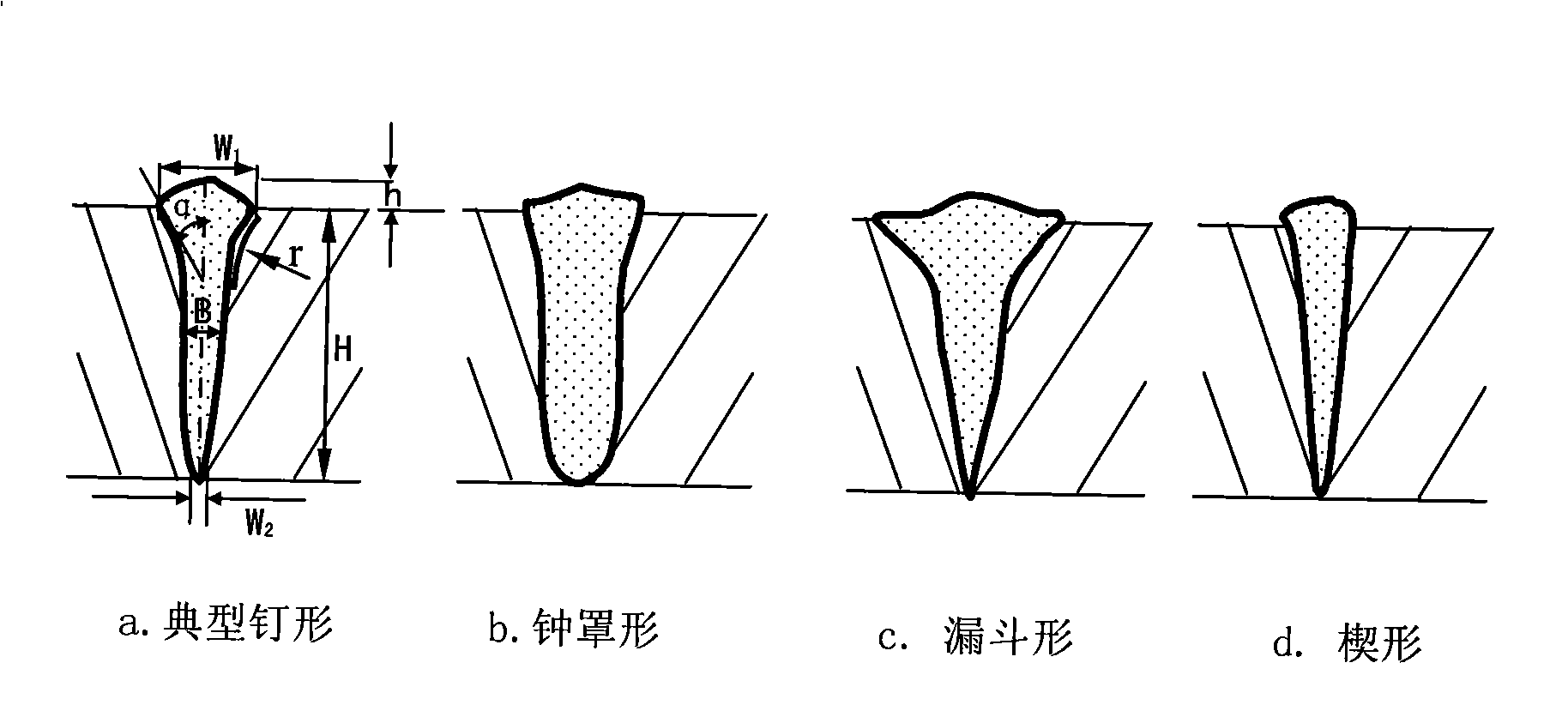

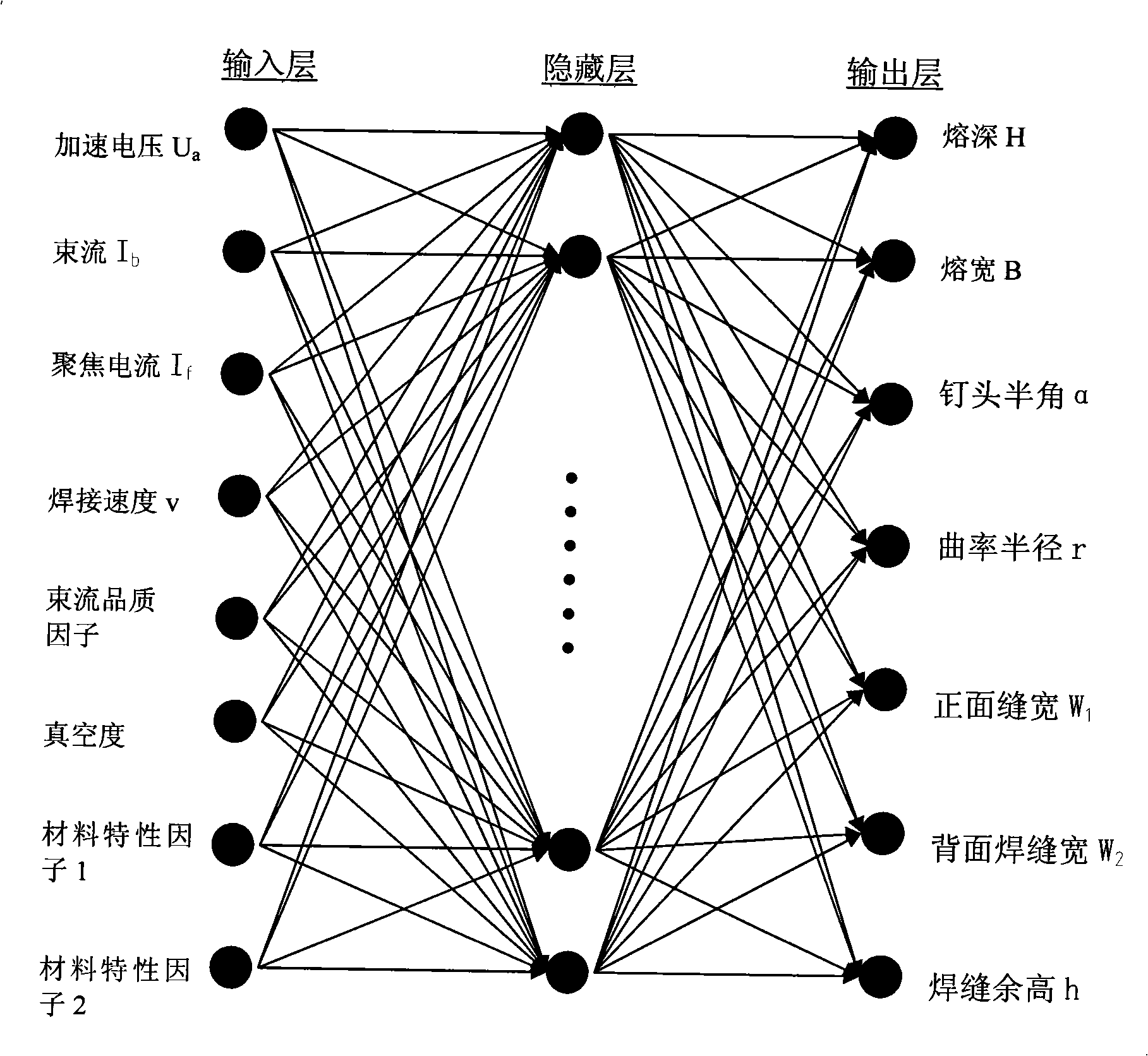

Neural network modeling approach of electron-beam welding consolidation zone shape factor

A technology of neural network modeling and electron beam welding, which is applied in the field of neural network modeling, can solve the problems of few input layer parameters and insufficient comprehensiveness, and achieve the effect of concise model, saving materials and improving the progress of engineering research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

