Slide board for railway passenger dedicated line bridge support, modified ultra-high molecular weight polyethylene and production method for producing the slide board

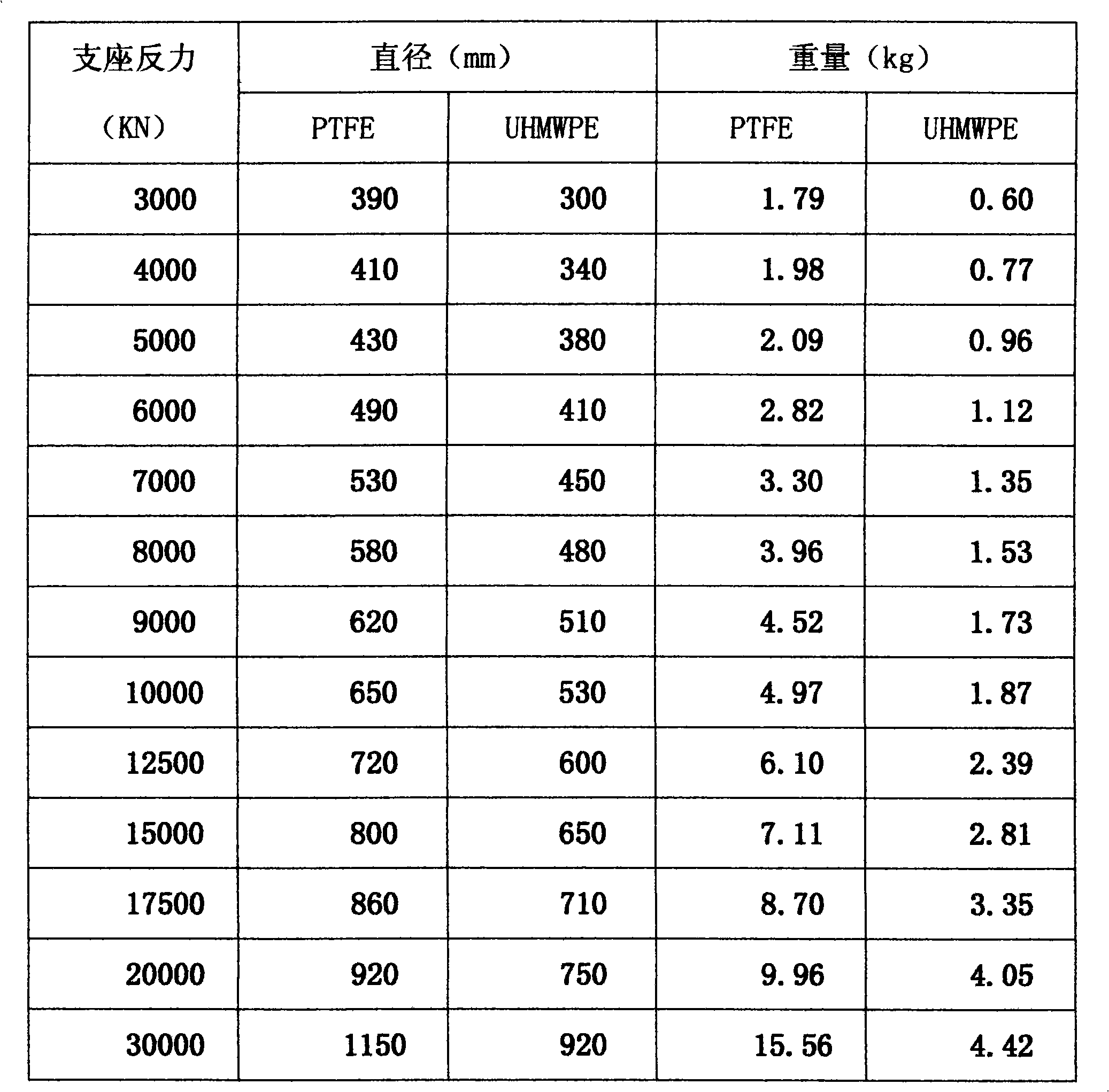

An ultra-high molecular weight, passenger-dedicated line technology, applied in the field of slide plates for bridge supports, can solve the problems of wasting materials, increasing the construction cost of railway passenger-dedicated lines, and the weight of PTFE plates, so as to reduce the weight of supports and prevent relative sliding , Improve the effect of stamping resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step is to prepare a masterbatch according to the weight percentage of ultra-high molecular weight polyethylene 85%, low molecular weight polytetrafluoroethylene 2%, polybismaleimide 6%, molybdenum disulfide 4%, silicone oil 3%, and stir Evenly, take the composition according to the weight of the bridge bearing of the required railway passenger dedicated line, and pack it into a mould;

[0033] Step 2: Heat the mold to a temperature of 270°C-285°C, a pressure of 24Mpa, and a duration of 30 minutes;

[0034] Step 3: Cool the mold and take out the slide;

[0035] Step 4: Dimple the upper surface of the skateboard by mechanical means, and grind the lower surface of the skateboard to a rough surface.

Embodiment 2

[0037] The first step is to prepare a masterbatch according to the weight percentage of ultra-high molecular weight polyethylene 93%, low molecular weight polytetrafluoroethylene 1%, polyamide fiber 2%, molybdenum disulfide 2%, ethylene-propylene copolymer 2%, and stir Evenly, take the composition according to the weight of the bridge bearing of the required railway passenger dedicated line, and pack it into a mould;

[0038] Step 2: Heat the mold to a temperature of 260°C to 270°C, a pressure of 26Mpa, and a duration of 40 minutes;

[0039] The third step and the fourth step are the same as in Example 1.

Embodiment 3

[0041] The first step is to prepare a masterbatch according to the weight percentage of 89% of ultra-high molecular weight polyethylene, 2% of low molecular weight polytetrafluoroethylene, 3% of polyamide fiber, 3% of molybdenum disulfide, and 3% of rare earth, and stir evenly. The composition needs to be weighed according to the weight of the bridge bearing of the railway passenger dedicated line, and packed into a mould;

[0042] Step 2: Heat the mold to a temperature of 260°C to 270°C, a pressure of 26Mpa, and a duration of 50 minutes;

[0043] The third step and the fourth step are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com