Technique for thinning back side of silicon wafer

A backside thinning and wafer technology, used in manufacturing tools, metal processing equipment, machine tools with surface polishing, etc., can solve the problems of wafer edge bending and fracture, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

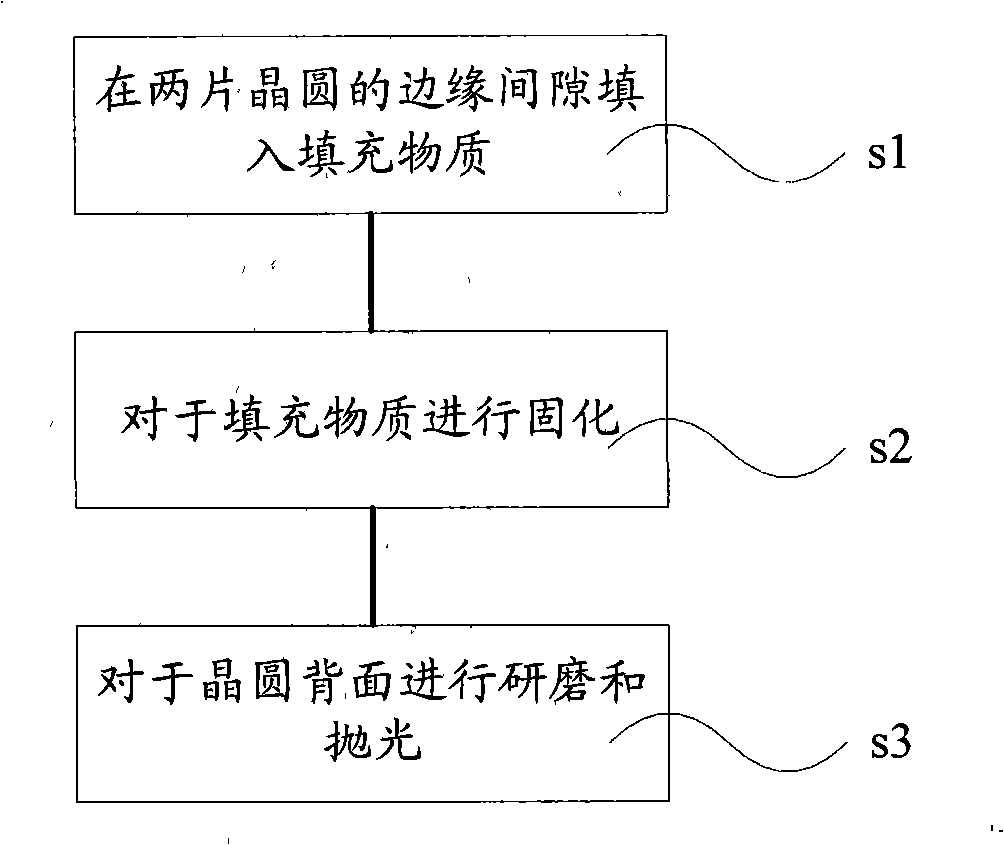

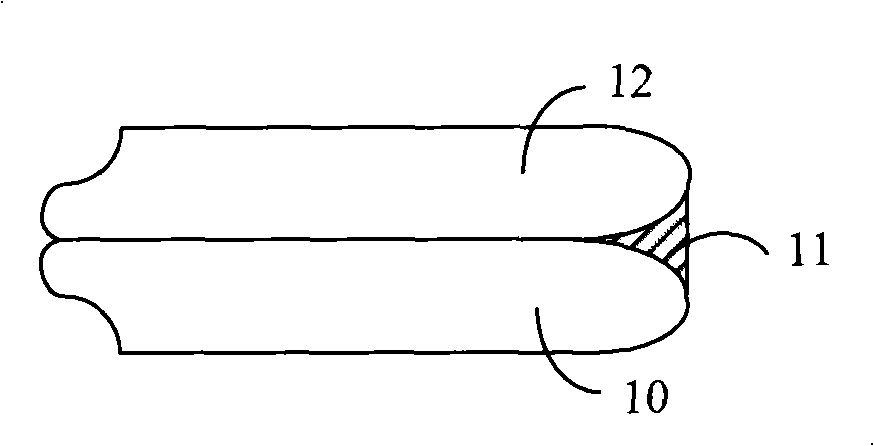

[0020] combine figure 2 and Figure 3A As shown, before wafer 10 and wafer 12 backsides are thinned, the bonded wafer 10 and wafer 12 are first erected by a robotic arm, and then filled with a filling material 11, such as silica gel, by a dispenser. Insert the gap between the circumferential edges of the two wafers, and while filling the silica gel, slowly rotate the two wafers so that the silica gel is evenly filled into the edge gap of the two wafers. Moreover, the thickness of the filled silica gel is 0.5-2mm, such as 0.5mm or 2mm or 1mm. Of course, the filling substance 11 is not limited to silica gel, and can also be other substances that do not react with the grinding slurry.

[0021] combine figure 2 and Figure 3B As shown, after the filling of the filling substance 11 is completed, the filling substance 11 needs to be cured to increase the hardness of the filling substance 11 . A commonly used curing method is to bake the filling substance 11. The curing proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com