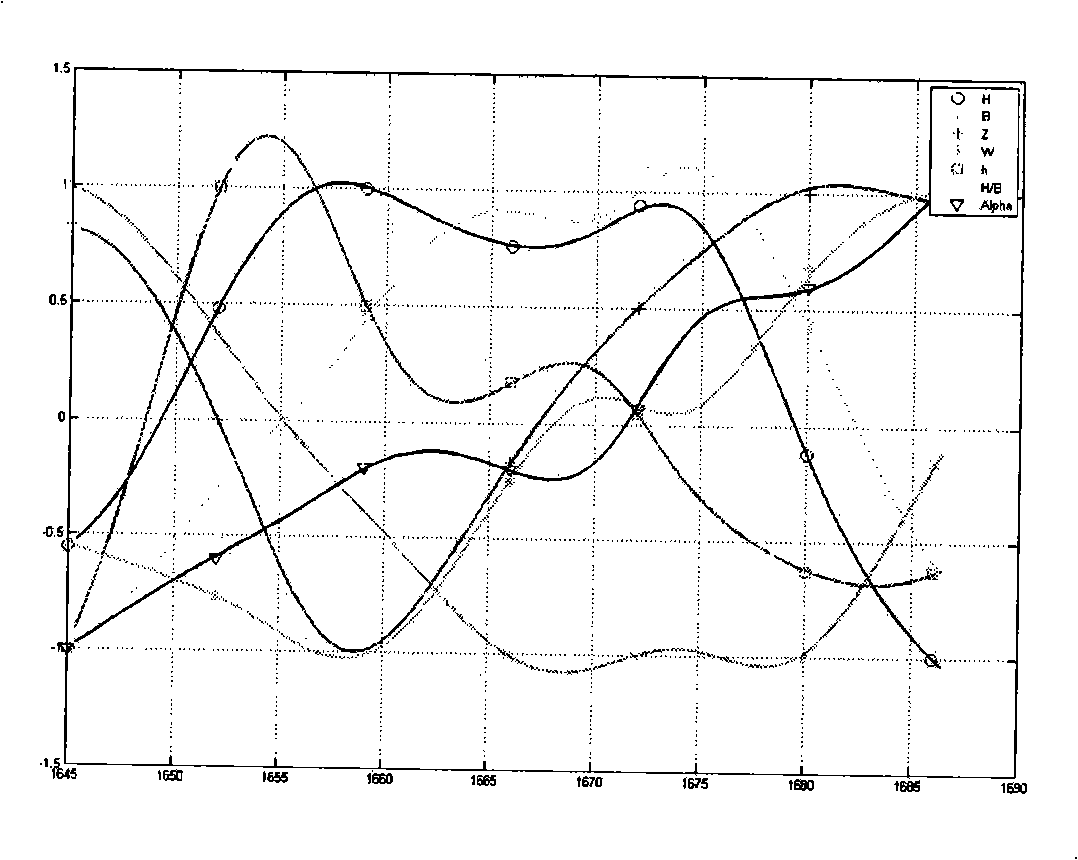

Examples

Embodiment 1

[0069] 1. Electron beam welded joint sample preparation

[0070] Electron beam welding δ = 20mm TC4 titanium alloy test plate process, adopts flat plate surfacing welding method to simulate the best butt joint form, and the size of welding material TC4 titanium alloy is 300mm×90mm×20mm. Welding is performed in an electron beam welder after removing the oxide film with a wire brush.

[0071] The welding parameters are as follows:

[0072] u a - Accelerating voltage, I b - Beam I f -focus current V-welding speed, H-distance from the gun to the test piece

[0073] Parameter 1: U a =150kV, I b = 42mA, I f =342mA, V=600mm / min, H=251mm, vacuum 6×10 -3 Pa

[0074] Parameter 2: U a =150kV, I b =69mA, I f =366mA, V=600mm / min, H=251mm, vacuum 4×10 -3 Pa

[0075] Parameter 3: U a =150kV, I b = 42mA, I f =324mA, V=400mm / min, H=251mm, vacuum 4×10 -3 Pa

[0076] Parameter 4: U a =90kV, I b =57mA, I f =1654mA, V=750mm / min, H=370mm, vacuum 3.2×10 -4 Pa

[0077] Paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com