Single-plate slicing knife heating system

A heating system and planing knife technology, which can be used in wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc. Cut quality, eliminate effects beyond cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

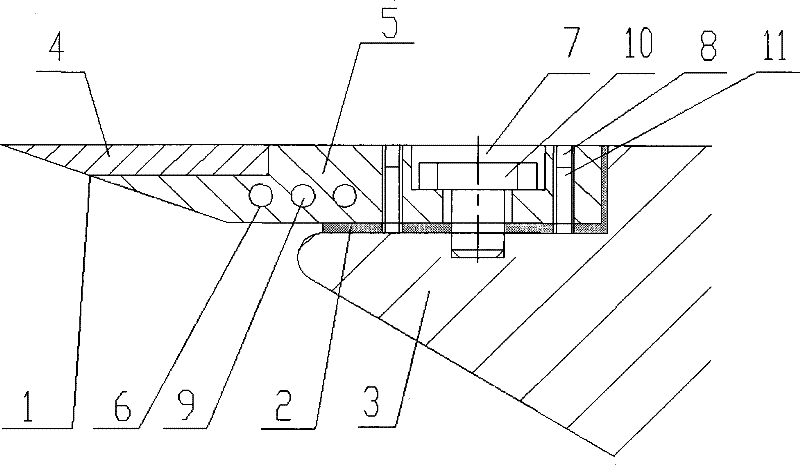

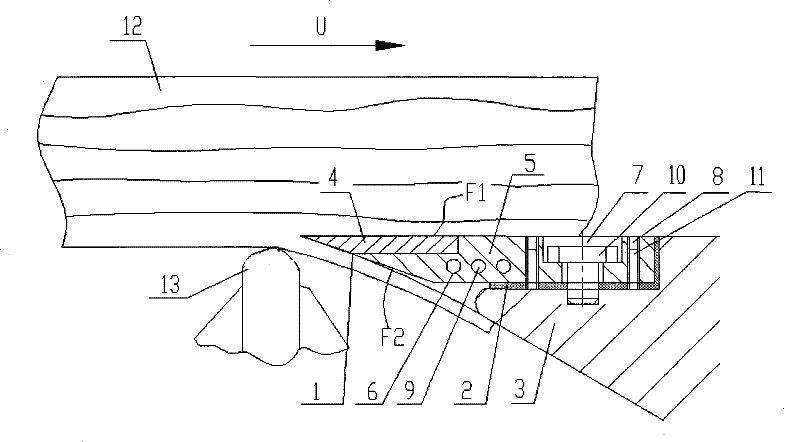

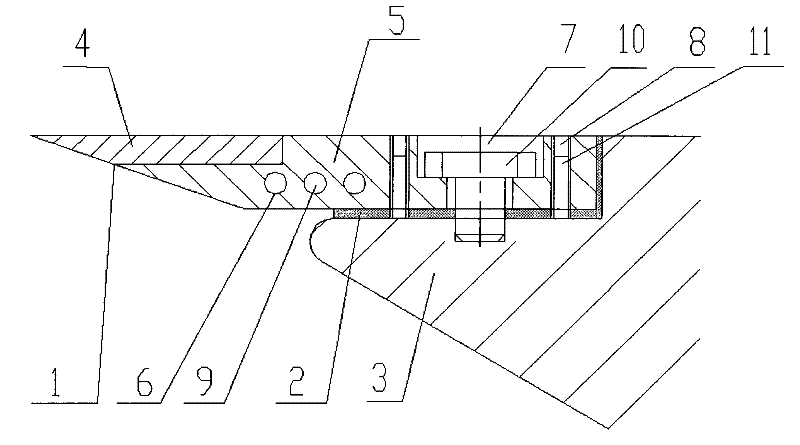

[0017] like figure 1 As shown, it is composed of a cutter body (1), a heat insulating medium (2) and a tool holder (3), and the cutter body (1) is welded into a whole by a cutting edge (4) and a base body (5). The cutter body (1) is provided with a locking hole (7) and an adjusting threaded hole (8). The heat insulation medium (2) is located between the cutter body (1) and the knife holder (3), and the space between the cutter body (1) and the knife holder (3) is adjusted by the adjusting screw (11) to determine the heat insulation medium (2) ), and then the position of the heat insulating medium (2) and the cutter body (1) is fixed by the locking screw (10). On the substrate (5) between the adjusting threaded hole (8) and the cutting edge (4), a return-shaped pipe (6) is processed. Heat transfer medium (9). The heat conduction medium (9) adopts hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com