Filter cloth using polypropylene fiber silk as raw material and production method thereof

A technology of polypropylene yarn and filter cloth, which is applied in the field of filter cloth and its production, which can solve the problems of inapplicability to large-scale plate and frame filter presses, short service life, and low filtration accuracy, and achieve high strength, long service life, and high filtration accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

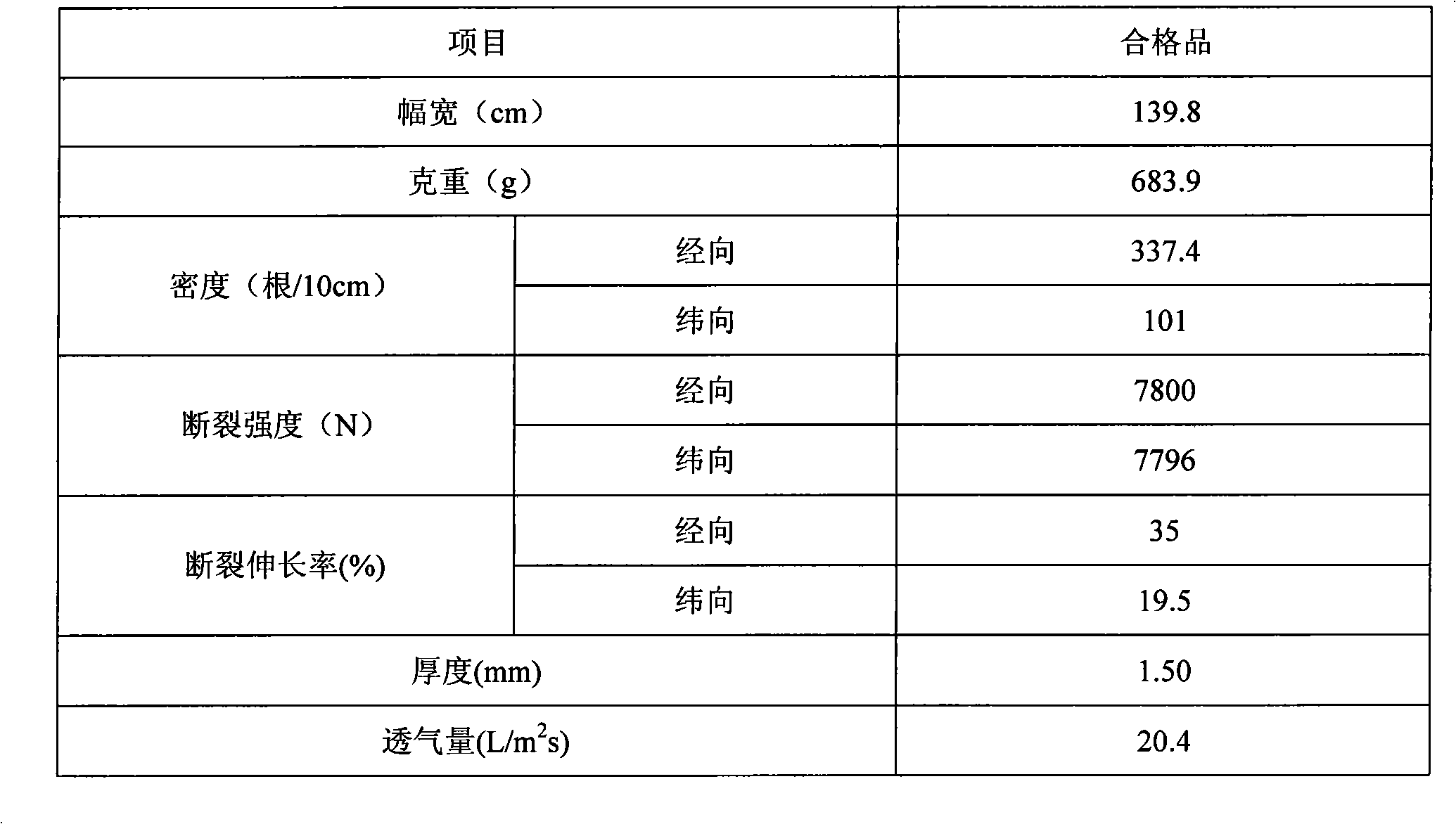

[0016] The width is 139cm, and its production steps are:

[0017] ①Materials: 500dtex polypropylene yarn is used as the warp material, and 1100dtex polypropylene yarn is used as the weft yarn material;

[0018] ② Use 500dtex polypropylene yarn as the warp raw material to make warp beams on the section warping machine;

