Electric locomotive off-shift operation safe monitoring system

A safety monitoring system and technology for electric locomotives, applied in railway signal and safety, railway car body parts, station locking devices, etc., can solve problems that affect the efficiency of locomotive maintenance operations, do not meet the needs, and are prone to accidents, so as to shorten maintenance time The effect of reducing operating time, reducing hidden dangers, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

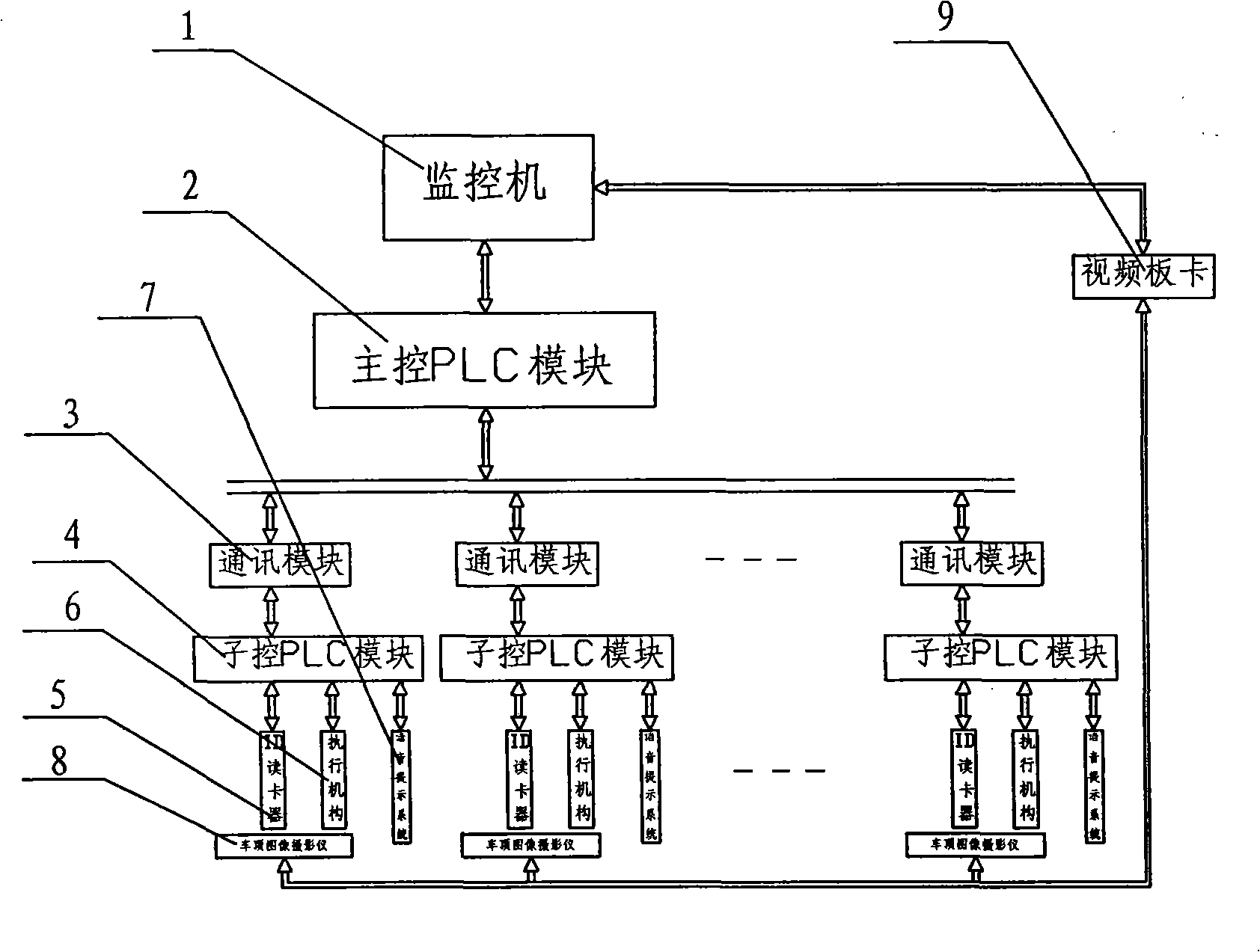

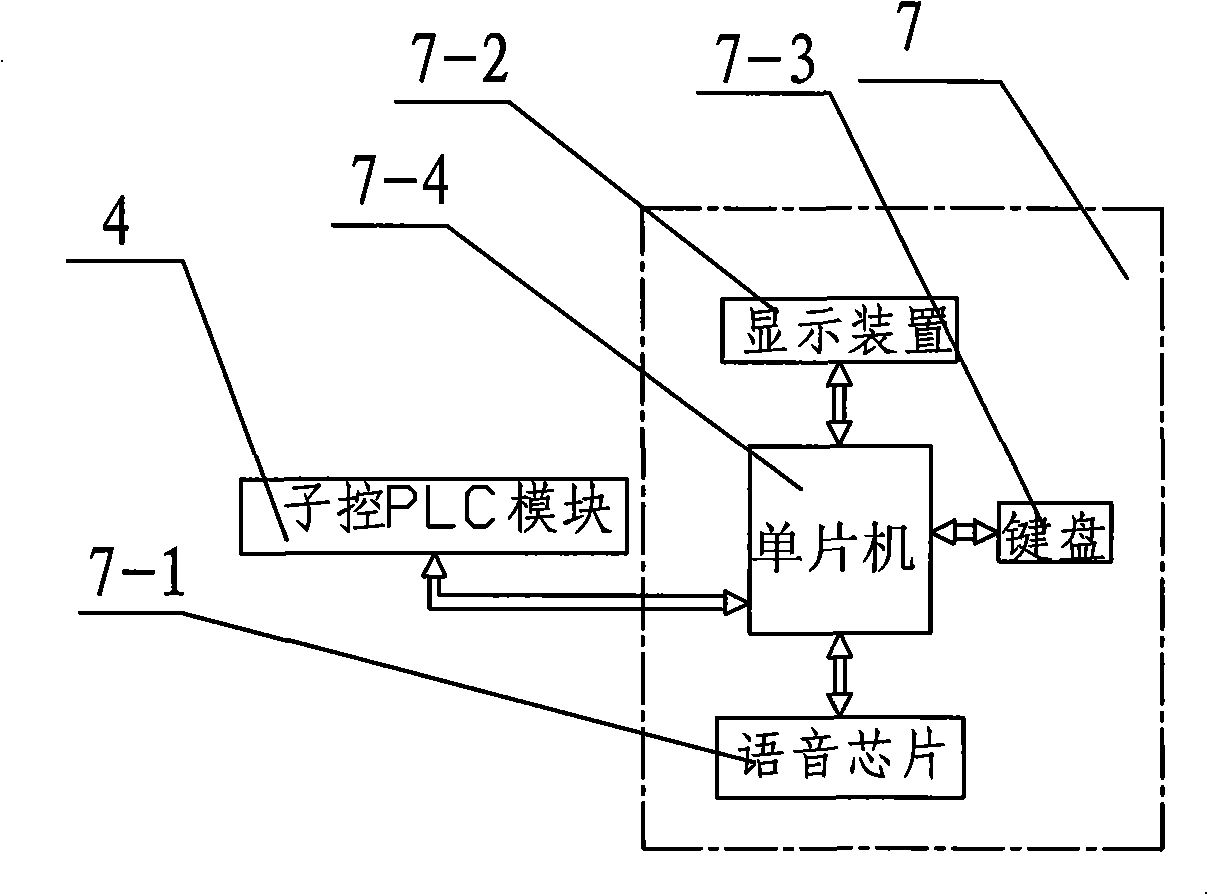

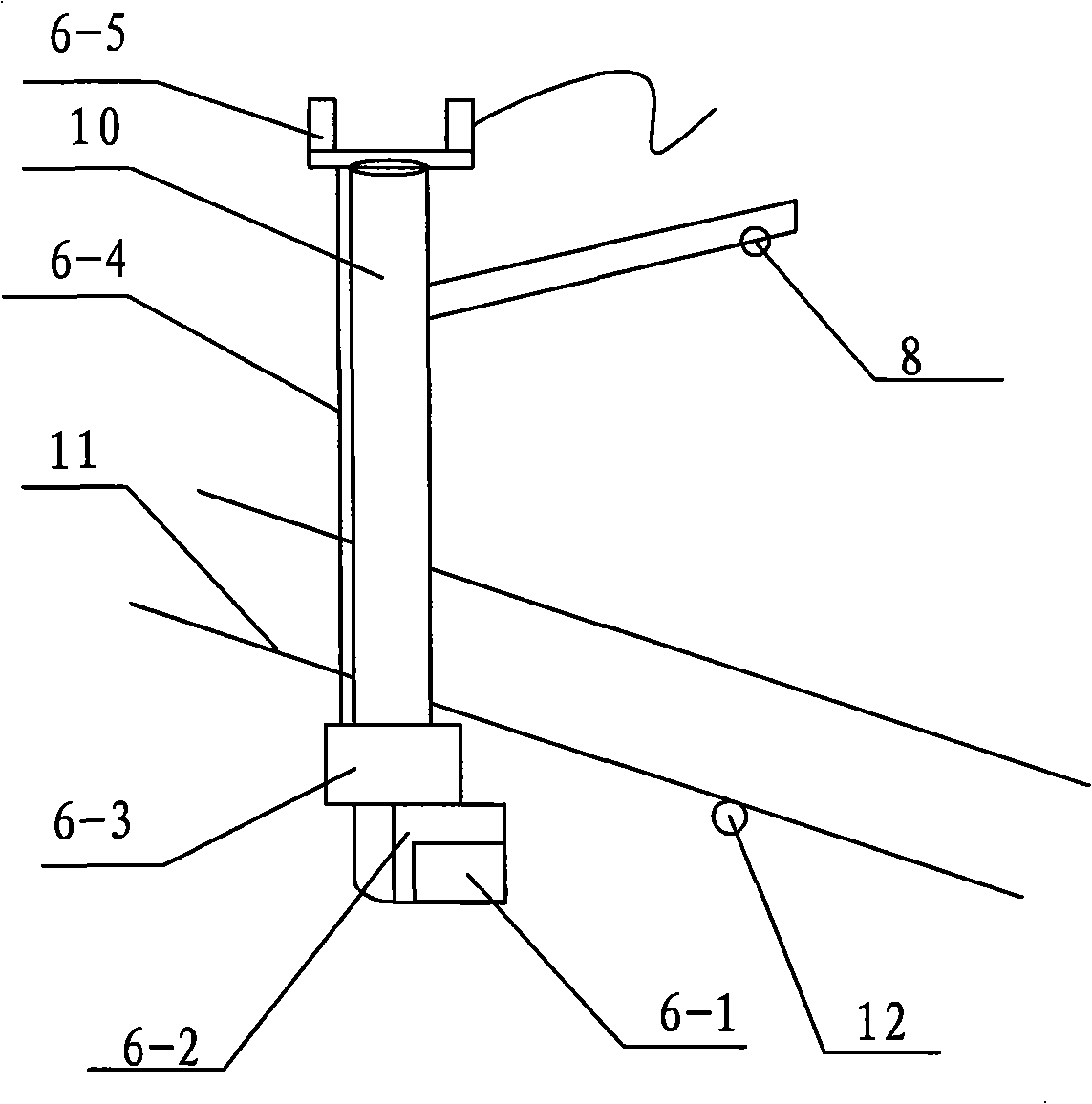

[0064] Example 1, see figure 1 , 2 , 3, 4, the electric locomotive maintenance operation safety monitoring system includes a monitoring machine 1, and the monitoring machine 1 is connected with the master station PLC module 2, and its feature is that it also