Metallic separator

A metal separator and metal detection technology, used in instruments, sorting, scientific instruments, etc., can solve the problems of high cost, short service life, affecting the use and maintenance costs of metal separators, and achieve low use and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

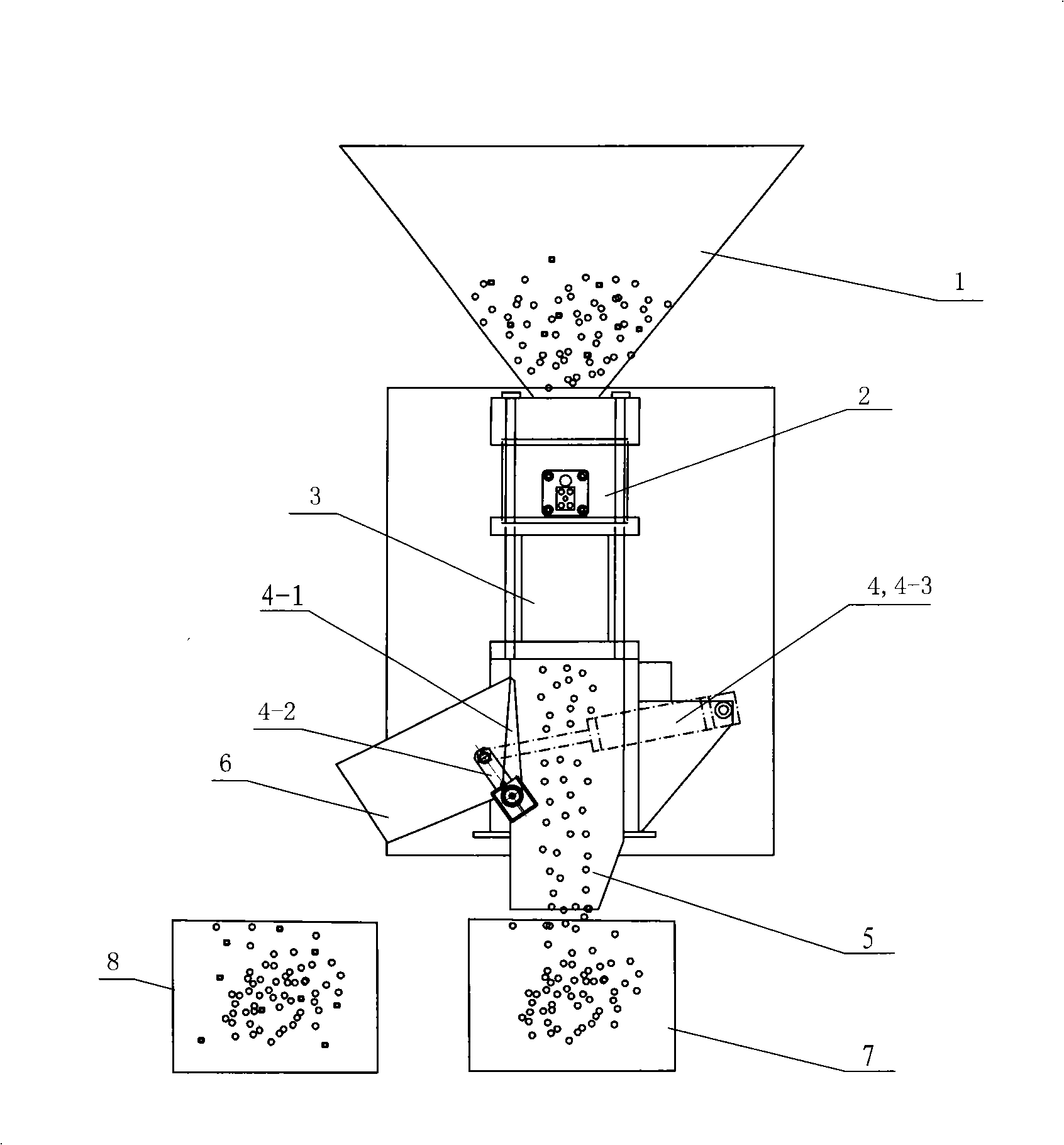

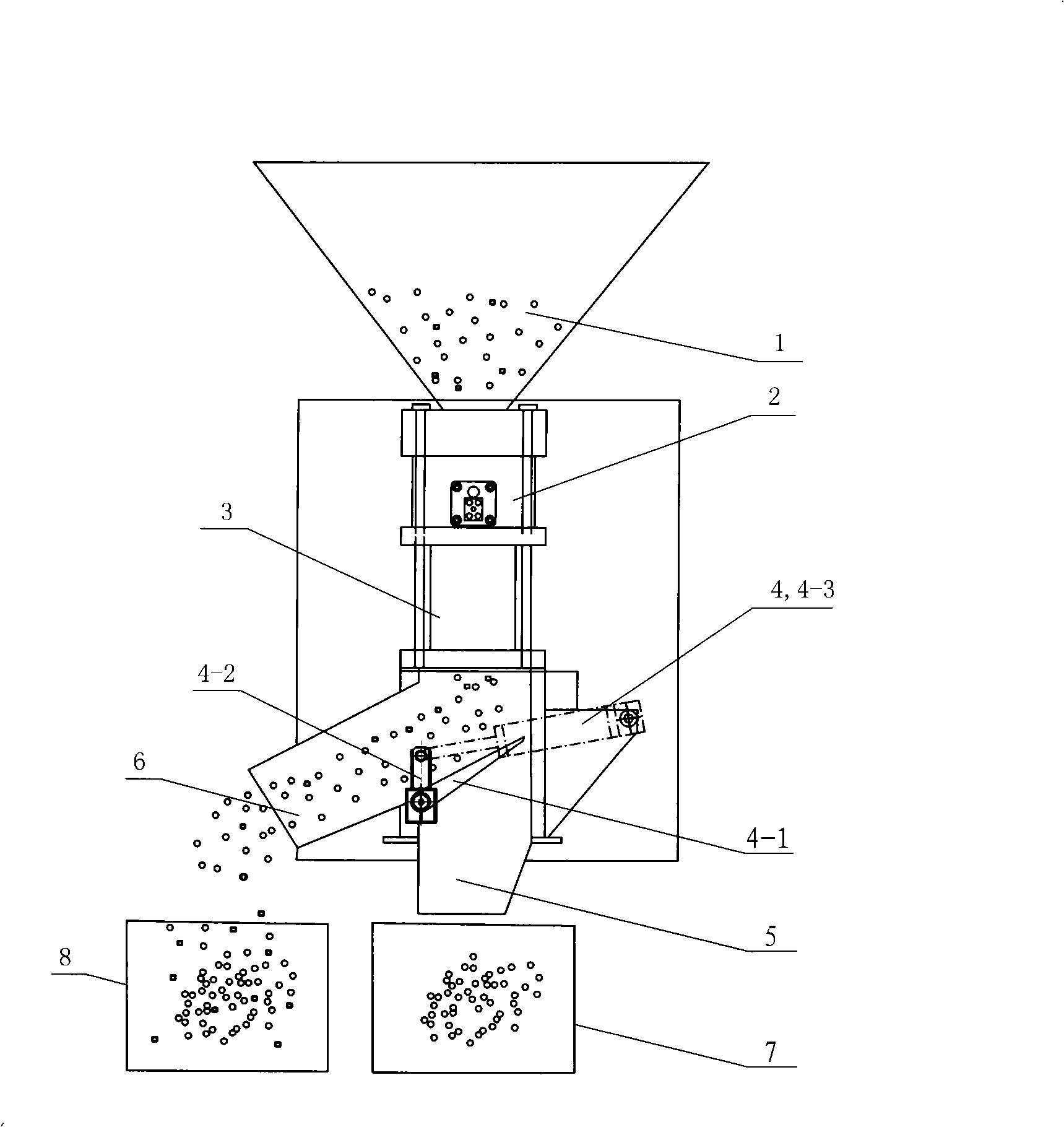

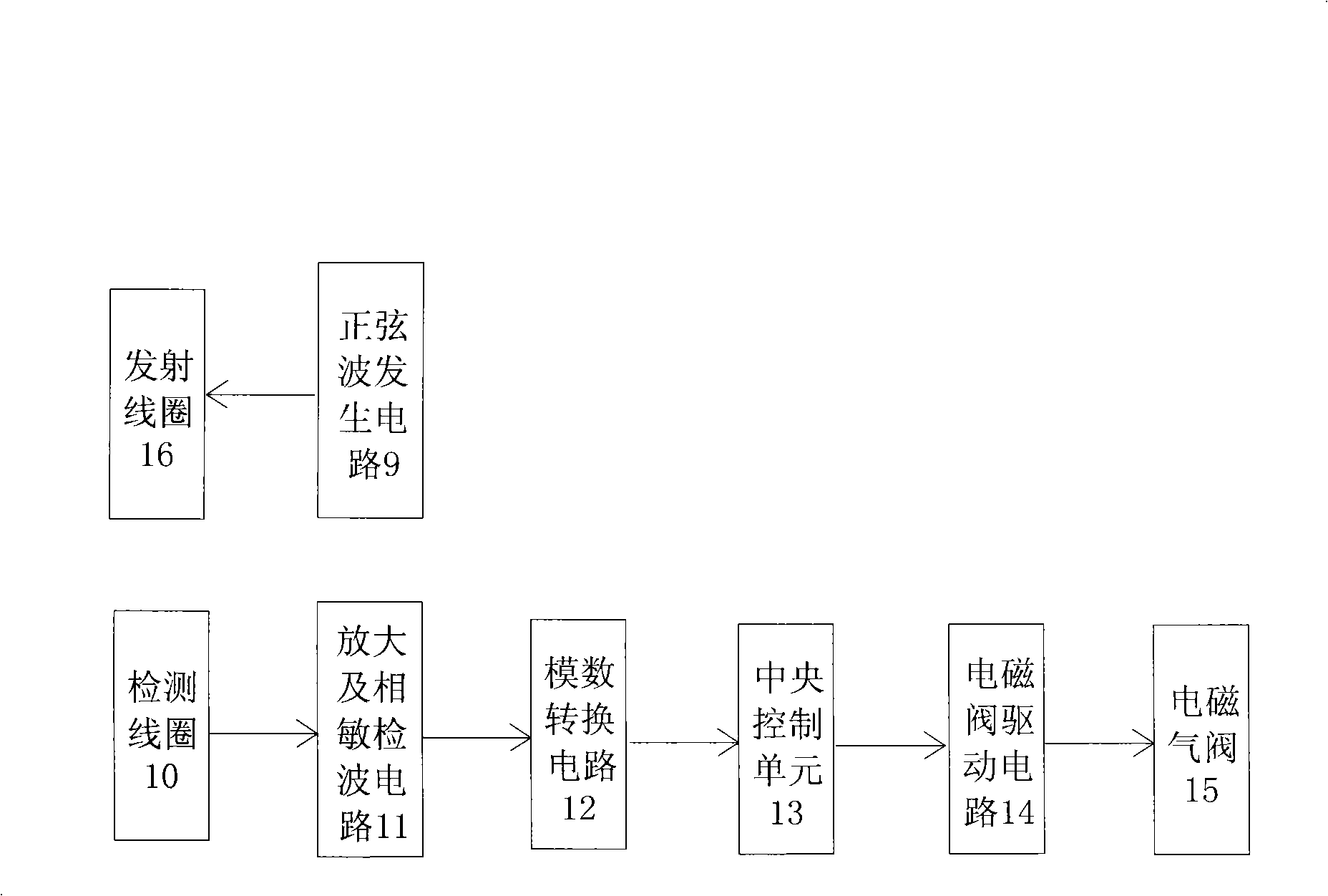

[0023] See Figure 1 to Figure 3 , the metal separator in this embodiment includes: a hopper 1, a metal detection channel 2 located below the hopper 1, a metal detection circuit located on and located on the metal detection channel 2, and a delay channel 3 located below the metal detection channel 2 , a vertically arranged good material channel 5 arranged below the time delay channel 3 , an obliquely arranged metal channel 6 and a separation actuator 4 communicating with the upper end of the good material channel 5 . The metal detection channel 2 is made of polytetrafluoroethylene.

[0024] The separation actuator 4 includes: a baffle plate 4-1 located at the junction of the good material channel 5 and the metal channel 6; the bottom of the baffle plate 4-1 is hinged below the entrance of the metal channel 6, and the baffle plate 4-1 The main part of the main body is located in the good material passage 5; the baffle plate 4-1 can be controlled by the separation actuator 4 or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com