High grade non- oriented silicon steel and method for manufacturing same

A technology of oriented silicon steel and a manufacturing method, applied in the field of metallurgy, can solve the problems of furnace roll nodules, high risk of use of floaters, and high cost, and achieve the effects of reducing energy consumption, reducing furnace roll nodules and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

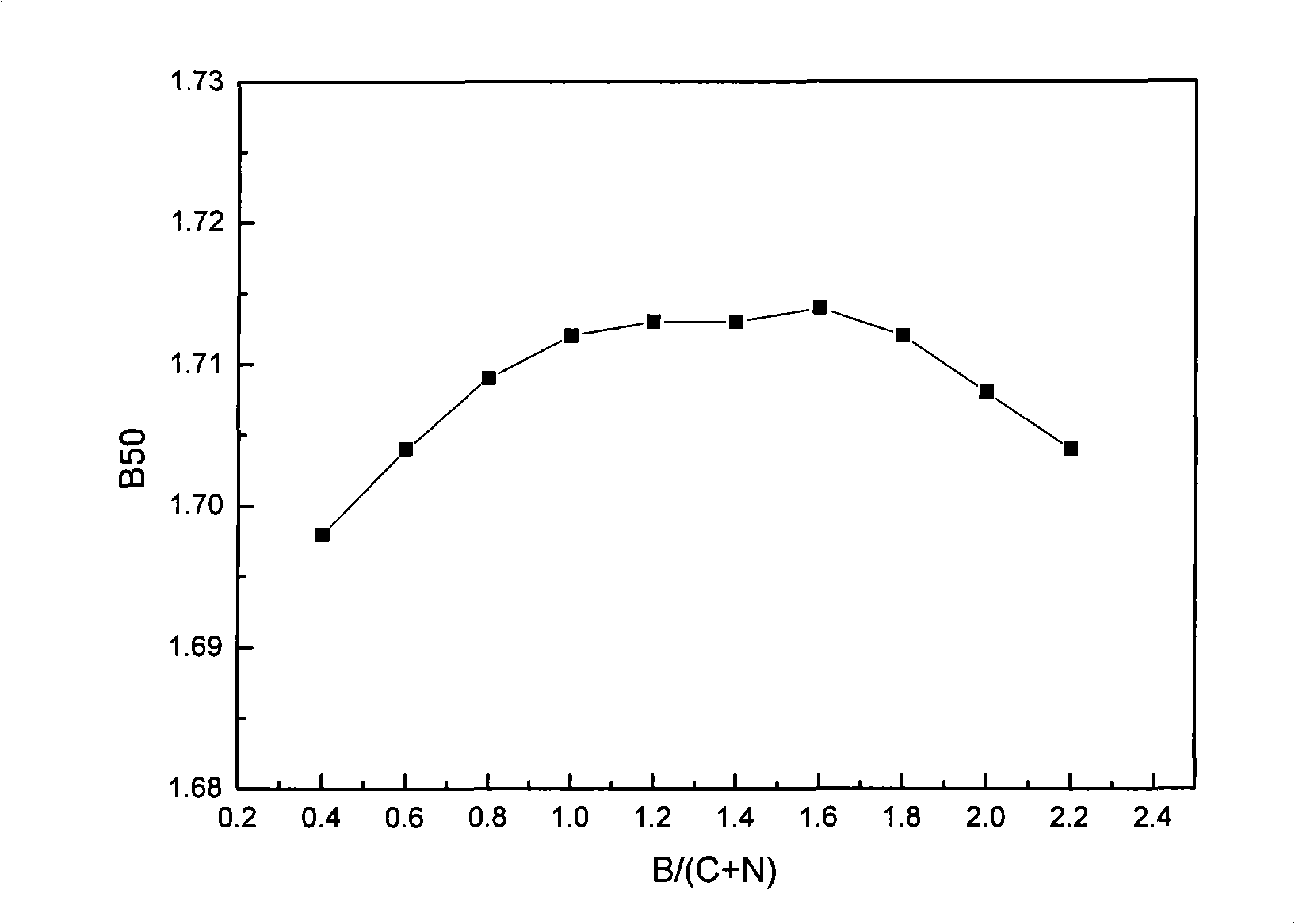

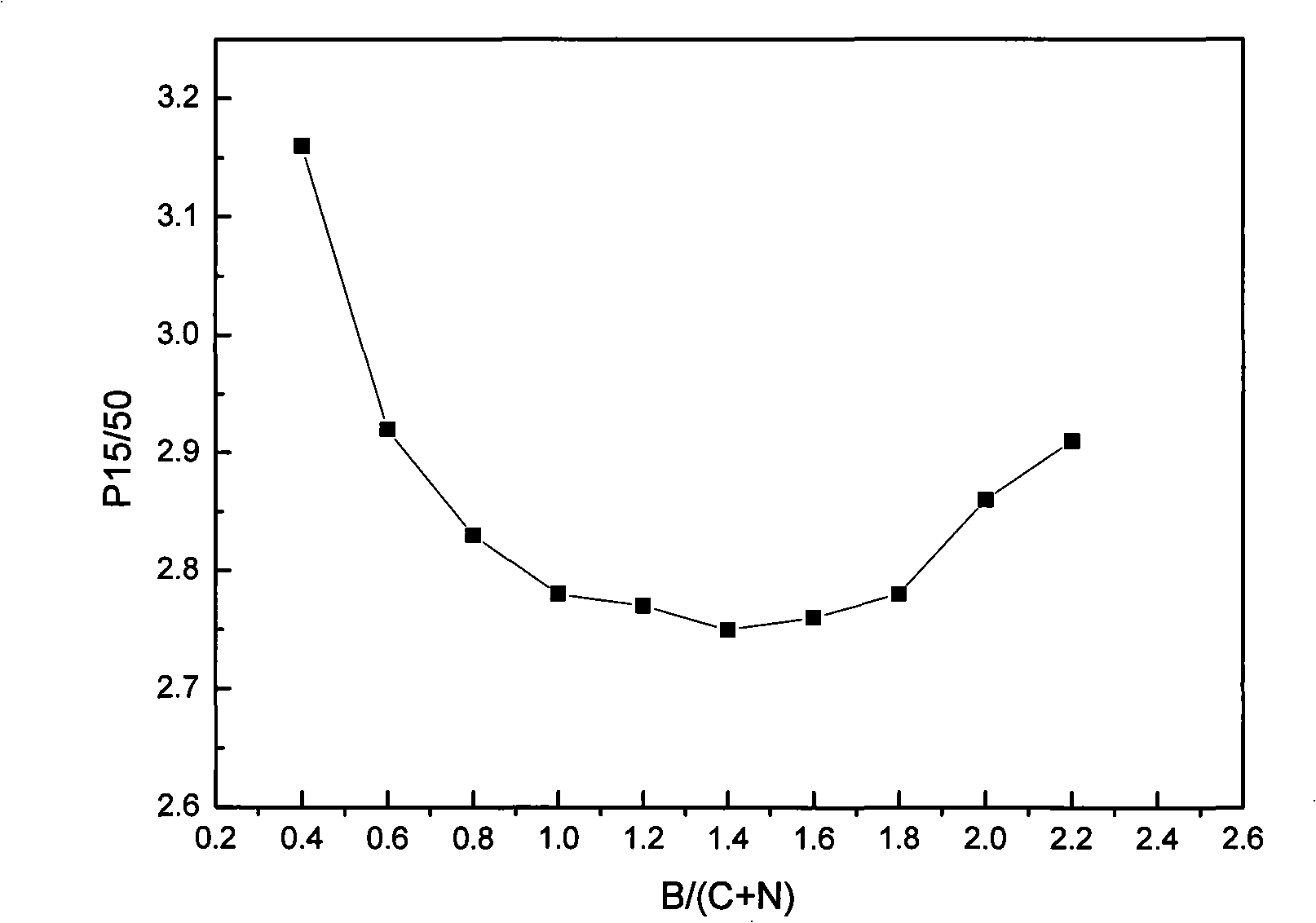

[0029] Smelt according to the components in Table 1, and obtain continuous casting slabs by continuous casting, continuous casting slab heating, rough rolling, finish rolling, regular treatment, pickling, 70-78% reduction ratio, one-time cold rolling to 0.5mm Finished thickness, final recrystallization annealing of cold rolled strip at different temperatures. Table 2 is the result of the chemical composition steel grades in Table 1 (corresponding to the furnace number) adopting the production method of the present invention and the finished product Epstein square circle.

