Portable electrodusting device

An electrostatic powder spraying and portable technology, applied in the field of metal surface coating, can solve the problems of large volume, complex structure of electrostatic powder spraying equipment, and large operating space requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

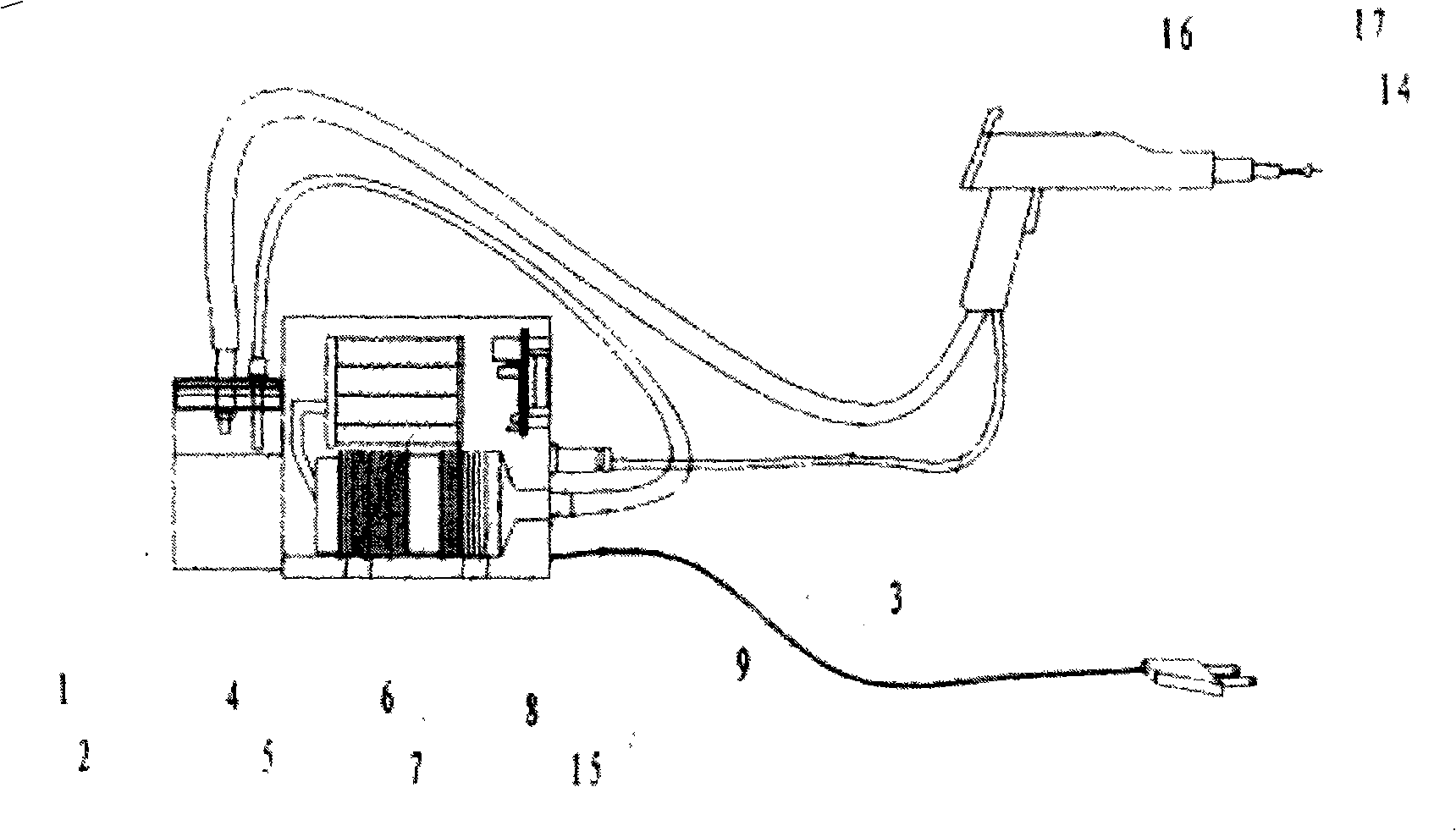

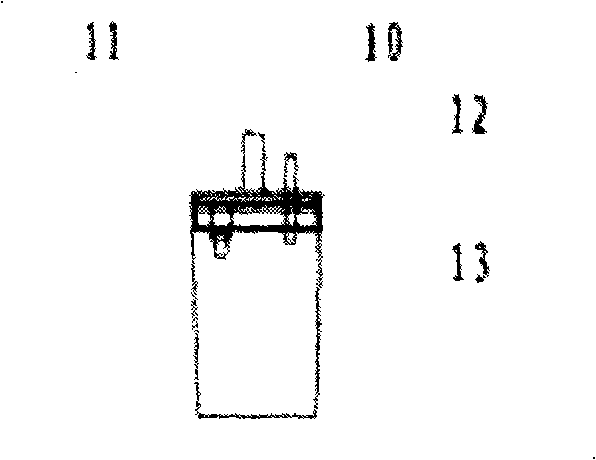

[0006] Specific embodiment: this portable electrostatic dusting equipment of the present invention is made of powder tank 1, electrostatic spray gun (handheld spray gun) 3, compressor 5 and air filter 4, and the output pipeline of compressor 5 is connected with powder tank 1 The inflation conduit is connected, and the powder conveying pipe 9 that outputs the mixed fluid of air and plastic powder from the powder tank 1 is connected with the electrostatic spray gun 3 . This design is realized in this way figure 1 Portable control box 2; electrostatic spray gun 3; air filter 4; small compressor 5; control drive board 6; control cable 7; air pipe 8; Powder tank 1 is made up of powder barrel 1 and sealing cover 12. Compressor 5, air filter 4 and control drive board 6 are arranged in the portable control box 2, and the powder tank 1 is hung on the outside of the portable control box. The portable control box 2 is provided with a compressor 5 and an air filter 4; the portable contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com