Direct crankshaft of air compressor

一种空气压缩机、曲轴的技术,应用在空气压缩机领域,能够解决不能具有、不能实现曲轴等问题,达到减少制造成本、提高经济效益的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] These and / or other aspects and advantages of the present invention will become clear and better understood through the following description of the embodiments. Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

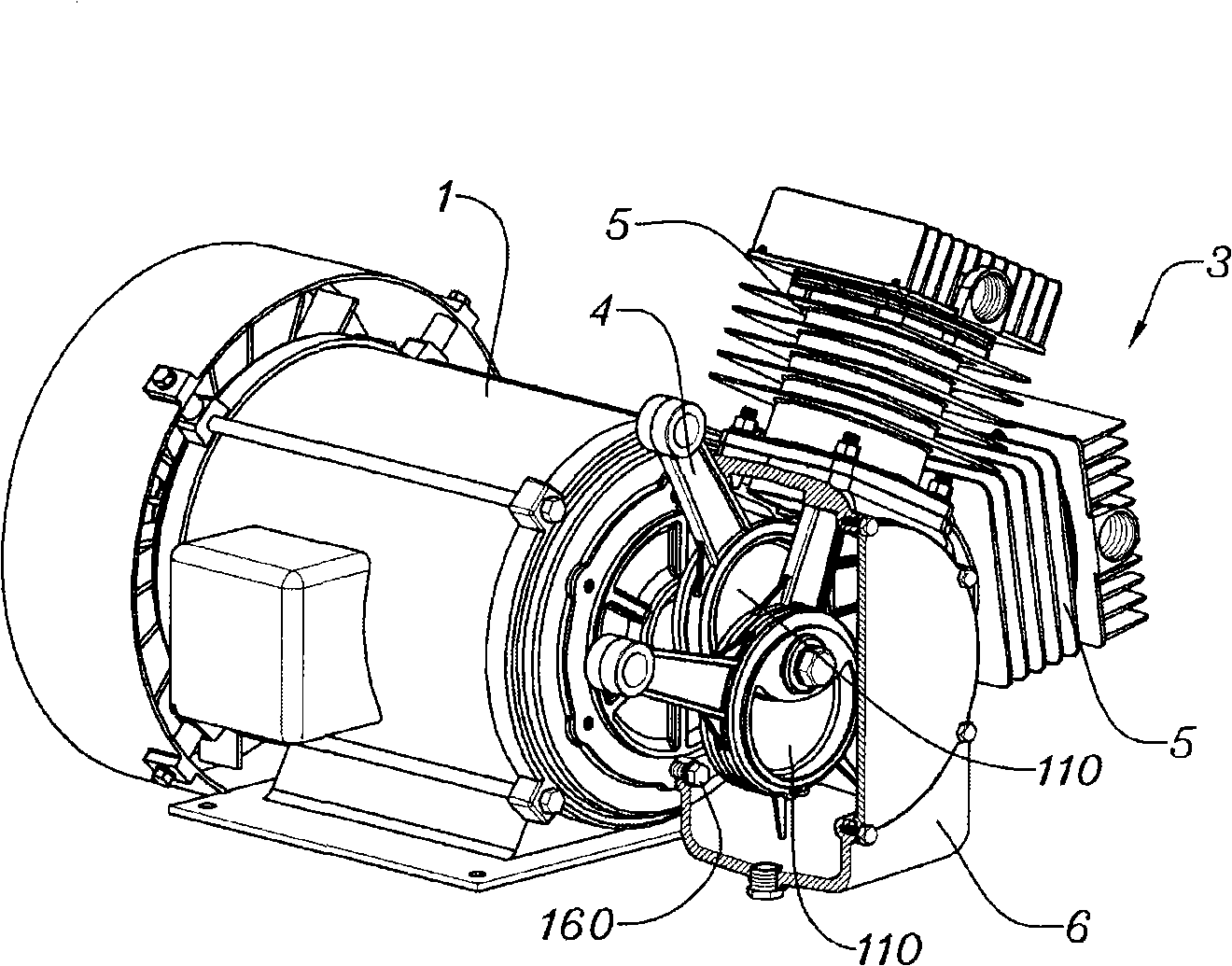

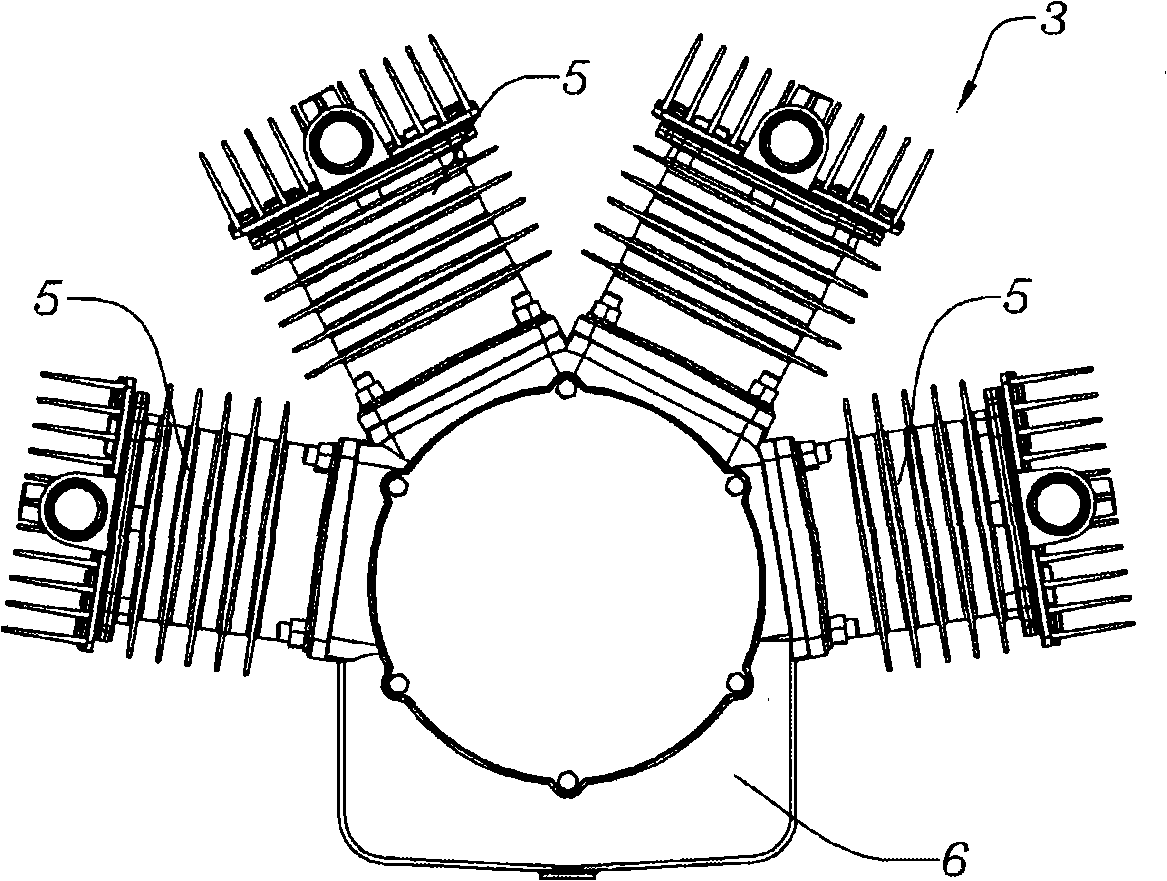

[0028] In the present invention, the compact straight-use crankshaft is directly installed on the motor, thereby having all the advantages of various traditional