Contact lens package liquid

A contact lens and packaging liquid technology, applied in chemistry and other fields, can solve problems such as poor moisturizing effect, and achieve the effect of increasing moisturizing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

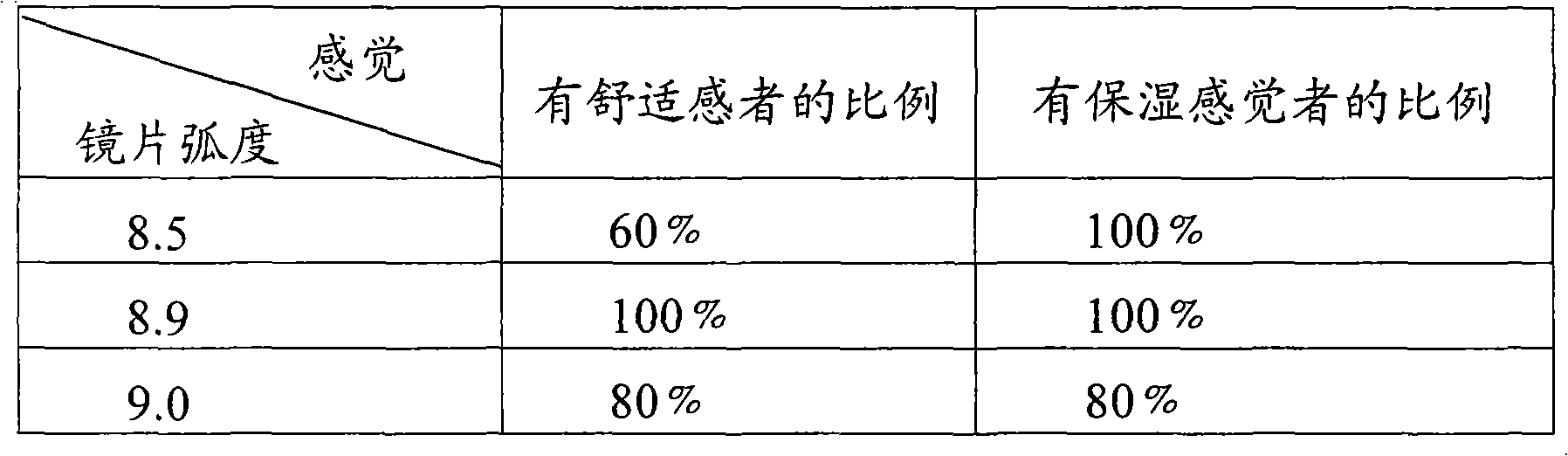

Image

Examples

Embodiment Construction

[0014] At present, many people use contact lenses to make up for their lack of vision, and some people use contact lenses to decorate their eyes. In general, among contact lenses, there are hard contact lenses mainly composed of methyl methacrylate, soft contact lenses containing 2-hydroxymethacrylate, and N-vinylpyrrolidone or silicone contact lenses. Glasses. Because soft contact lenses and silicone contact lenses have the advantages of short adaptation period, good oxygen permeability and comfortable wearing, they have become the mainstream of contact lenses.

[0015] The contact lens packaging solution of the present invention is basically applicable to any type of contact lens, as long as it does not cause substantial adverse effects on the lens. The contact lens packaging solution of the present invention comprises: a moisturizing ingredient containing sodium hyaluronate, the moisturizing ingredient is present in the packaging solution in an amount of 0.1 to 0.3% by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com