Insulation structure of friction specimen holder and apparatus body in current-carrying frictional wear experiment

A sample fixture and wear test technology, which is applied in the testing of machine/structural components, testing of wear resistance, testing of mechanical components, etc., can solve problems such as distortion of test results, loss of test current, and influence on rotation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

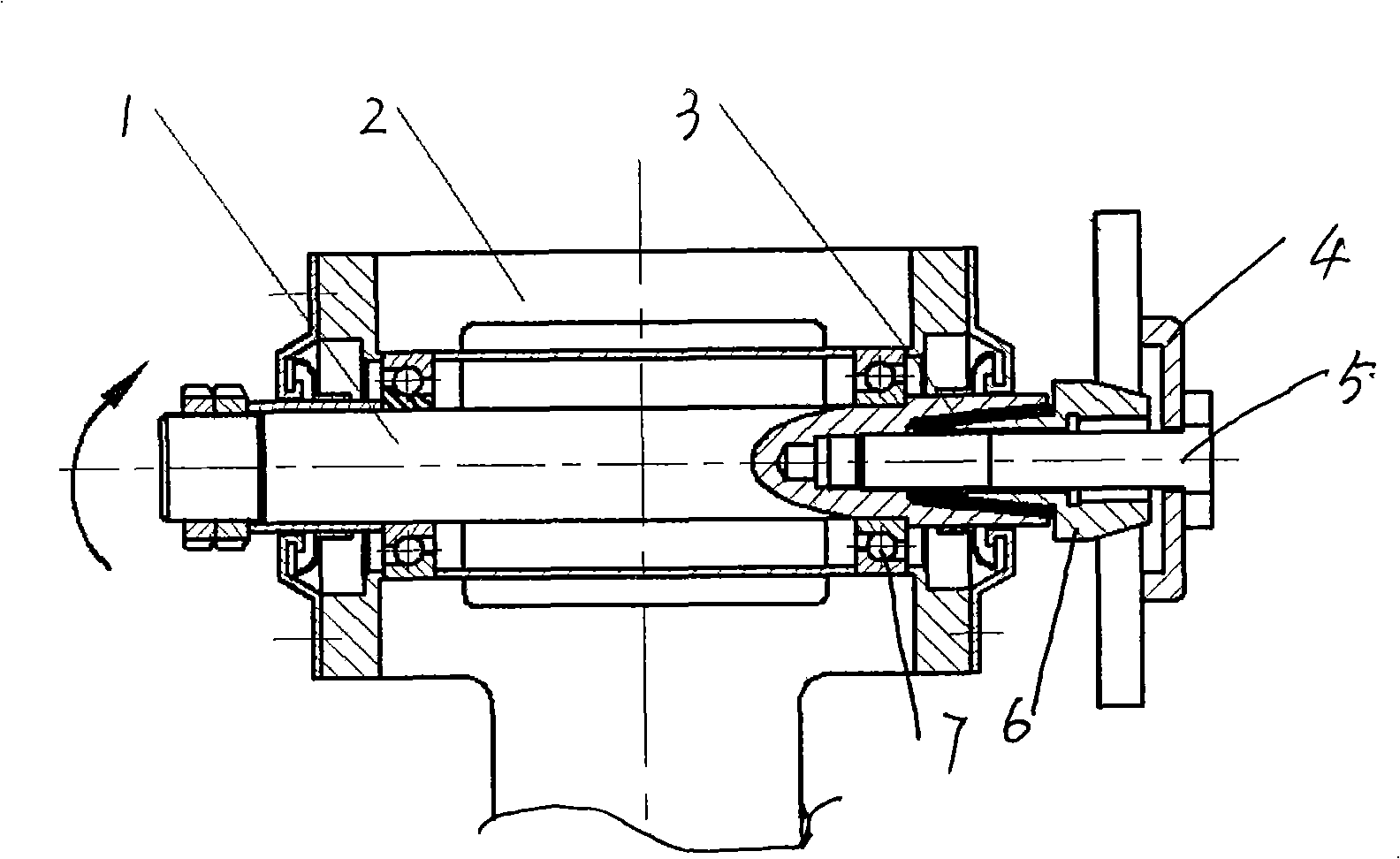

[0010] Such as figure 1 As shown, in the current-carrying friction and wear test equipment of the present invention, the friction sample fixture and the insulation structure of the equipment body, the friction sample fixture is fixedly assembled on the outer end of the transmission shaft, and the transmission shaft is assembled through the rotation of the bearing 7 and the bearing seat 2 On the equipment body, on the transmission shaft of the exposed section inside the fixed assembly position of the friction sample fixture, there is a disconnected surface, which divides the transmission shaft into two sections: the transmission shaft body section 1 and the end section 6, and the left and right transmission sections. The shaft and the shaft are fixed together, and an electrically insulating coating 3 is coated on at least one side of the broken surface. The preferred broken surface is a pair of concave and convex cone structures that cooperate with each other. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com