crankshafts. In the straight-use crankshaft of the present invention, the traditional standard crankshaft used in the piston air compressor is canceled. Balance weights and connecting members for connecting the link coupling units to each other are omitted.

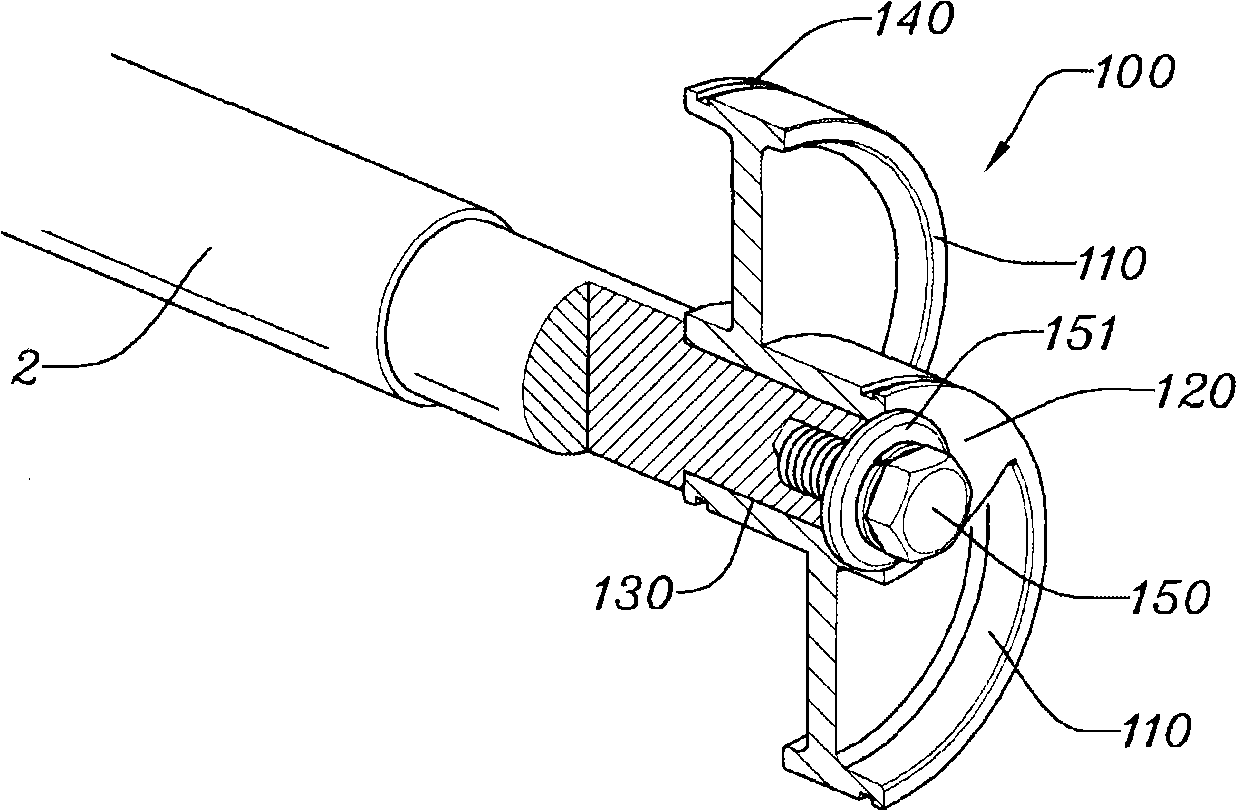

[0029] In order to realize above-mentioned aspect of the present invention, as image 3 and Figure 4 As shown, by combining a plurality of crankshaft plates 110 with each other to form a stacked unit 120, the stacked unit 120 has a shaft coupling hole 130, and the motor sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com