includes the master station PLC module 2 through the field bus Connected to the communication module 3, the communication module 3 is connected to the PLC module 4 of the slave station, the ID card reader 5, the actuator 6 and the visual input and output system 7 are respectively connected to the PLC module 4 of the slave station, the actuator 6 and the roof image The camera 8 is correspondingly arranged on the column 10 on one side of the track 8 of the electric locomotive maintenance operation, and the roof image camera 8 is connected to the monitoring machine 1 through the video board 9 .

[0065] The monitoring machine 1 is a PC or an industrial computer. The model of the communication module 3 is EM 277. The communi...

Embodiment 2

[0091] Example 2, see Figure 5 , the control method of the electric locomotive maintenance operation safety monitoring system, if offline operation is selected, the operation steps are:

[0092] (1) Voice prompts to swipe the card for operation and maintenance;

[0093] (2), judging whether the receiving of the ID card number is completed, if completed, then enter the next step, if not completed, return to the previous step;

[0094] (3), input the locomotive number, and judge whether the locomotive number is input, if it has been input, then enter the next step, if not input, continue to input the locomotive number and continue to judge;

[0095] (4) The guardian obtains and judges the location of the locomotive, ID card number, extension number and locomotive number, if correct, then enters the next step, if not, returns to the first step;

[0096] (5) The guardian confirms whether the opening condition is satisfied, if it is satisfied, it will enter the next step, if not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com