the following treatments were carried out respectively.

[0045] Unjuiced crushed garlic (1 ton): Prepare 100kg of naturally brewed vinegar, measure and record the Ph value of the acetic acid, add it to the crushed garlic, and stir evenly. Stir every 1 minute to 3 minutes. Add some concentration of 10% sodium hydroxide solution, the calculation of its addition is referring to the calculation part of the attached examples, (in addition to the calculation of sodium hydroxide consumption, sodium hydroxide can also be added step by step, after stirring, measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com