[0030] Table 1 embodiment chemical composition (%)

[0031]

[0032] Table 2 embodiment production method and magnetic result

[0033]

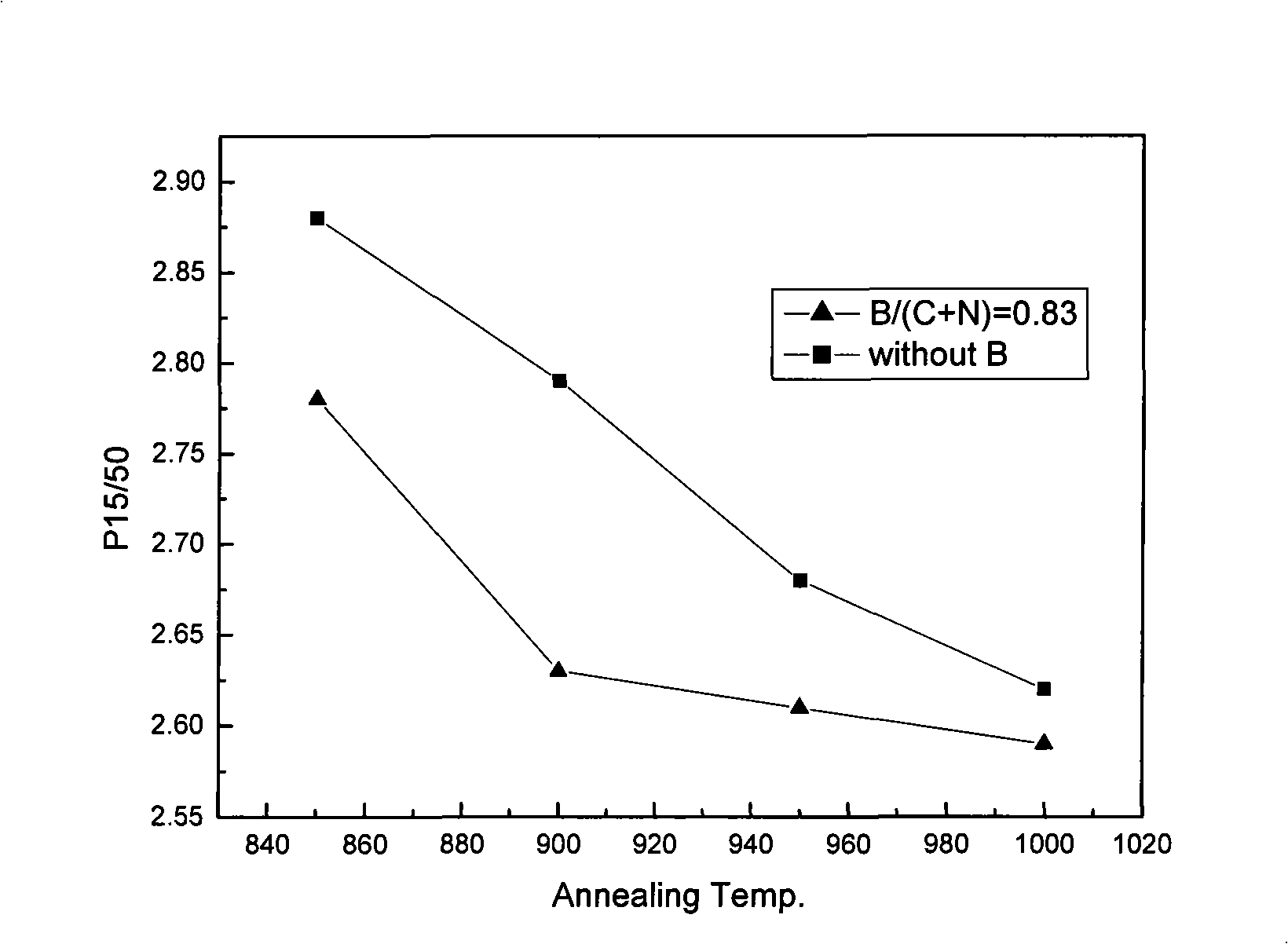

[0034] The components of furnaces 1, 2, 5, and 6 in Table 1 in the embodiment were processed according to the process shown in Table 3 for magnetic measurement, and the magnetic detection results are shown in Table 3.

[0035] Table 3 embodiment production method an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com