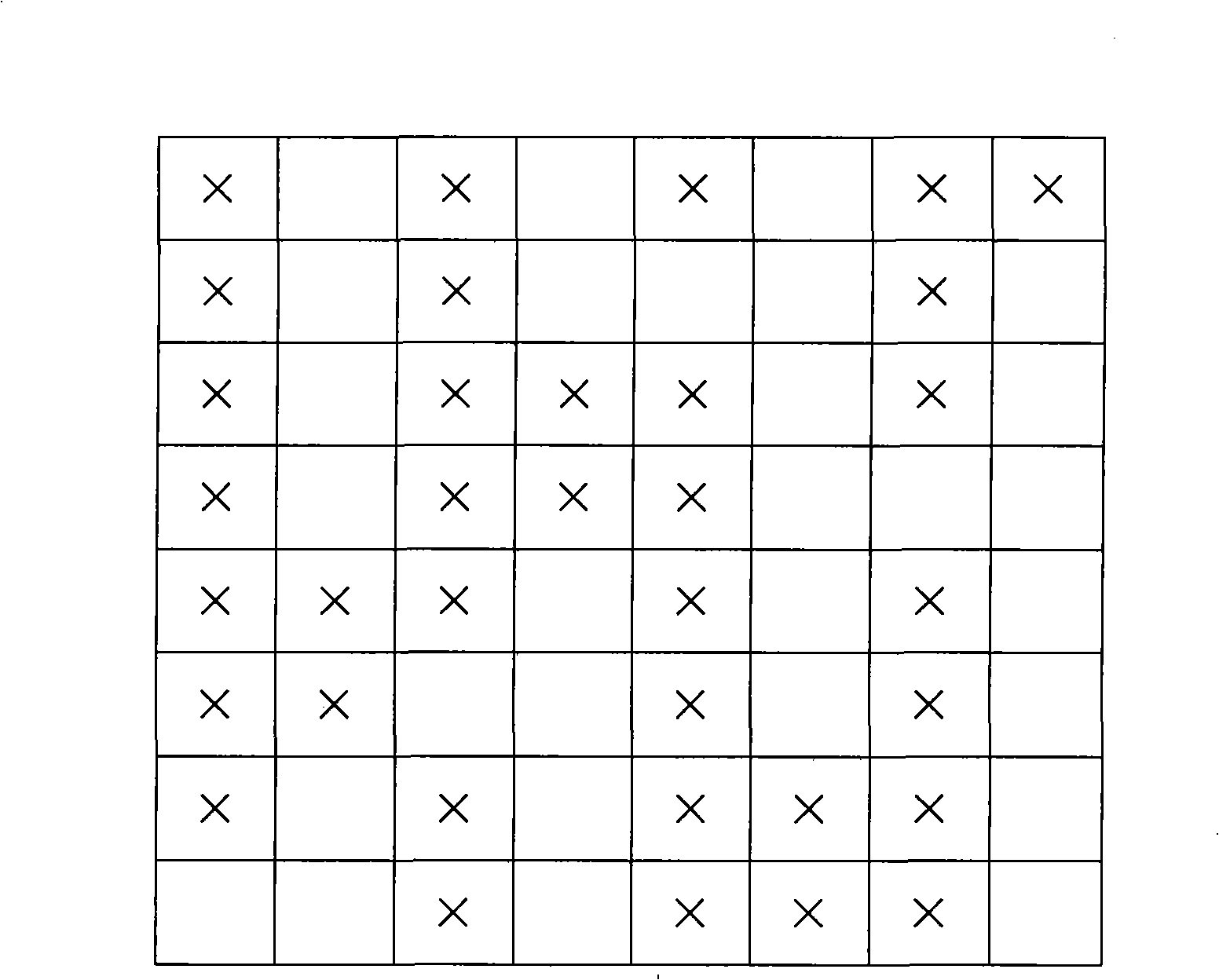

[0019] ③Use the warp beam and 1100dtex polypropylene yarn as the weft yarn on a wide-width rapier loom, and weave it in a dobby-opening manner to obtain a double-layer variable structure, such as figure 1 as shown, figure 1 Among them, × indicates that the warp line floats above the latitude line, which is called the warp tissue point. The single-layer warp density is 338 threads / 10cm, and the weft density is 100 threads / 10cm;

[0020] ④ The gray cloth off the machine is inspected and repaired, and then hot-rolled and shaped by a calender. The shaping temperature is 140 ° C, the shaping speed is 15-16 m / min, the hot-rolling pressure is 3000 N, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com